Sweeping assembly, cleaning appliance, and method for cleaning appliance

a technology for cleaning appliances and cleaning brushes, applied in the direction of brushes, suction cleaners, domestic applications, etc., can solve the problems of increasing the rotational friction in the region, affecting the rotational speed of the sweeping brush, so as to achieve the effect of reducing the shortcomings of the prior ar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

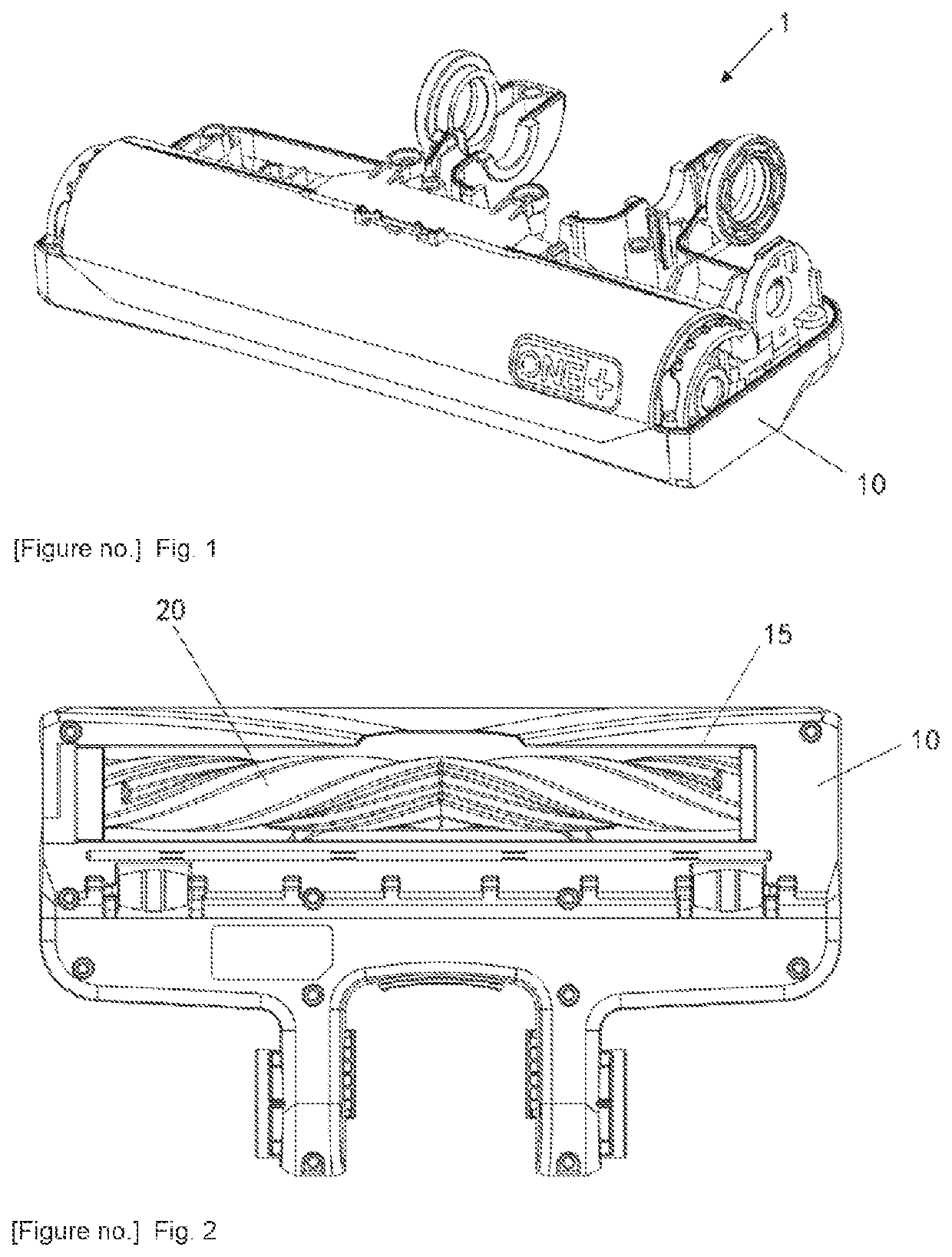

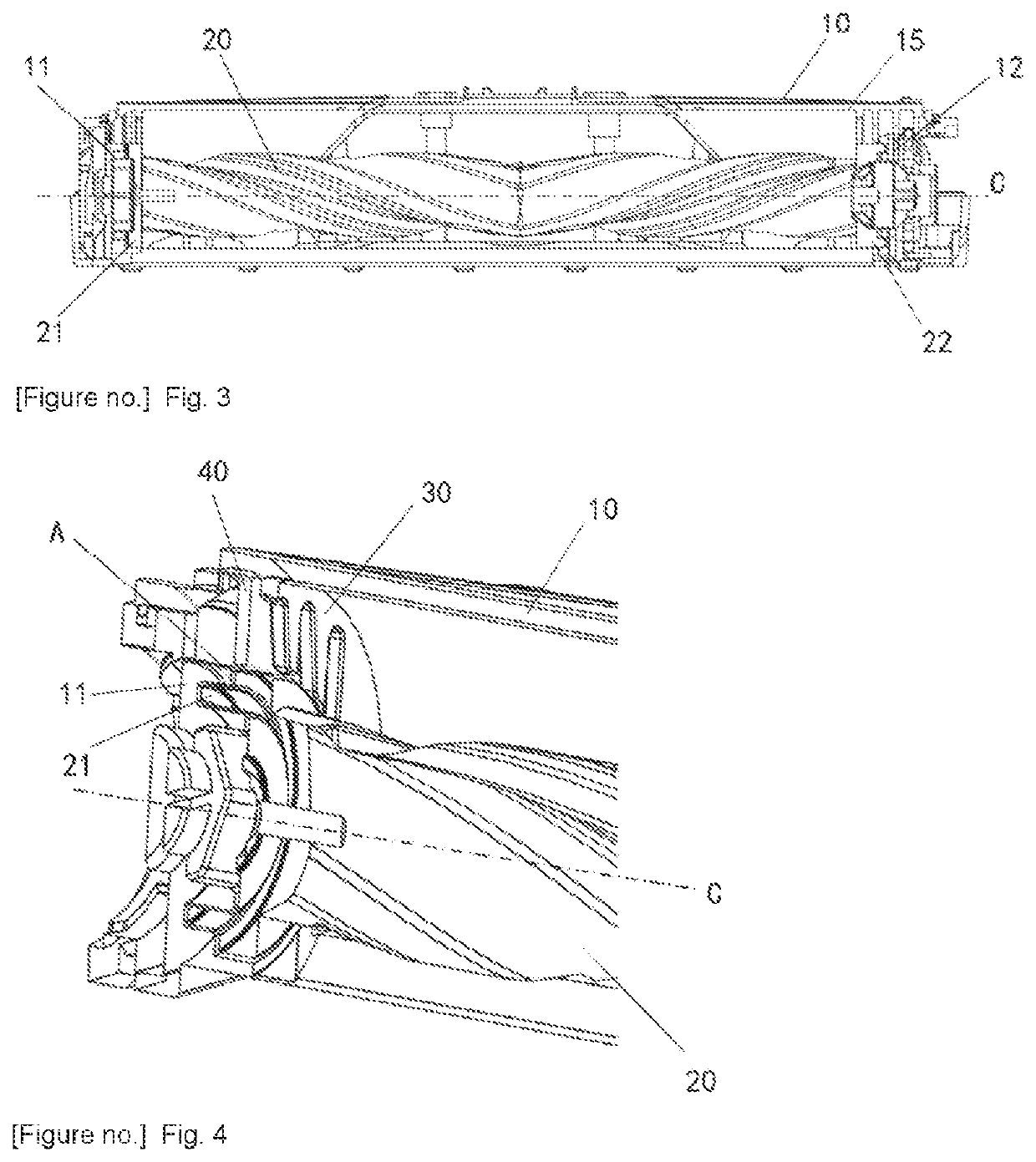

