Heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

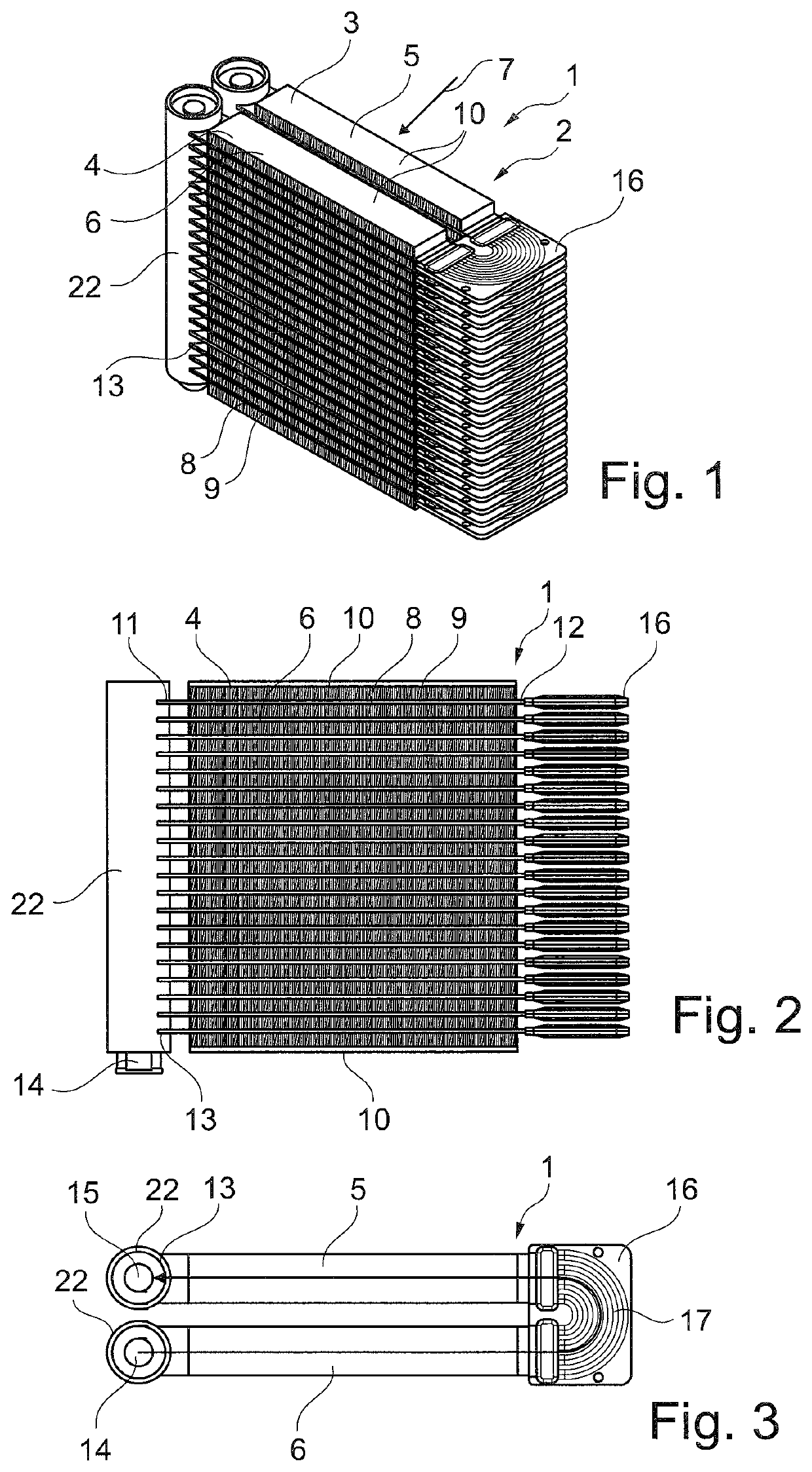

[0025]The FIGS. 1 to 3 show different views of an embodiment of a heat exchanger 1.

[0026]The heat exchanger 1 is in this shown embodiment a heat exchanger of a refrigerant cycle of the air-conditioning system of a motor vehicle or for residential and / or commercial application, e.g. for the use for residential or non-residential buildings etc. The heat exchanger may be e.g. an evaporator or a condenser.

[0027]Nevertheless the heat exchanger 1 might be another heat exchanger e.g. of a cooling cycle of a motor vehicle or of a residential or commercial application, like a heater core, a radiator or something different like an oil cooler or the like.

[0028]The heat exchanger 1 is a two-row heat exchanger having a heat exchanger core 2 having two rows 3, 4 of tube and fin blocks 5, 6.

[0029]A first tube and fin block 5 is provided and additionally a second tube and fin block 6 is provided which are arranged just adjacent to each other and which are approached by an air flow 7 one after the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com