Polymer blend for cable jackets

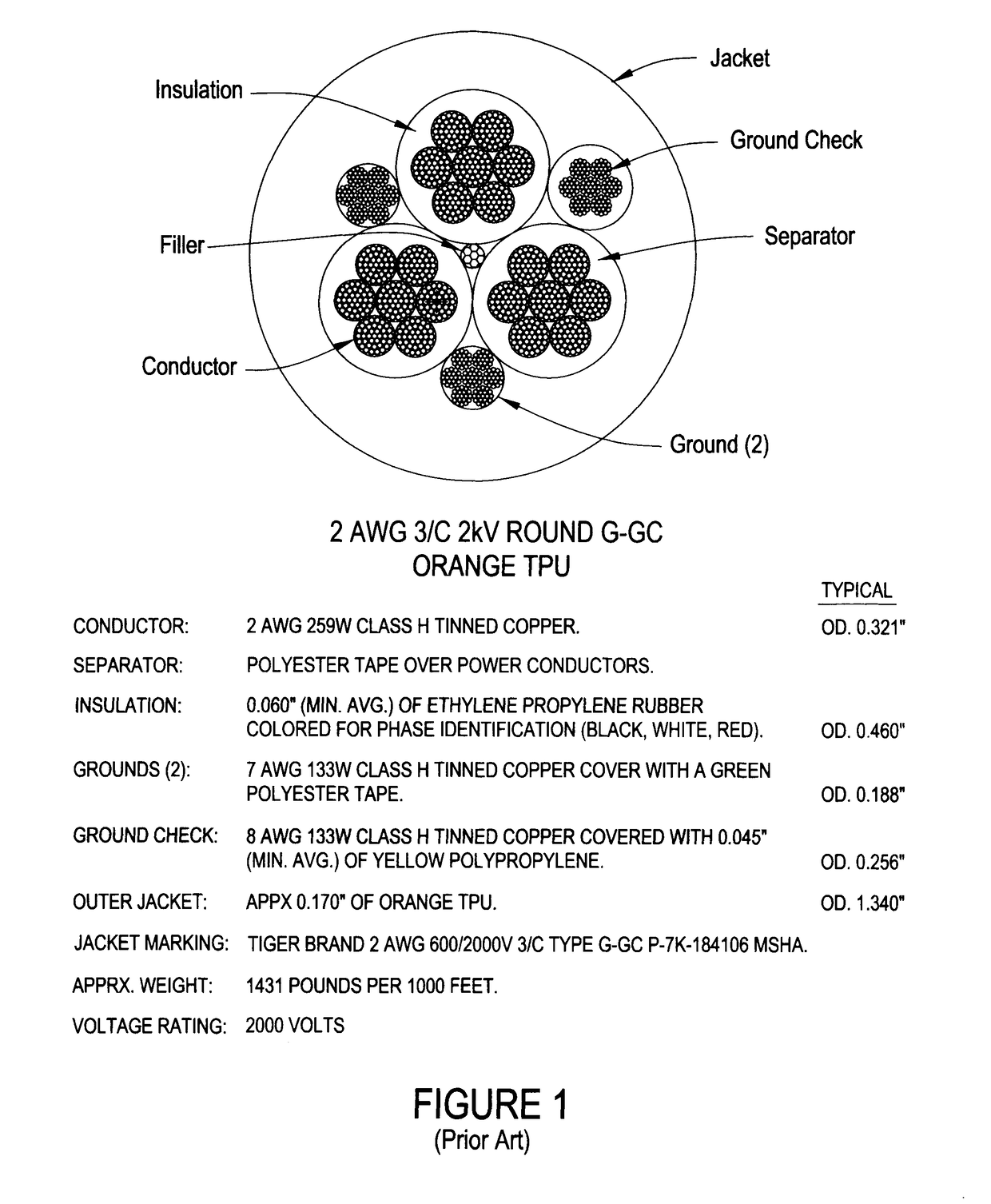

a technology of polymer blend and cable jacket, which is applied in the direction of insulated conductors, cables, cables, etc., can solve the problems of high cost of tpu polymer, failure of primary outer insulation jackets, and high environmental conditions of heavy equipment cables, so as to reduce the amount of tpu used, the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

