Hybrid yarns formed with fibers having rounded tips and method of making the same

a technology of yarn and fiber, applied in the field of hybrid yarns, can solve the problems of difficult to provide all desired fabric characteristics with a single yarn formed with a single natural or synthetic material, difficult to meet the requirements of the customer, etc., to achieve the effect of reducing transportation management or regulation, not deteriorating the performance of the technology, and accelerating drying tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

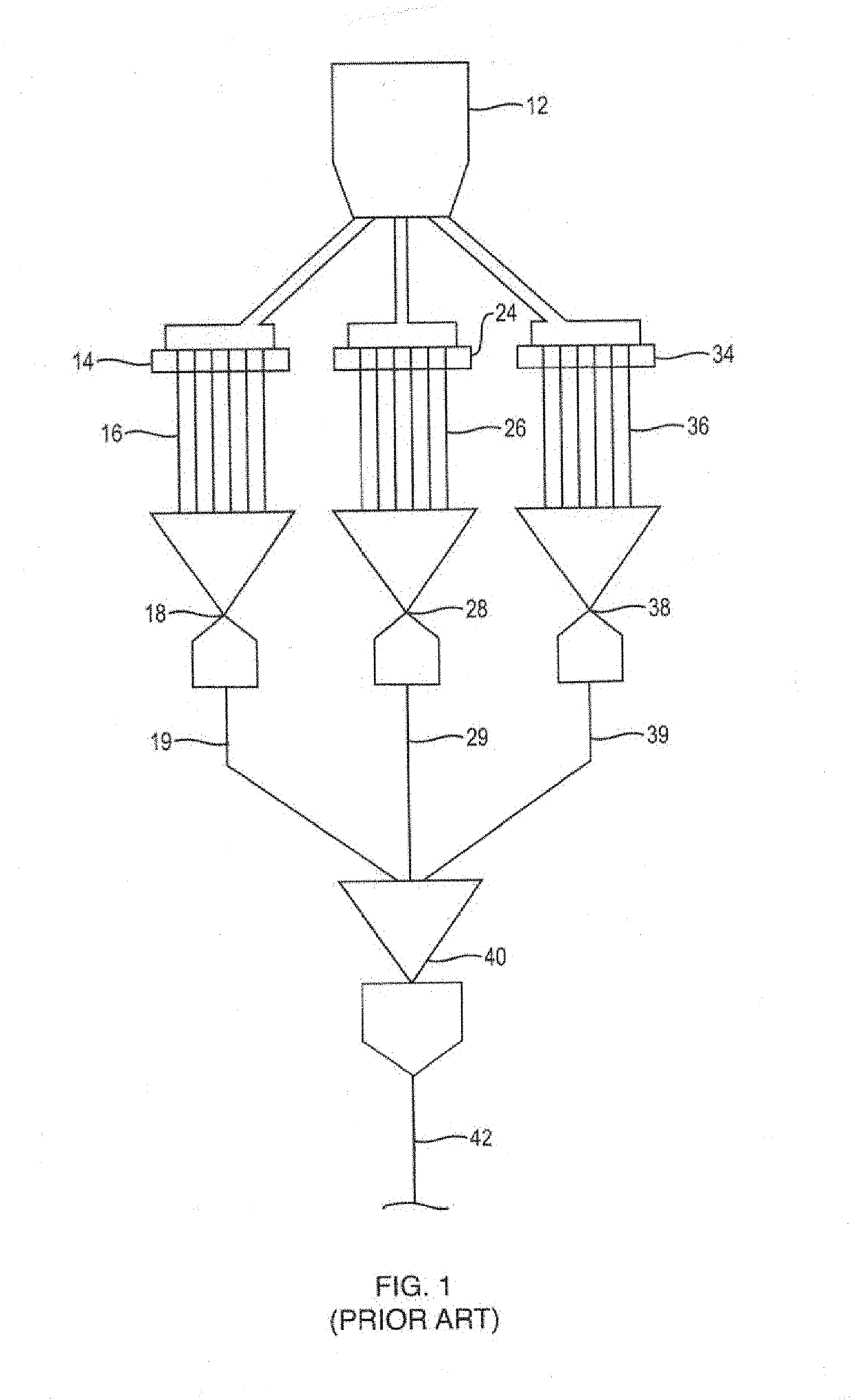

