Electrolytic sn or sn alloy plating solution and method for producing sn or sn alloy plated article

a technology of alloy plating solution and which is applied in the field of electrolysis sn or sn alloy plating solution for forming a plated article, can solve the problems of unreachable problems, etc., and achieve the effects of preventing an influence on device malfunction, lowering pb concentration, and lowering pb concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

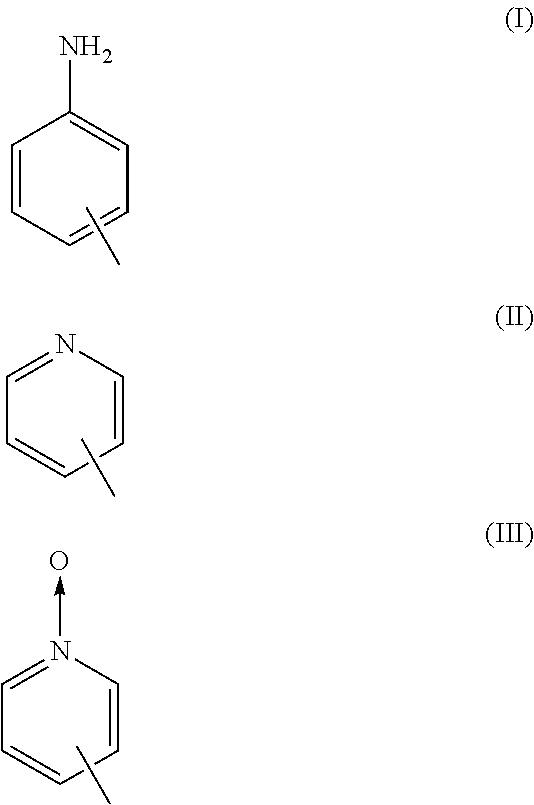

[0085]In an example 1, as an electrolytic Sn plating solution, a sulfur-based compound, an Sn salt, an organic acid, and a surfactant were added. As the sulfur-based compound, 5 g / L of dibenzyl disulfide was added. As the Sn salt, 40 g / L of Sn (II) alkane sulfonate was added as Sn (Sn2+). As the organic acid, 155.3 g / L, of organic sulfonic acid was added. As the surfactant, 5 g / L of polyoxyethylene alkyl phenyl ether was added. In addition, as the crystal regulator, 0.15 g / L of 2-mercapto benzothiazole was added. A solution temperature of the plating solution was 30° C., and a current density was 4 A / dm2. Further, in the example 1, a plating solution using an Sn salt with low Pb concentration of 1.0 ppm or less was also prepared.

[0086]At this time, Pb concentration in raw material metal Sn of the Sn salt was 15.454 ppm, and. Pb concentration in raw material metal Sn of the Sn salt with low Pb concentration was 0.407 ppm.

[0087]And, by using the above two plating solutions, electrolyt...

example 2

[0088]In an example 2, as the sulfur-based compound, 5 with of 4, 4′-dipyridyl disulfide was added. In addition, conditions of the Sn salt, the organic acid, the surfactant, the crystal regulator, the solution temperature, and the current density were same as the example 1.

[0089]At this time, Ph concentration in raw material metal Sn of the Sn salt was 15.454 ppm, and Pb concentration in raw material metal Sn of the Sn salt with low Pb concentration was 0.407 ppm.

[0090]And, by using the above two plating solutions, electrolytic Sn plating was performed respectively, and a eutectic ratio (%) of Pb, a eutectic amount of Pb, and a deposition potential were measured.

example 3

[0091]In an example 3, as the sulfur-based compound, 5 g / L of diphenyl disulfide was added. In addition, conditions of the Sn salt, the organic acid, the surfactant, the crystal regulator, the solution temperature, and the current density were same as the example 1.

[0092]At this time, Ph concentration in raw material metal Sn of the Sn salt was 15.454 ppm, and Pb concentration in raw material metal Sn of the Sn salt with low Pb concentration was 0.407 ppm.

[0093]And, by using the above two plating solutions, electrolytic Sn plating was performed respectively, and a eutectic ratio (%) of Pb, a eutectic amount of Pb, and a deposition potential were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water-soluble | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com