Packaging tray

a packaging tray and tray body technology, applied in the field of packaging tray, can solve the problems of affecting the quality of fresh food products, irregularly filled trays, and inability to meet the needs of consumers, and achieve the effects of facilitating the de-nesting of empty stacks, and facilitating the movement of wrapped packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

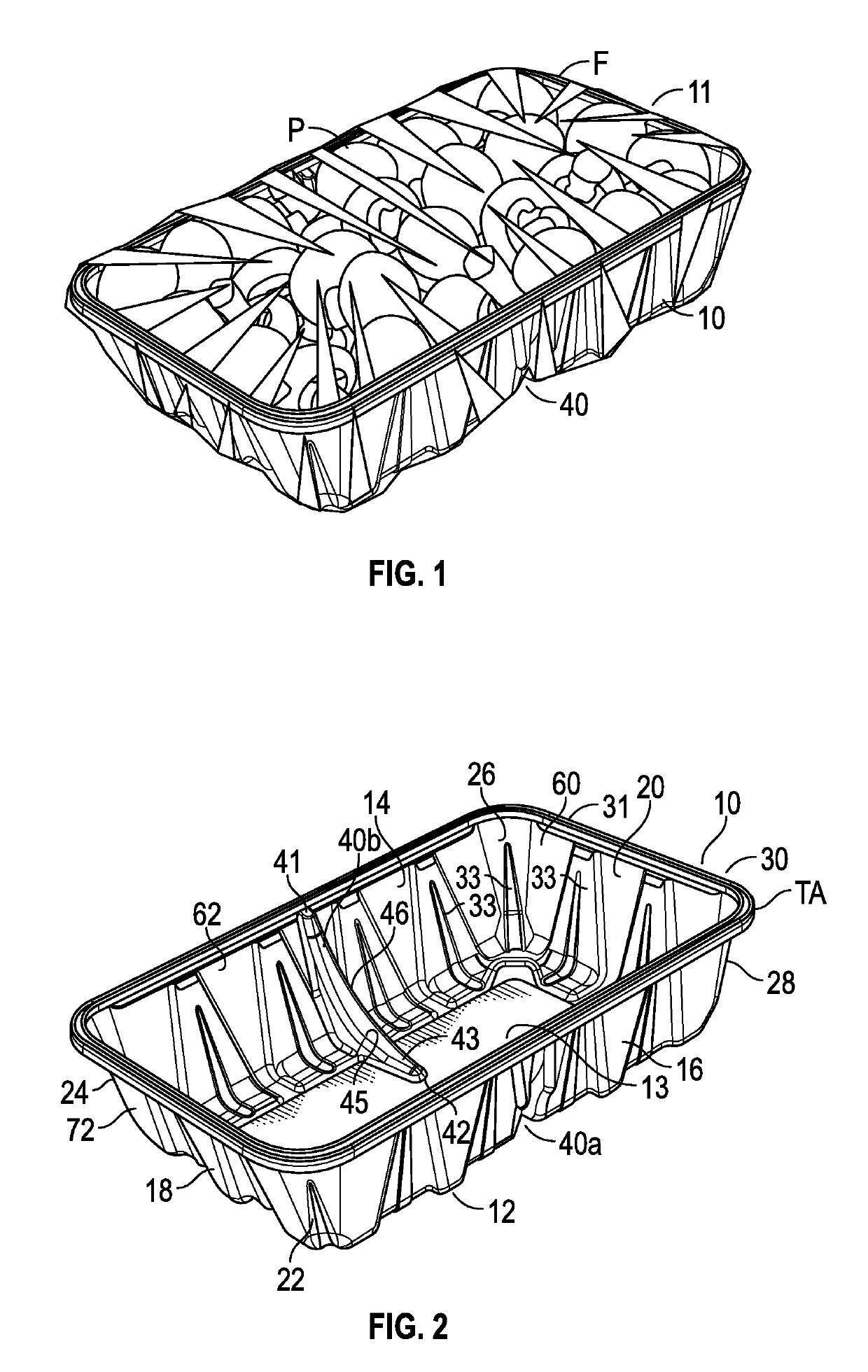

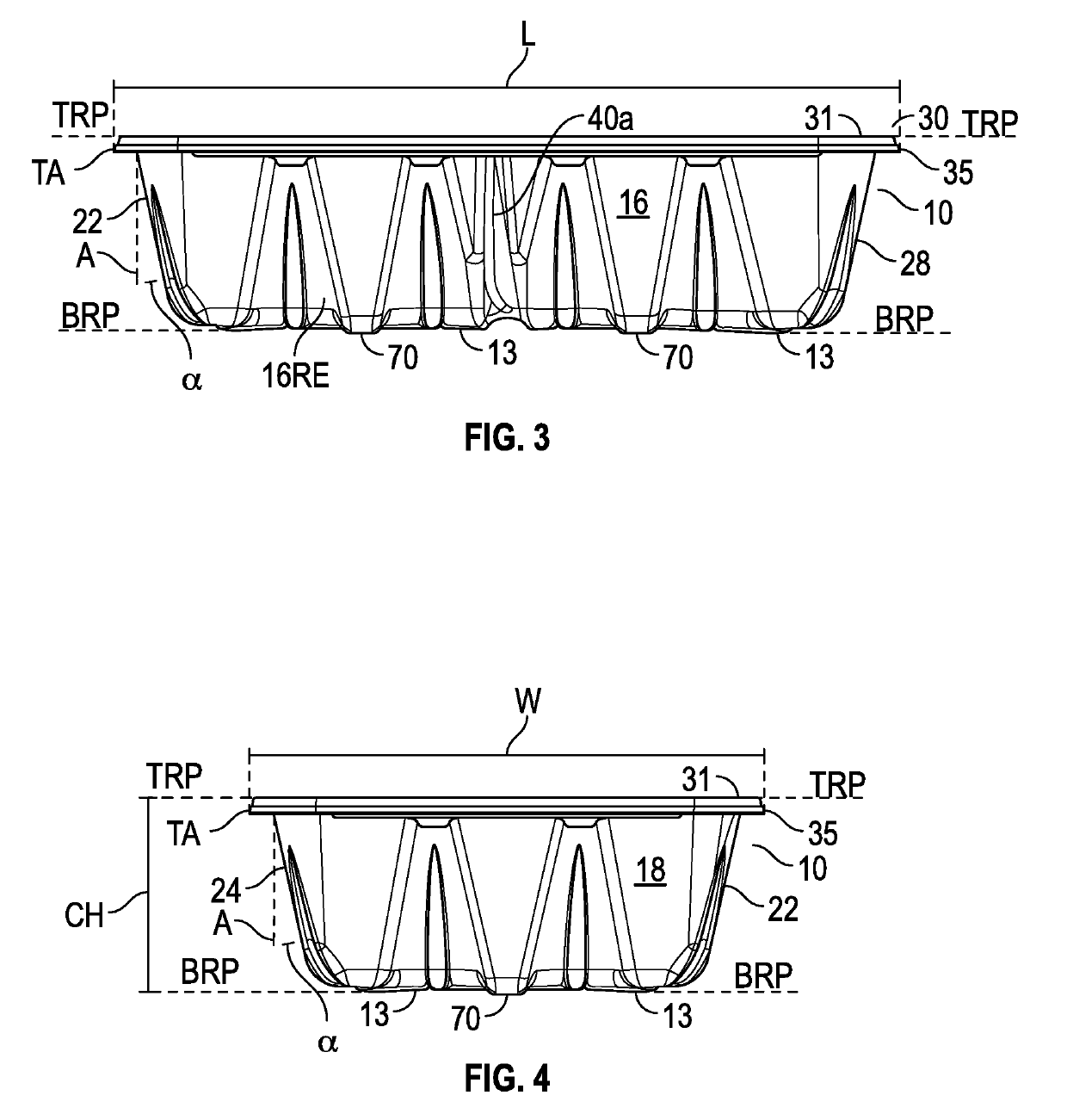

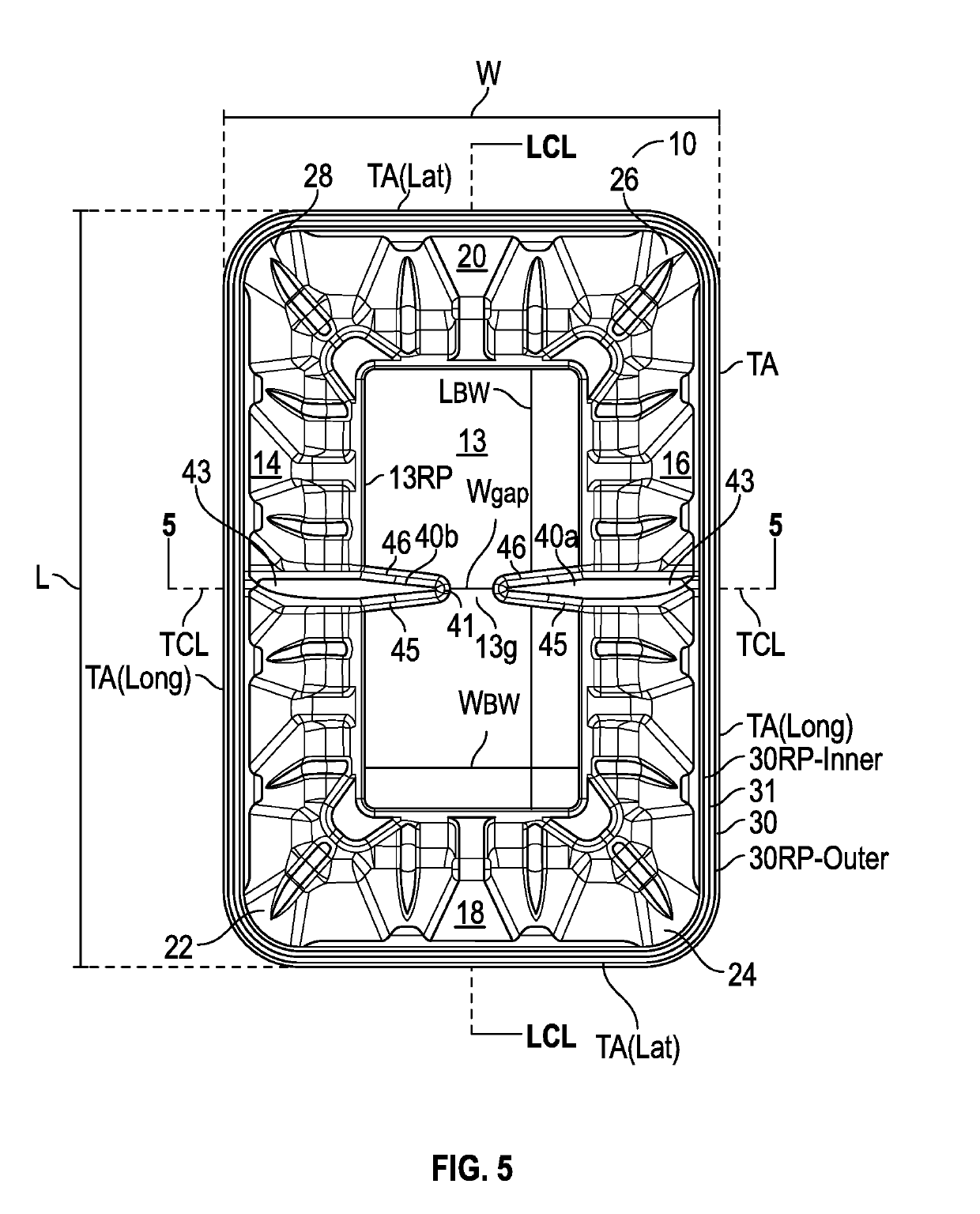

[0045]Referring generally to FIGS. 1-8, a first embodiment of a plastic tray of the invention is depicted therein and generally designated with the numeral 10. FIG. 1 shows the tray 10 filled with a product P, here a predetermined amount (e.g., by weight or volume) of fresh whole mushrooms, which is then wrapped with a clear plastic film F (overwrap) to contain, preserve and display the product within the wrapped package 11. FIGS. 2-8 show the empty tray 10, prior to filling and wrapping, providing interior and exterior views of the tray having a pair of opposing central ribbing elements 40a, 40b according to one embodiment of the invention. The tray with central ribbing elements provides a desired combination of strength and rigidity in a light weight molded plastic tray that is easy to manufacture, fill, handle and wrap. These advantages will be described further below.

[0046]In forming the tray 10 it is preferred that the tray be unitarily formed from a single sheet of plastic mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com