Use of jagged cutters

a cutter and cutter body technology, applied in the field of jagged cutters, can solve the problems of difficult restrippability of adhered tapes, and achieve the effect of easy and smooth tearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

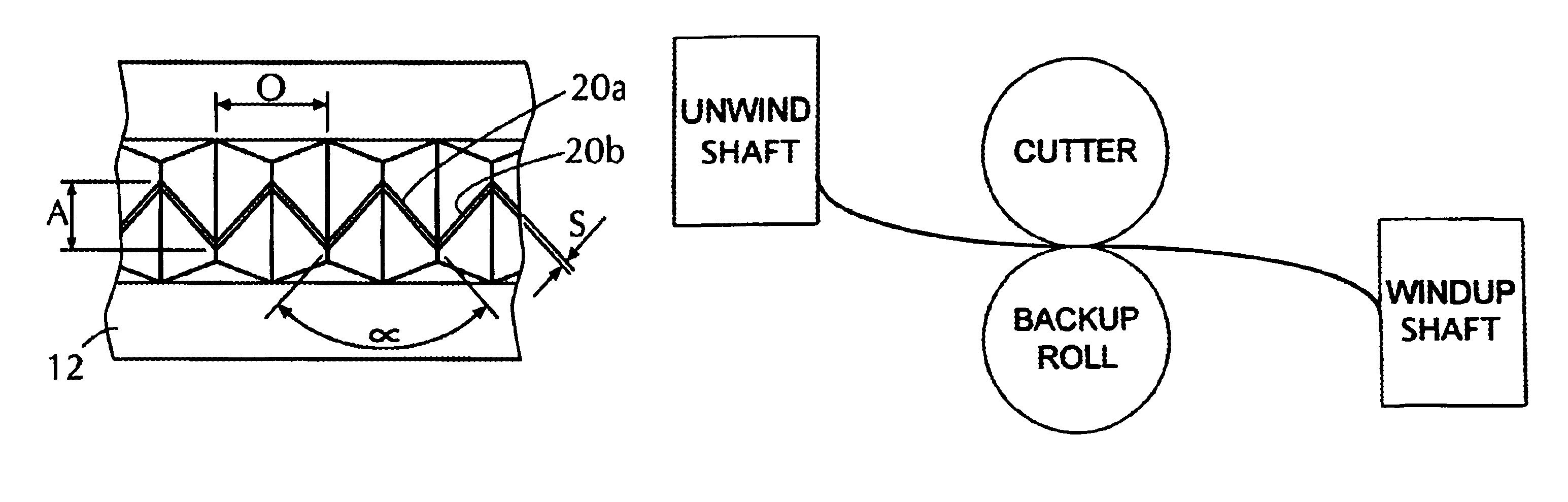

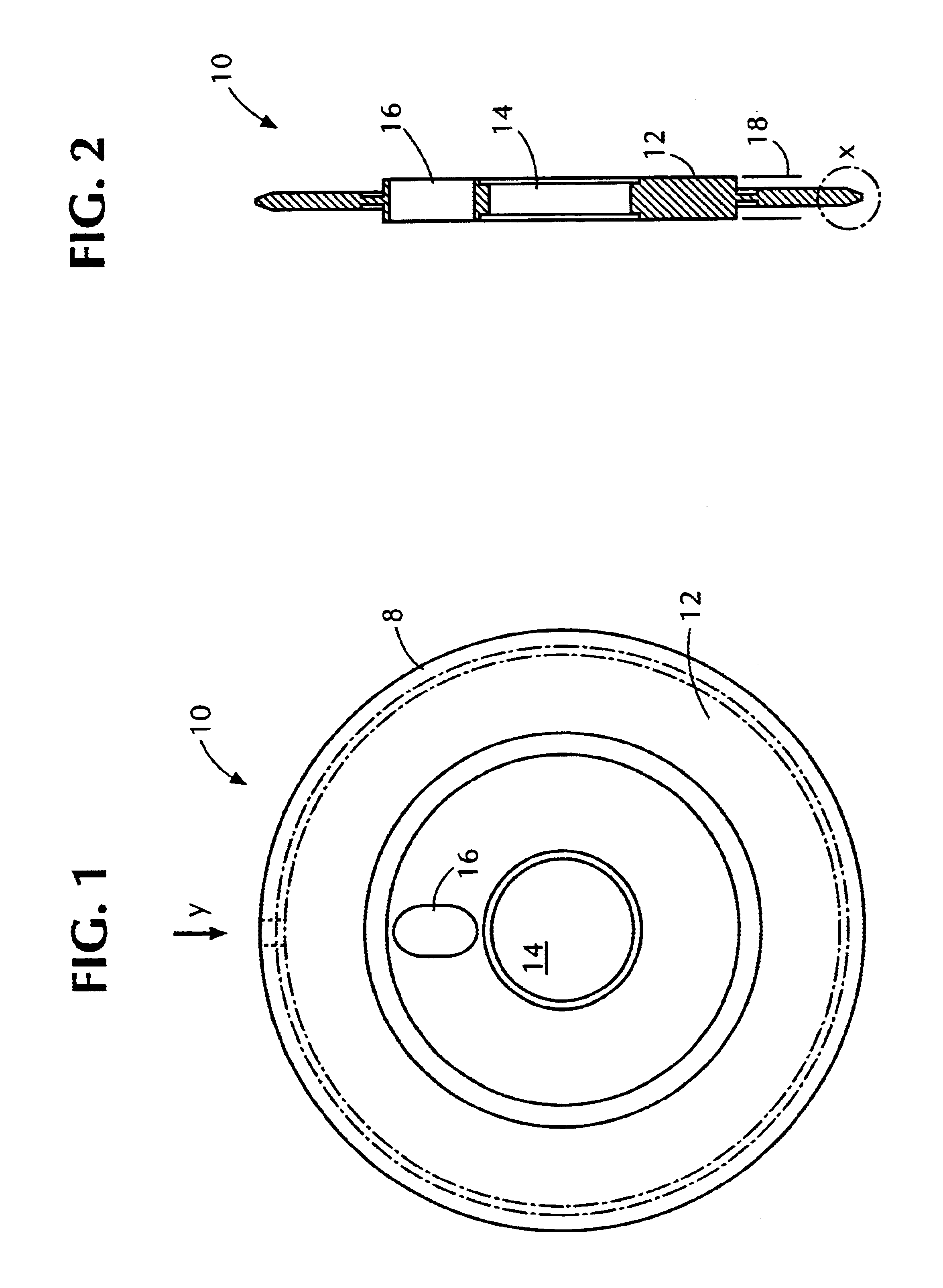

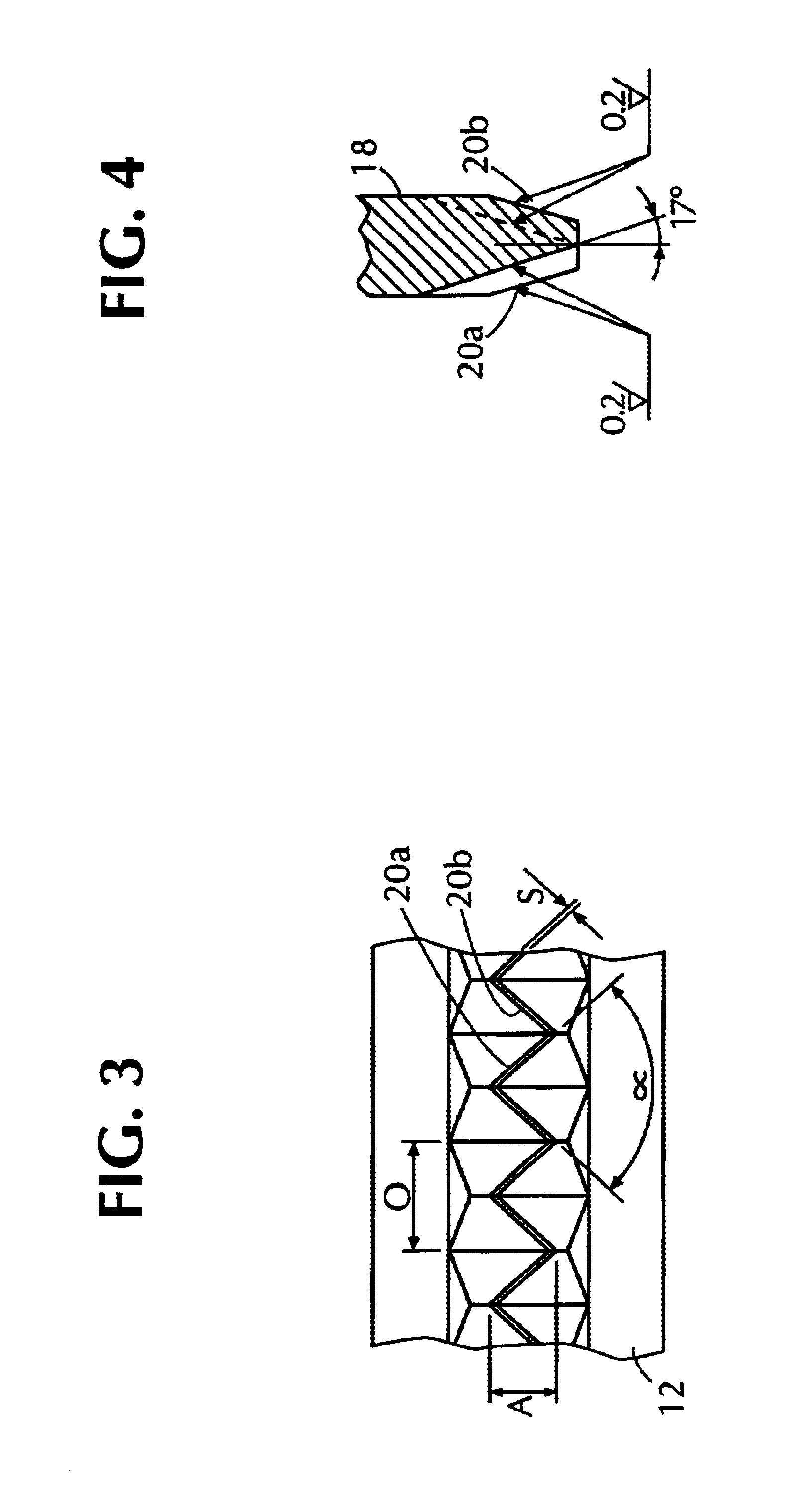

jumbo roll of 1,000 m length and 1,050 mm width, mounted on a 50 .mu.m biaxially stretched PP backing, coated on both sides with 100 g / m.sup.2 of rubber self-adhesive composition and covered on one side with a silicone-treated release paper, is cut up into saleable rolls. The longitudinal cuts are made by means of crush cutters against a steel roll. The crush cutters are specially ground to obtain a jagged cut. Cutters of this kind are available from Alcon Tools, Ohio, USA. The jag height of the cutters is 0.5 mm, the peak angle of a jag is 90.degree.. The further cutting parameters are unchanged with respect to the standard process: cutting rate 100 m / min., winding tension remains uniform without, in the process, additional machine stops occurring as a result of unintended tears.

With the use of this macroscopic jagged cutter, edge tearability is achieved even though the PP film is cut through the adhesive composition and release paper against a steel cylinder.

The carpet fixing tape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| jag height | aaaaa | aaaaa |

| jag height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com