Bast crops processing line

a technology for bast fiber crops and processing lines, applied in the direction of mechanical fibre separation, textiles and papermaking, mechanical treatment, etc., can solve the problems of high energy and metal intensity of processing lines, complicated process of shives separation, and inability of spiked feeders to perform carding and scutching functions, etc., to achieve less metal and energy-consuming equipment, less stringent processing modes, and less power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

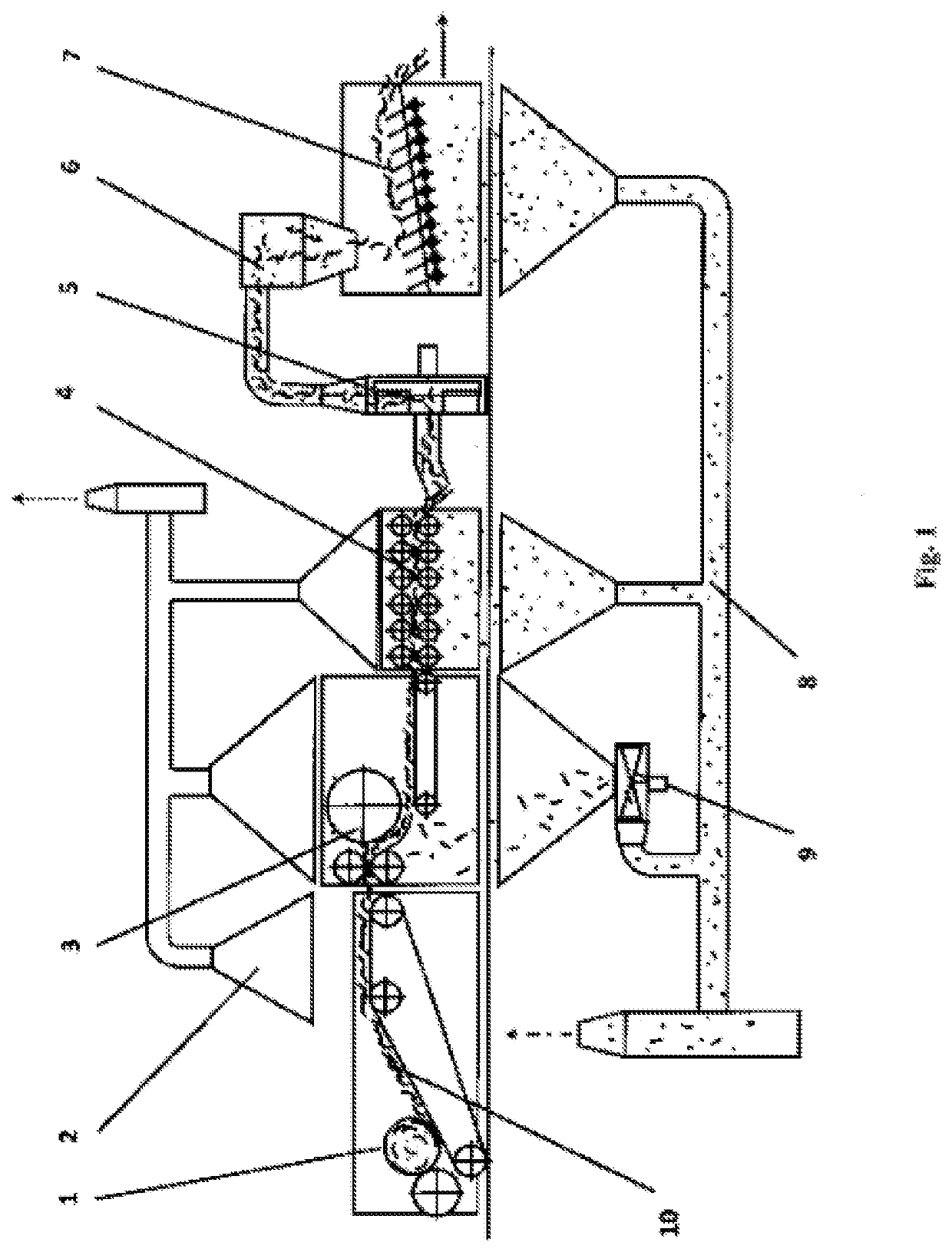

[0021]The processing line works as follows: the raw material (10) from the recoiling machine (1) is fed into the layer-forming and scutching machine (3), where the layer of raw material (10) is first thinned, then the raw material (10) is scutched and carded and after that separation of shives and raw material (10) is performed. The formed layer of raw material (10) passes to the breaking machine (4), where its intensive breaking with simultaneous drawing, abrasion and thinning is performed. The crushed and partly separated from the shive raw material (10) enters the machine for scutching raw fibers without pressing (5), where the stator and rotor's blades (not shown on the drawing) intensively separate shives from fibers and break long bast fibers into shorter ones. Then, the shive-fibre mix passes to the cyclone separator (6), where it is separated from the air flow created by the machine for scutching raw fibers without pressing (5). From the cyclone separator (6), the shive-fibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com