Method for Depositing Noble Metal to Carbon Steel Member of Nuclear Power Plant and Method for Suppressing Radionuclide Deposition on Carbon Steel Member of Nuclear Power Plant

a nuclear power plant and carbon steel technology, applied in the direction of liquid/solution decomposition chemical coating, corrosion prevention, superimposed coating process, etc., can solve the problems of radiation exposure of workers during regular inspection work, traces of metal impurities that have not been removed, and accumulated radionuclides. , to achieve the effect of increasing the amount of electrons, increasing the dissolution of iron ions, and increasing the amount of nickel ions incorporated into the surface of the carbon steel member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

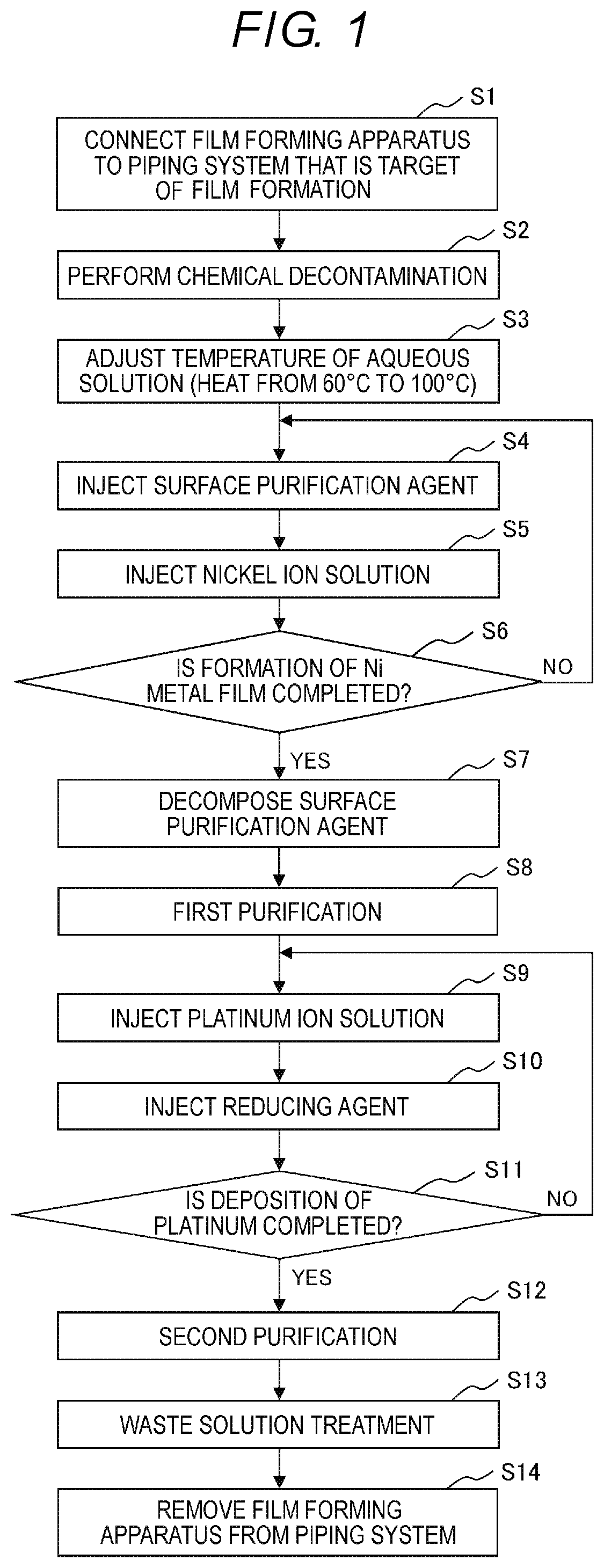

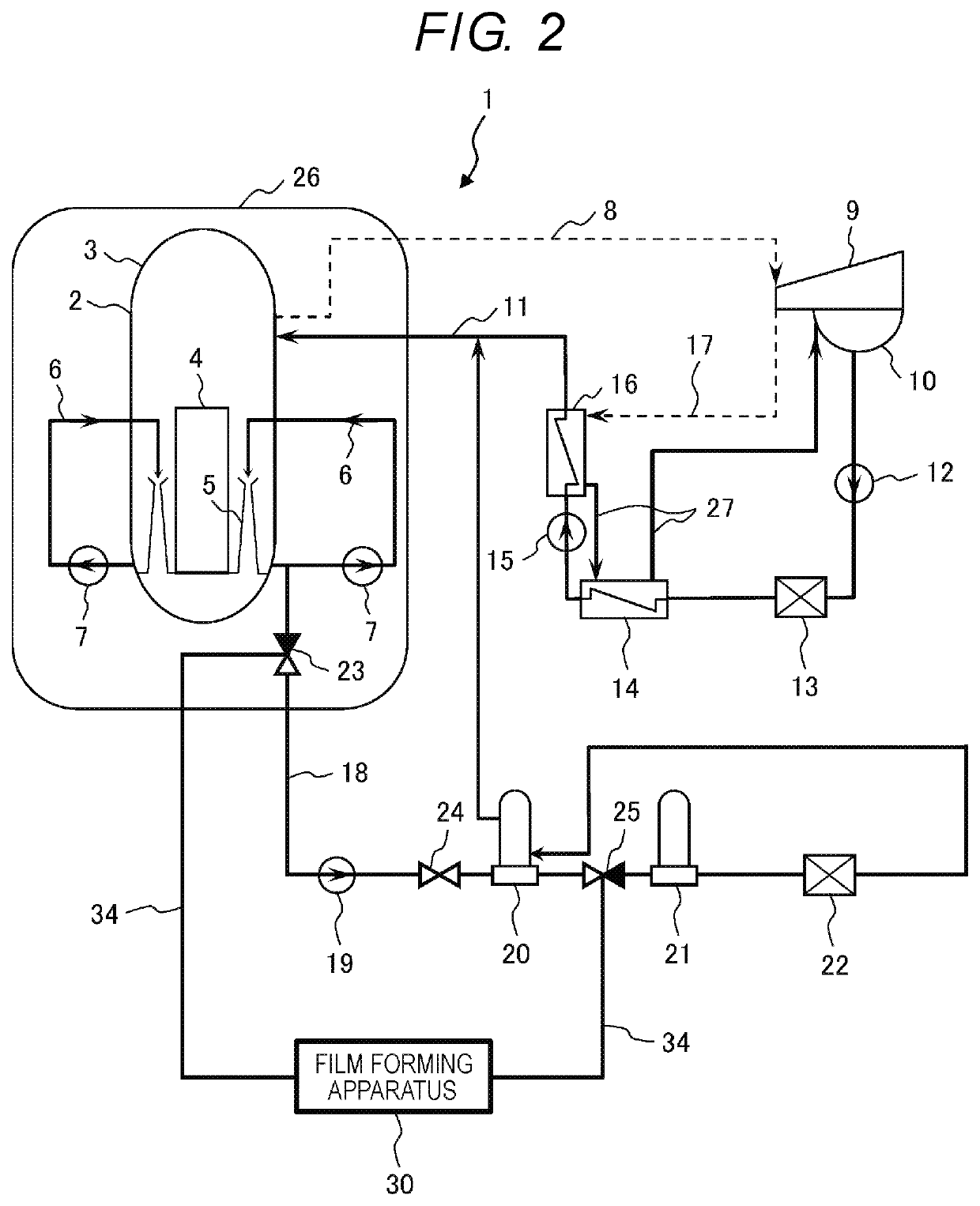

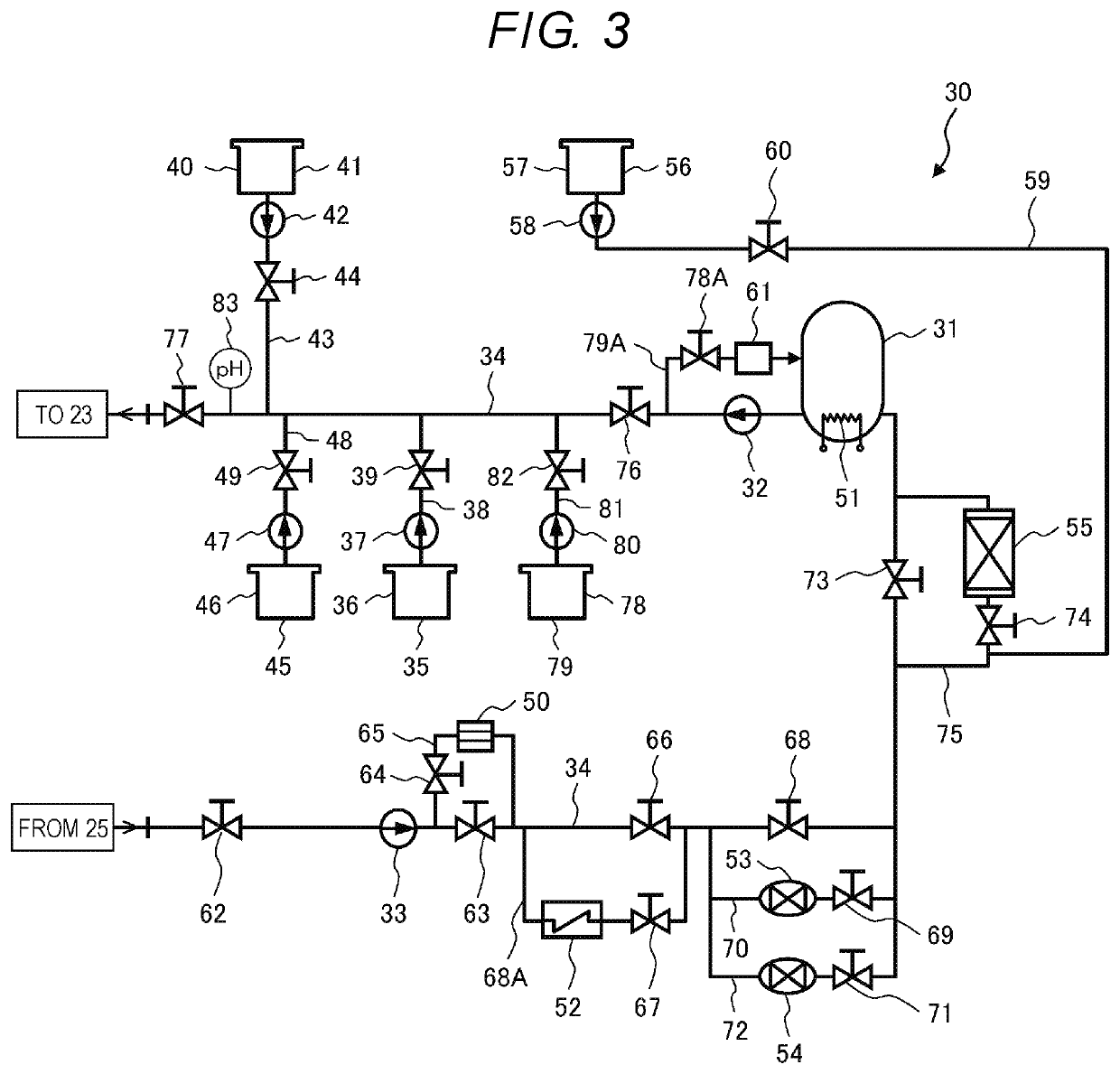

[0065]A method for depositing a noble metal on a carbon steel member of a nuclear power plant according to a first embodiment, which is a preferred embodiment of the present invention, will be described with references to FIGS. 1, 2, and 3. The method for depositing a noble metal on a carbon steel member of a nuclear power plant according to the present embodiment is applied to a carbon steel purification system piping (carbon steel member) of a boiling water type nuclear power plant (BWR plant).