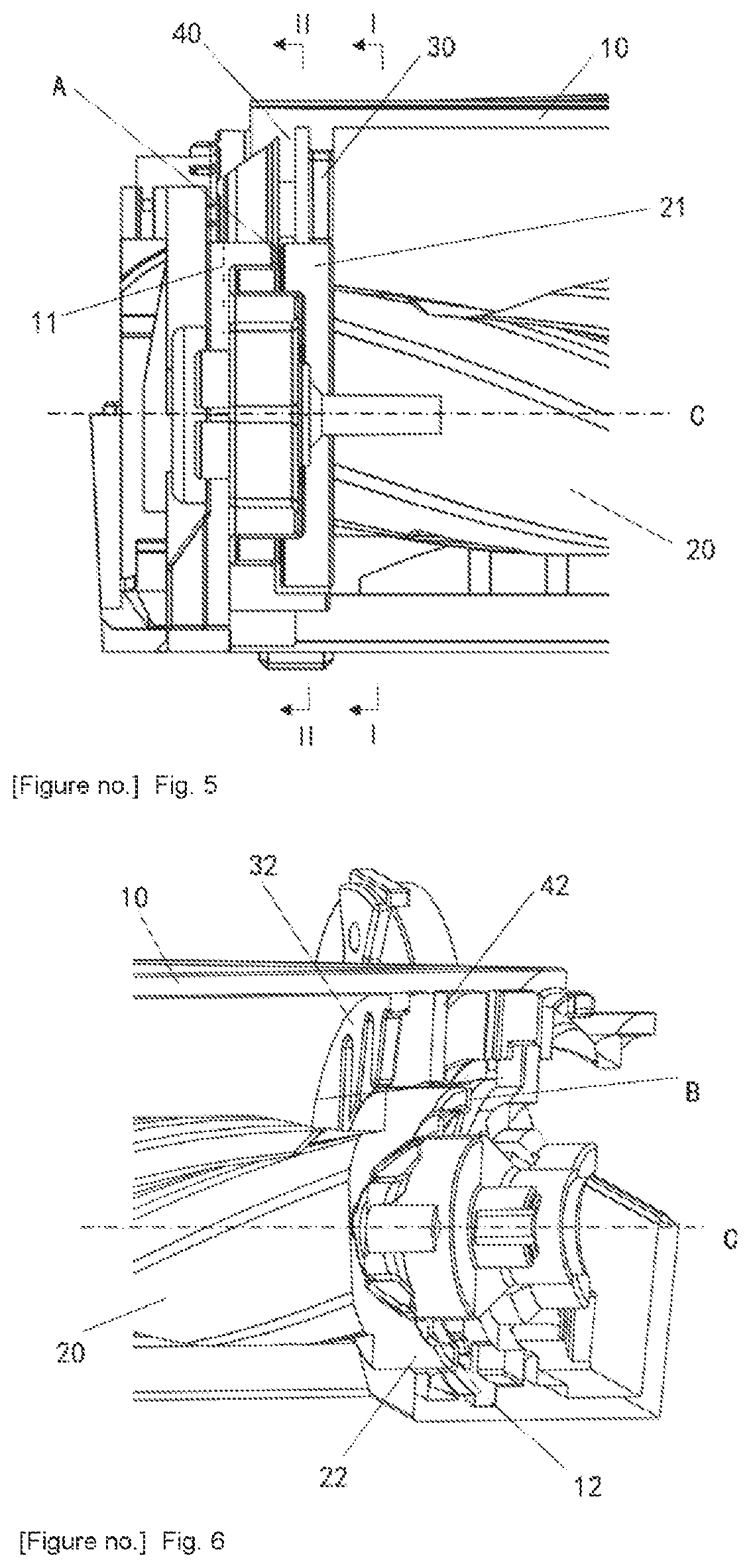

[0027]FIG. 1 shows a particular embodiment of the sweeping assembly according to the present invention. FIG. 2 shows a bottom view of the sweeping assembly in FIG. 1. FIG. 3 shows a sectional drawing of the sweeping assembly in FIG. 1.

[0028]Referring to FIGS. 1-3, the sweeping assembly 1 comprises a housing 10 forming an external appearance and a sweeping brush 20 accommodated in the housing 10. An opening 15 is formed in a bottom face of the housing 10; foreign matter can be swept or sucked into the sweeping assembly 1 through the opening 15. In this embodiment, the sweeping brush is a roller, with bristles provided on a surface thereof. It should be understood that the sweeping brush may also be any form of structure capable of performing a sweeping function. The sweeping brush 20 is rotatably mounted in the housing 10, and exposed to a surface to be cleaned through the opening 15. The sweeping brush 20 can receive a driving force from a drive source and thus rotate about a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com