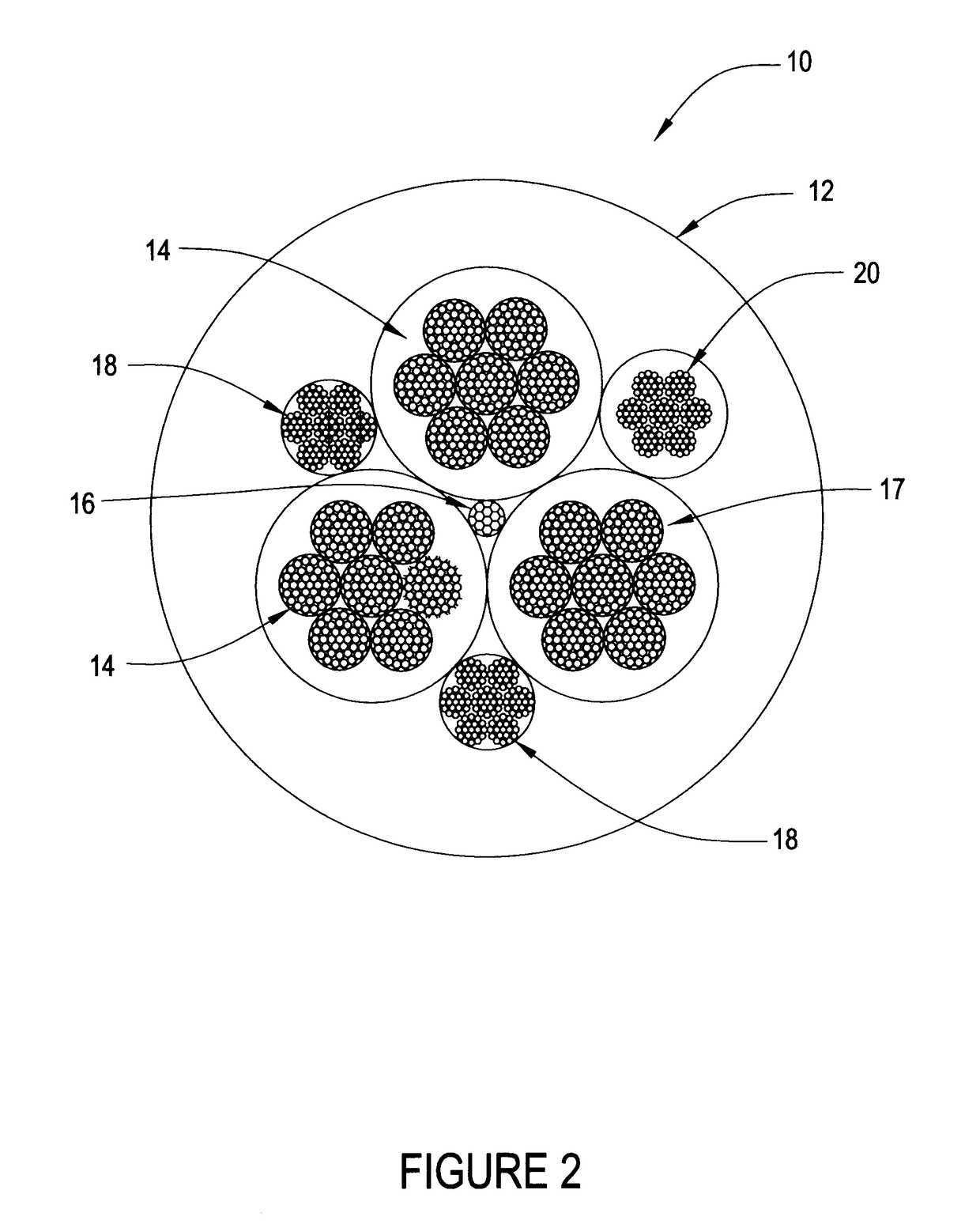

[0015]The present arrangement as shown in FIG. 2 illustrates an exemplary cable 10 that is used in the mining industry. Among other elements, cable 10 has an outer jacket 12, insulated conductors 14, a filler 16, ground wires 18 and a ground check wire 20.

[0016]In one example insulated conductors 14 are constructed as three separate 2AWG (American Wire Gauge) tinned copper conductors insulated with ethylene propylene rubber. Filler 16 is positioned in the center of cable 10 to maintain the spacing of conductors 14. Ground wires 18 may be constructed of 7AWG tinned copper covered in polyester tape. Ground check 20 may be constructed with 8AWG tinned copper and insulted with polypropylene.

[0017]Applicants note that cable 10 is an exemplary construction of the type of cables, such as a mining cable that the present TPU / PVB polymer blend may be applied as a jacket. However, the salient features of the present arrangement, and in particular the polymer blend used for jacket 12, may be us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com