Meat patty tray and method of packaging and display

a technology applied in the field of meat patty tray and packaging method, and trays for packaging frozen or thawed food products, can solve the problems of affecting the aesthetic appeal the plastic film of the underlying trays being stretched and loosened during shipment, and the contamination of adjacent packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

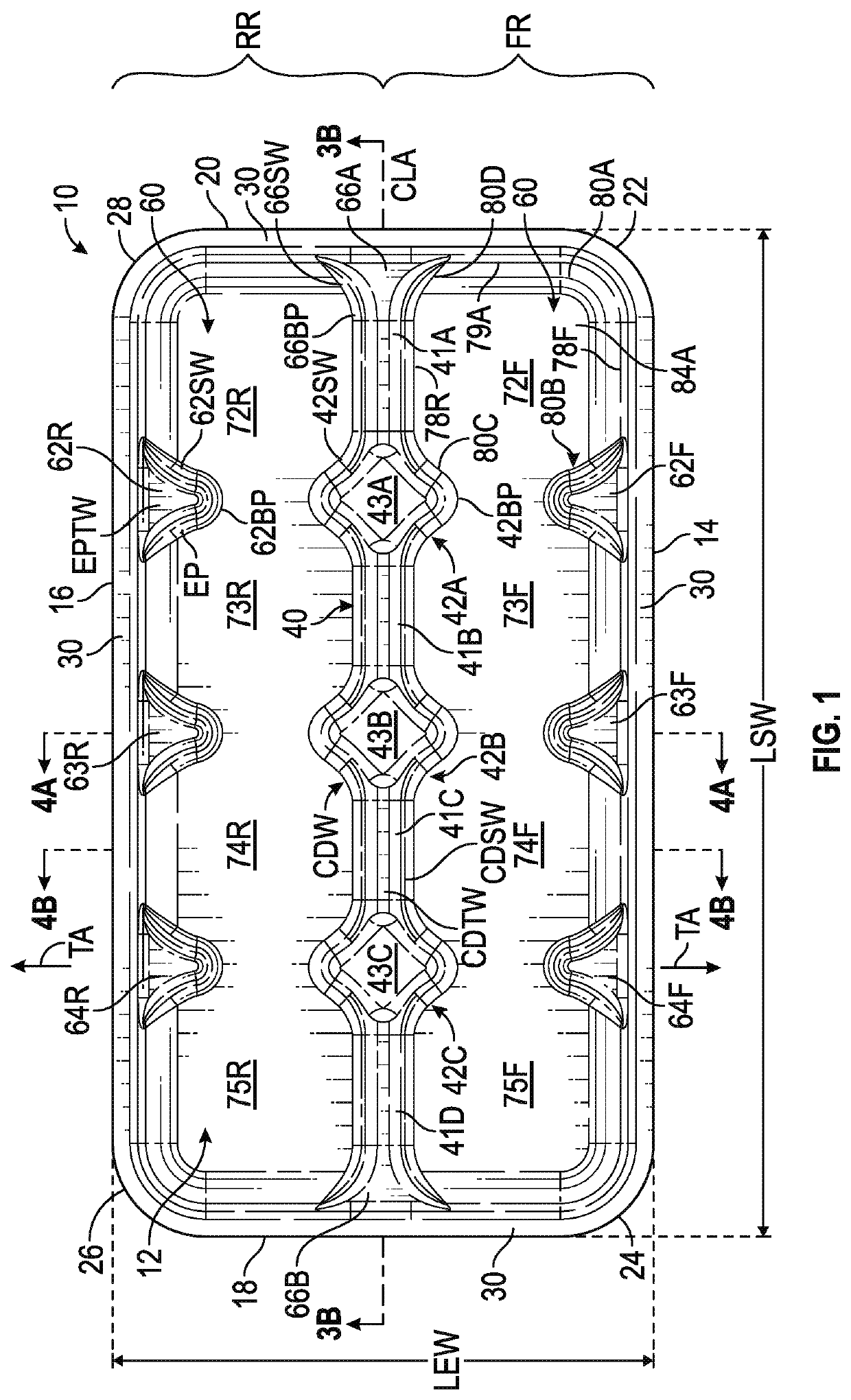

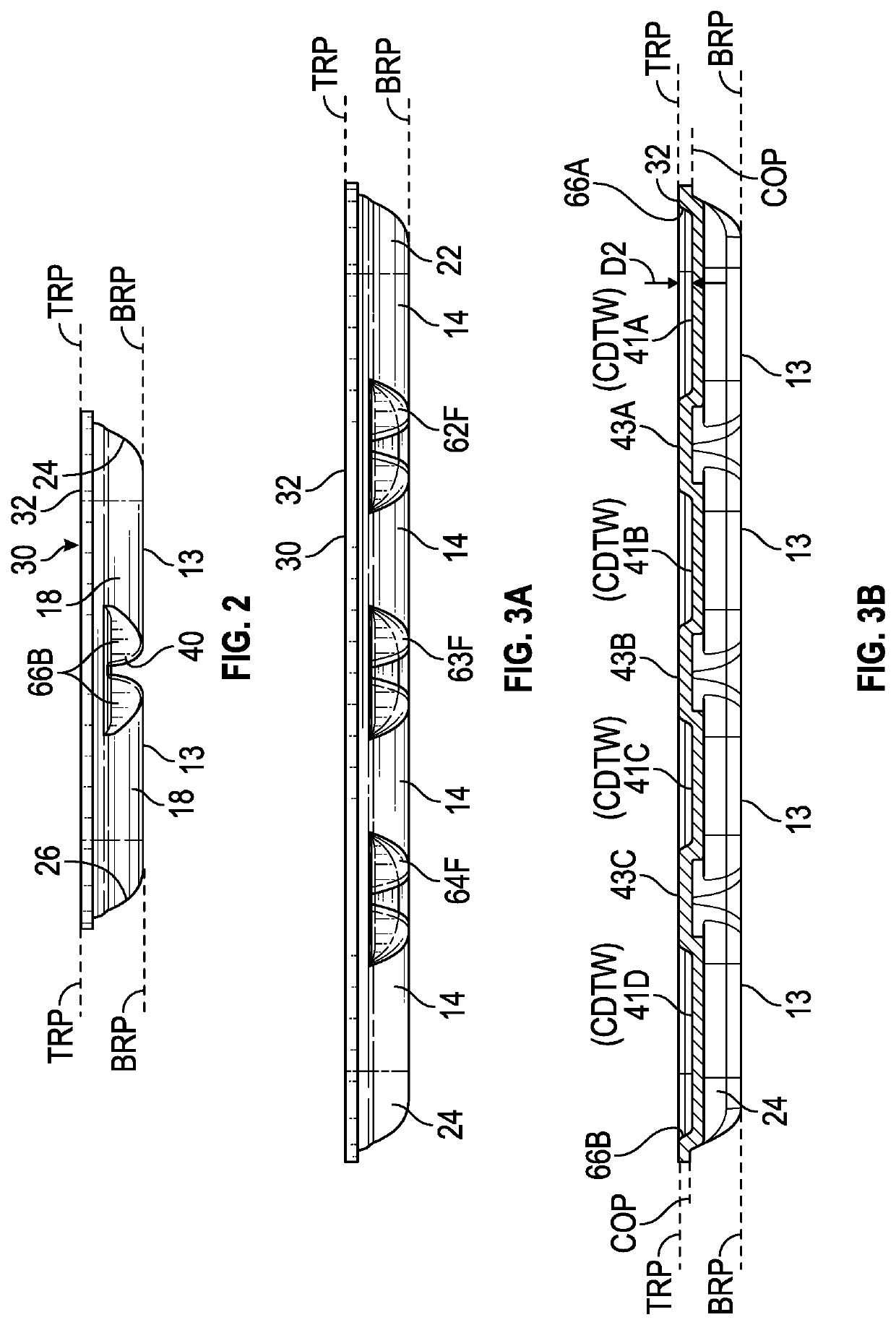

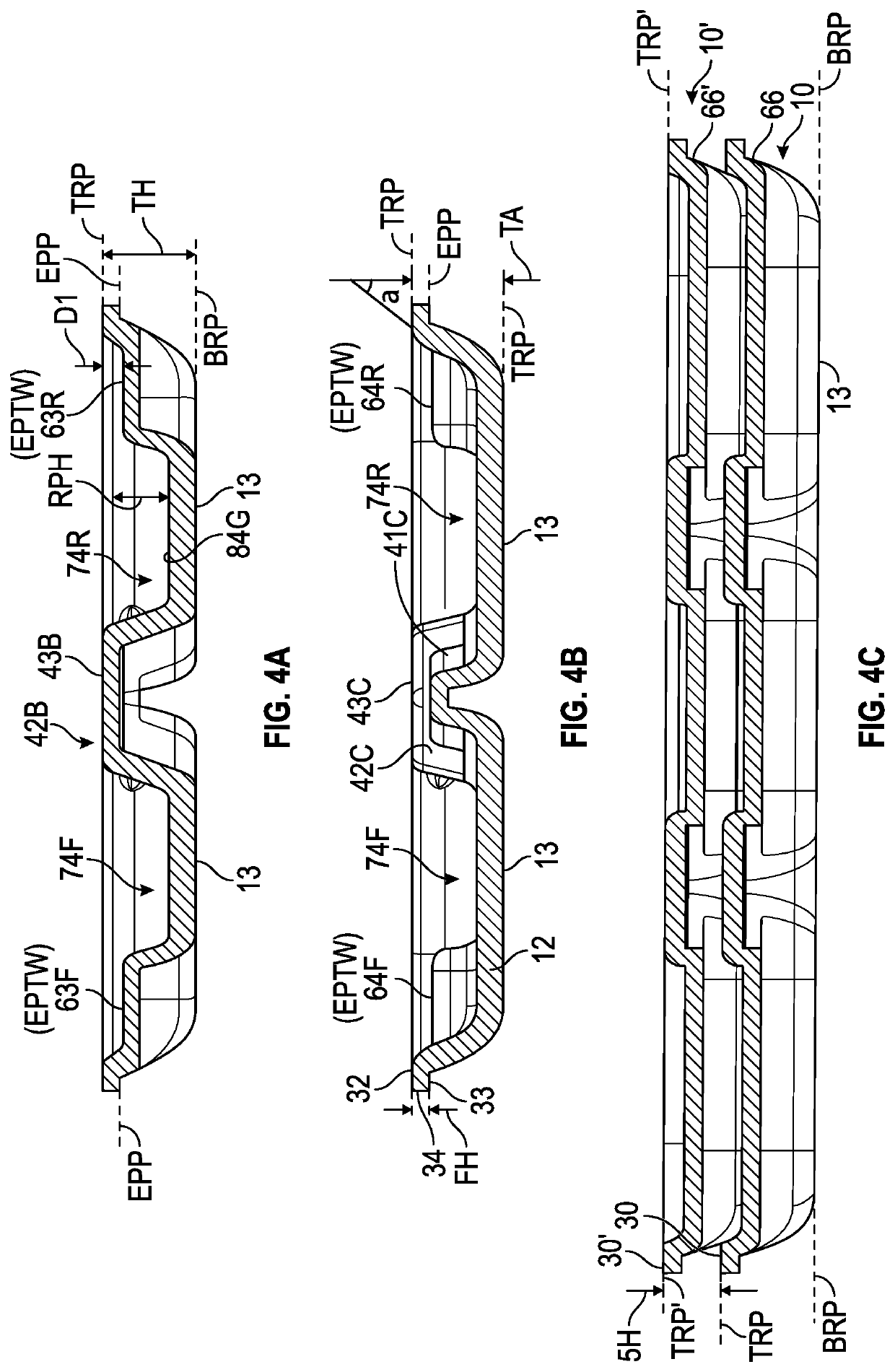

[0083]Referring generally to FIGS. 1-10, a tray of the invention is depicted therein and generally designated with the numeral 10, including a central divider wall CDW 40 having three central posts 42A-C. FIGS. 1-6 show the empty (unloaded and unwrapped) tray 10. FIG. 7 shows the same tray 10 loaded with eight disc shaped meat