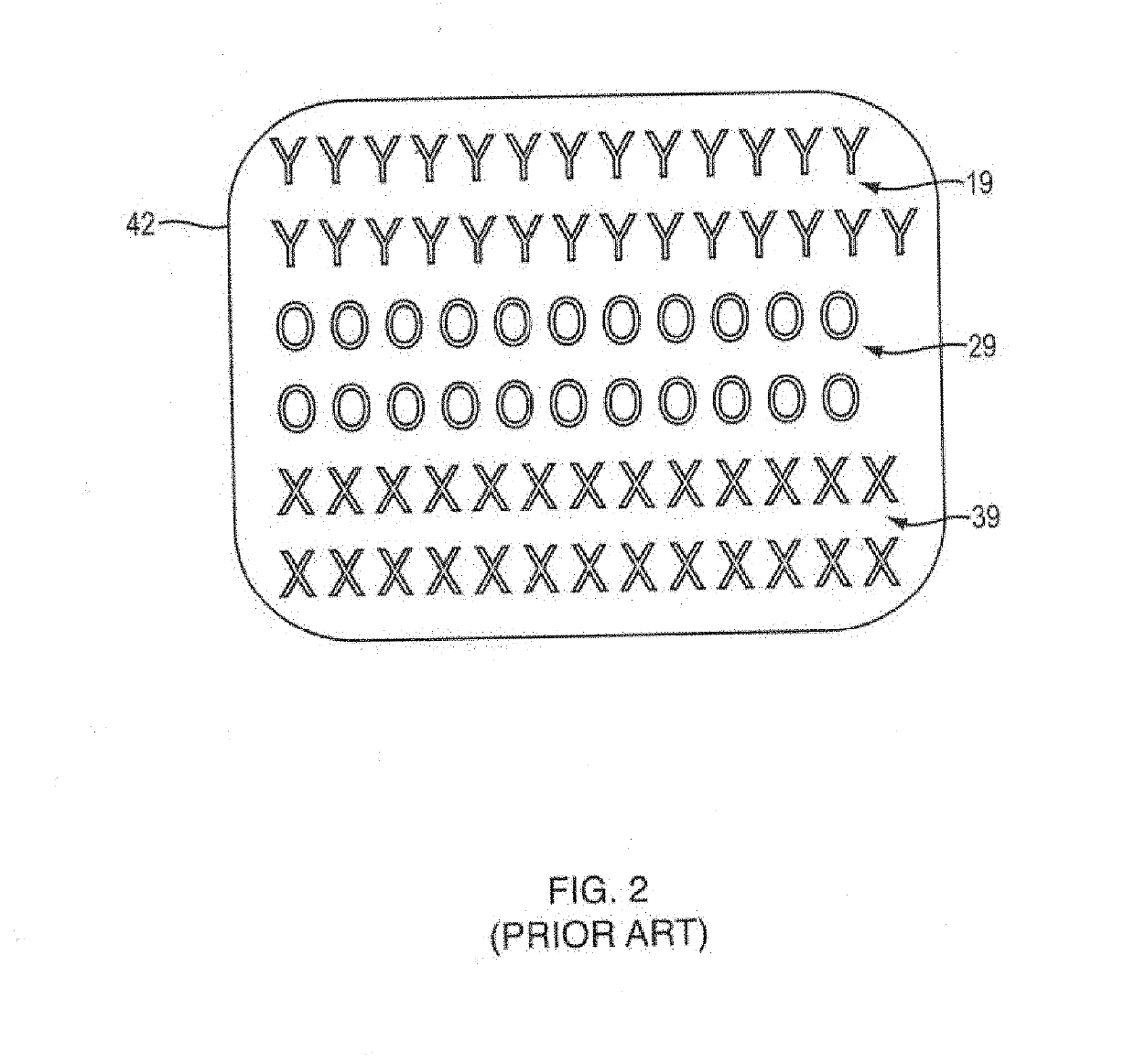

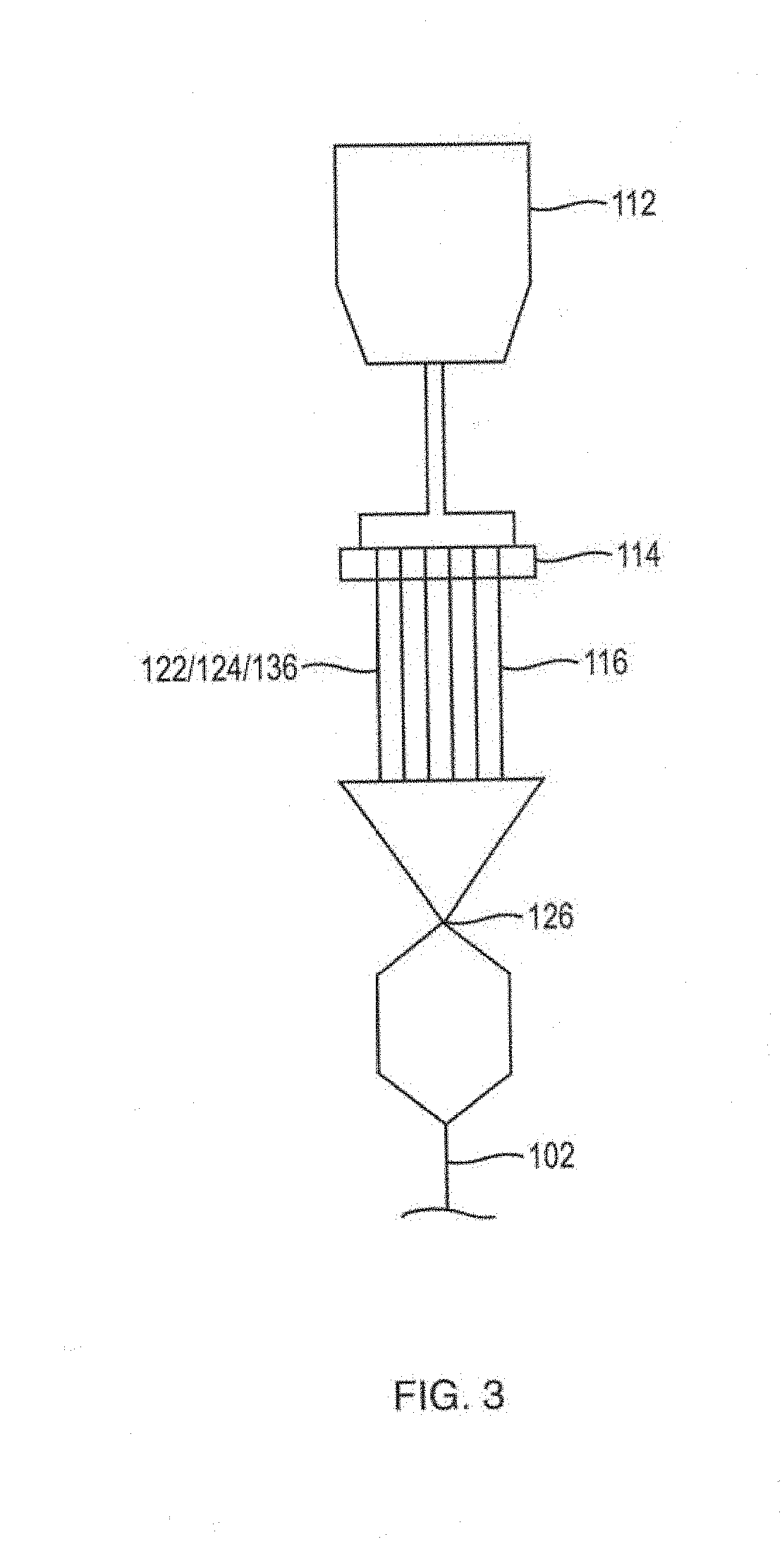

[0033]A hybrid yarn of the present invention includes a plurality of fibers with the plurality of fibers including a plurality of different fiber compositions wherein there may be three or more different fiber compositions. The different fiber compositions may be three or more different fiber cross sections formed of the same material such as a synthetic material. The different fiber compositions may be different filament materials. The different fiber compositions may be a combination of different materials and different cross sections. The plurality of fibers are combined together in a texturing process so that the fibers of different compositions are interspersed among themselves so that they are integrated with one another in a selectable yarn construction. Those fibers having tips are made so that the tips are rounded.

[0034]The hybrid yarn including the three or more different fiber cross sections can be made with a single synthetic material such as a polymeric material such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shapes | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com