[0066]A schematic configuration of the BWR plant will be described with reference to FIG. 2. The BWR plant 1 includes a nuclear reactor 2, a turbine 9, a condenser 10, a recirculation system, a nuclear reactor purification system, a feedwater system, and the like. The reactor 2 includes a reactor pressure vessel (hereinafter referred to as RPV) 3 in which a reactor core 4 is built, and includes a plurality of jet pumps 5 installed in an annular downcomer formed between an outer surface of a ...

second embodiment

[0136]A method for depositing a noble metal on a carbon steel member of a nuclear power plant according to a second embodiment applied to a purification system piping of a boiling water type nuclear power plant, which is another preferred embodiment of the present invention, will be described with reference to FIGS. 9 and 10. The method for suppressing the deposition of radionuclides on a carbon steel member of a nuclear power plant according to the present embodiment is applied to a carbon steel purification system piping (carbon steel member) of the BWR plant.

[0137]In the present embodiment, as shown in FIG. 9, the processes of steps S1 to S3 and S6 to S14 in the method for depositing a noble metal on a carbon steel member of a nuclear power plant according to the first embodiment, and new process of step S4A are performed. The process of step S4A is a process that is performed instead of each of the processes of steps S4 and S5, for injecting an aqueous solution containing a surf...

third embodiment

[0146]A method for suppressing deposition of radionuclides on a carbon steel member of a nuclear power plant according to a third embodiment applied to a purification system piping of a boiling water type nuclear power plant, which is another preferred embodiment of the present invention, will be described with reference to FIG. 11. The method for suppressing the deposition of radionuclides on a carbon steel member of a nuclear power plant according to the present embodiment is applied to a carbon steel purification system piping (carbon steel member) of the BWR plant.

[0147]In the present embodiment, as shown in FIG. 11, the processes of steps S1 to S14 in the method for depositing a noble metal on a carbon steel member of a nuclear power plant according to the first embodiment and new processes of steps S15 to S16 in addition to these processes are performed.

[0148]After the processes of steps S1 to S14 are performed, the processes of steps S15 and S16 are performed. The processes o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com