products P1-8, here sausage patties. FIGS. 8A-9 show the loaded tray 10 with a clear plastic film wrap F surrounding the tray and patties, and FIG. 10 shows a plurality of such loaded and wrapped trays each inclined on its front side edge 14 and aligned in a row for display (e.g. in an open ended refrigerated storage case at a grocer / retailer).

[0084]The tray 10 may be formed of various plastic materials, foam or non-foam, including polystyrene PS, polypropylene PP, and polyester (e.g., polyethylene terephthalate PET). In one embodiment the tray is formed of a plastic foam material, such as polystyrene foam, for light weight, ease of manufacture and low cost. T...

second embodiment

[0107]FIGS. 11-20 illustrate a second embodiment, in which like elements are labeled with like reference numbers, utilizing a “100” number series (i.e., tray 10 in FIGS. 1-10 is tray 110 in FIGS. 11-20). The views are substantially the same, as outlined above in the Brief Description of the Drawings, with differences noted therein.

[0108]In the second embodiment, tray 110, is substantially the same as the first embodiment tray 10, with the following differences:

[0109]a) a transverse groove TG is provided in each center post 142 and end post 166, to provide increased structural rigidity to the tray and e.g., to prevent the tray from folding inwardly along the CLA; the groove TG is vertically recessed from the TRP and extends a distance TGH from the TRP (see FIGS. 3B and 3C);

[0110]b) the wall portions 141 joining the center posts to the end posts lie in the TRP.

[0111]Variations may be provided in the materials, dimensions and features similar to the first embodiment as described above....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com