Electronic cigarette and method for manufacturing component thereof

a technology of electronic cigarettes and components, applied in tobacco, applications, food science, etc., can solve the problems of plastic melting, other risks, affecting human health, etc., and achieve the effects of reducing the likelihood of inhaling toxic substances, eliminating the utilization of adhesives, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0051]FIG. 6 is a perspective view showing the mechanism of coupling the electronic cigarette 100 of the first embodiment to a supporter 130.

[0052]Referring to FIG. 6, the electronic cigarette 100 of the present application may further comprises the supporter 130. The supporter 130 is capable of supporting the electronic cigarette 100.

[0053]FIG. 7A is a perspective view of an electronic cigarette 200 of a second embodiment. FIG. 7B is a perspective view of a cartridge of the electronic cigarette 200 of the second embodiment. FIG. 7C is a cross-sectional view of the cartridge of the electronic cigarette 200 of the second embodiment.

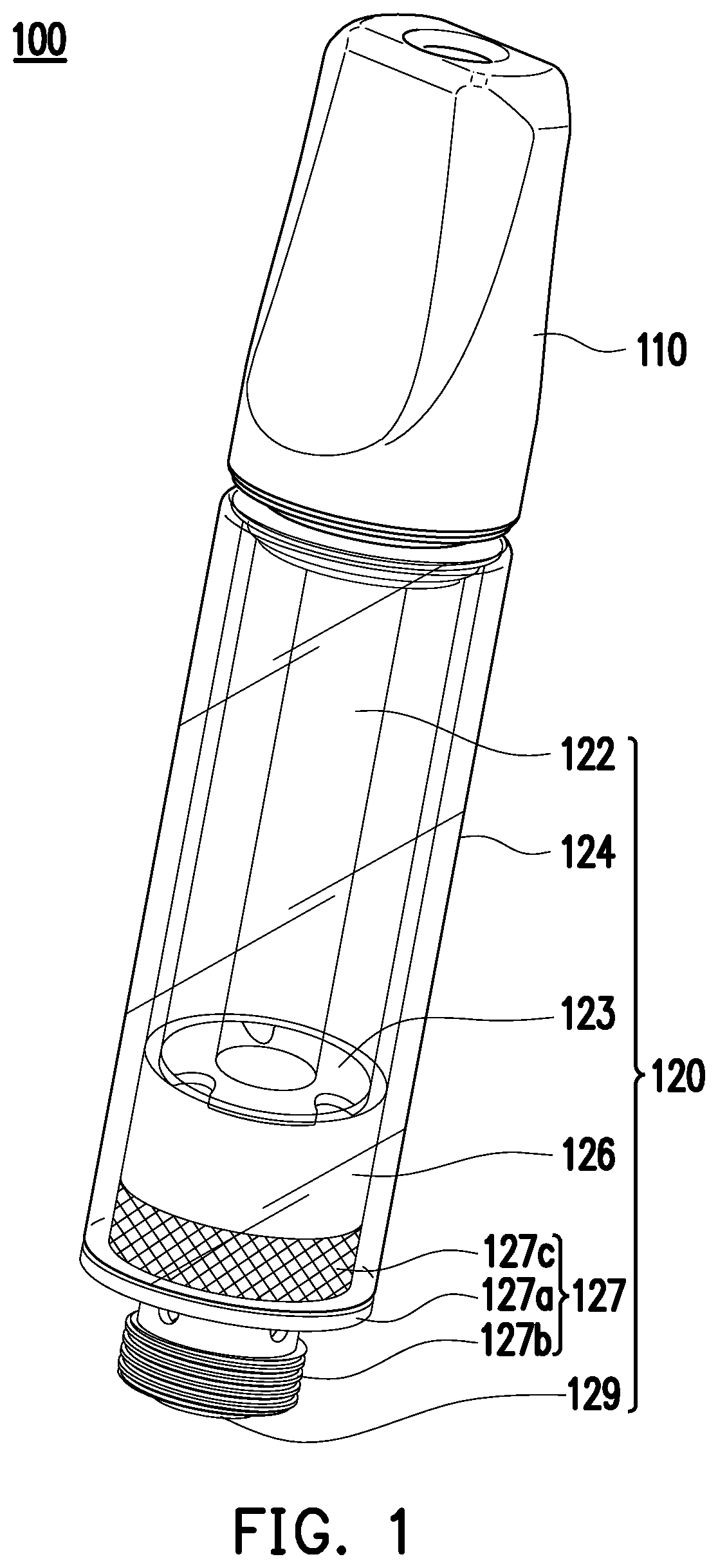

[0054]Referring to FIGS. 7A-7C, the electronic cigarette 200 comprises a mouthpiece 210 and a tank 220. The tank 220 comprises a fixer (not separately illustrated), a cartridge, a sealer (not separately illustrated), an atomizer 226, a base 227, a sealer (net separately illustrated) and an adapter 229.

[0055]The cartridge comprises an air duct 222, a plate ...

third embodiment

[0059]FIG. 8 is a cross-sectional view of a cartridge of an electronic cigarette 300 of a

[0060]The cartridge comprises an air duct 322, a plate 323 and an oil cup 324. The plate 323 comprises at least one hole 323a and external thread. The oil cup 324 comprises a lower oil cup 324a and an upper oil cup 324b. The lower oil cup 324a comprises an internal thread for the external thread of the plate 323 and an internal thread for the atomizer. The difference between the cartridge of the electronic cigarette 300 and the cartridge of the electronic cigarette 200 is that the plate 323 is threaded to the lower oil cup 324a rather than being welded.

[0061]FIGS. 9A-9B shows the experimental data between different material of cartridge.

[0062]Referring to FIG. 9A. the specimen in FIG. 9A is general brass of a mouthpiece for electronic cigarette. The test is examined with reference to IEC62321-4:2013+A1:2017, IEC62321−5:2013, IEC62321−7−1:2015 and is analyzed by ICP-OHS and UV-Vis.

[0063]1 mg / kg i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com