Artisan Ice System, Method and Apparatus

a technology of artisan ice and ice, which is applied in the field of artisan ice system, method and apparatus, can solve the problems of unresolved commercial production problem of artisan ice, inflexible conventional clear ice production system as to the size or shape of clear ice produced, and longer life, so as to achieve the highest rate of freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

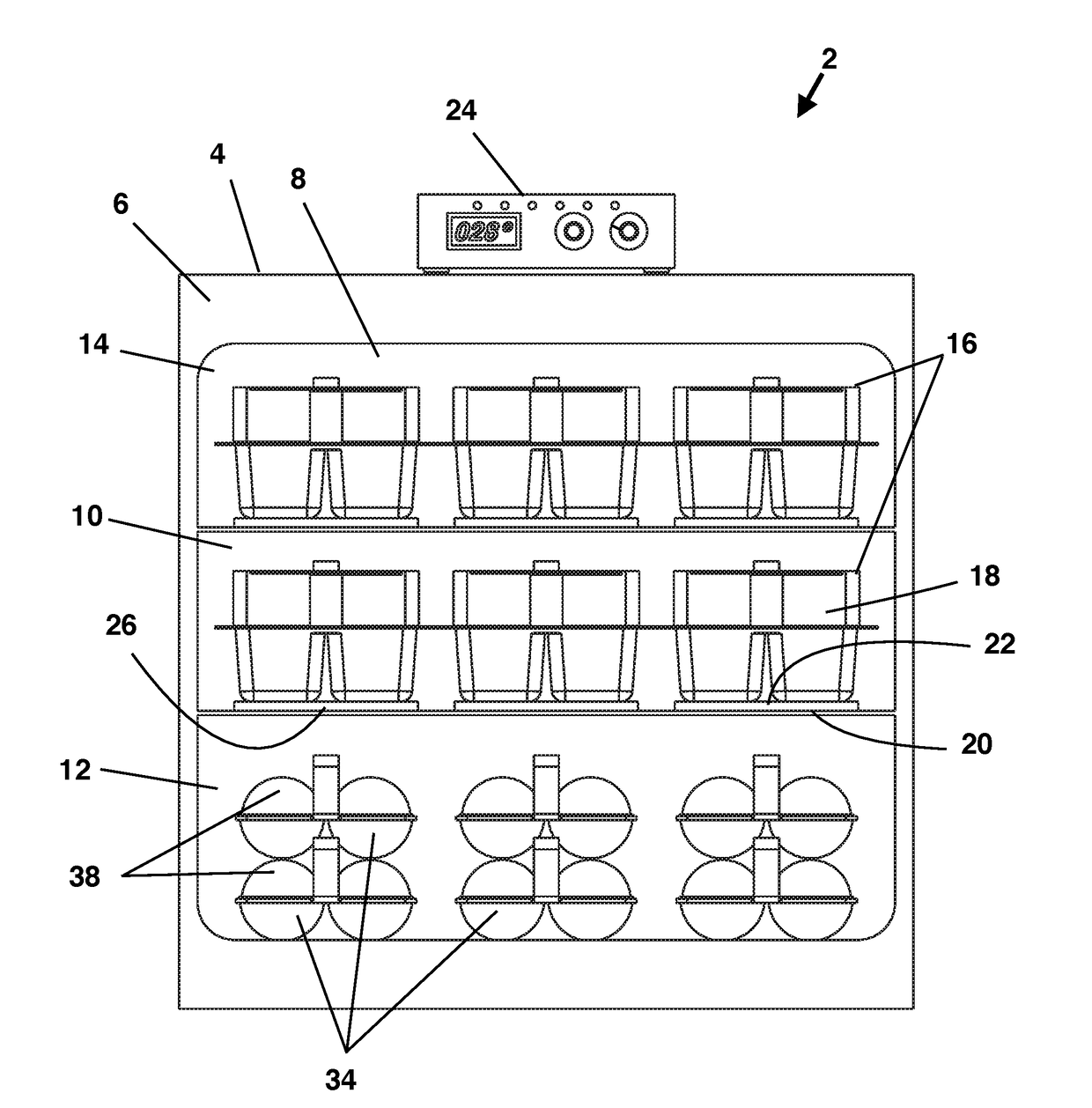

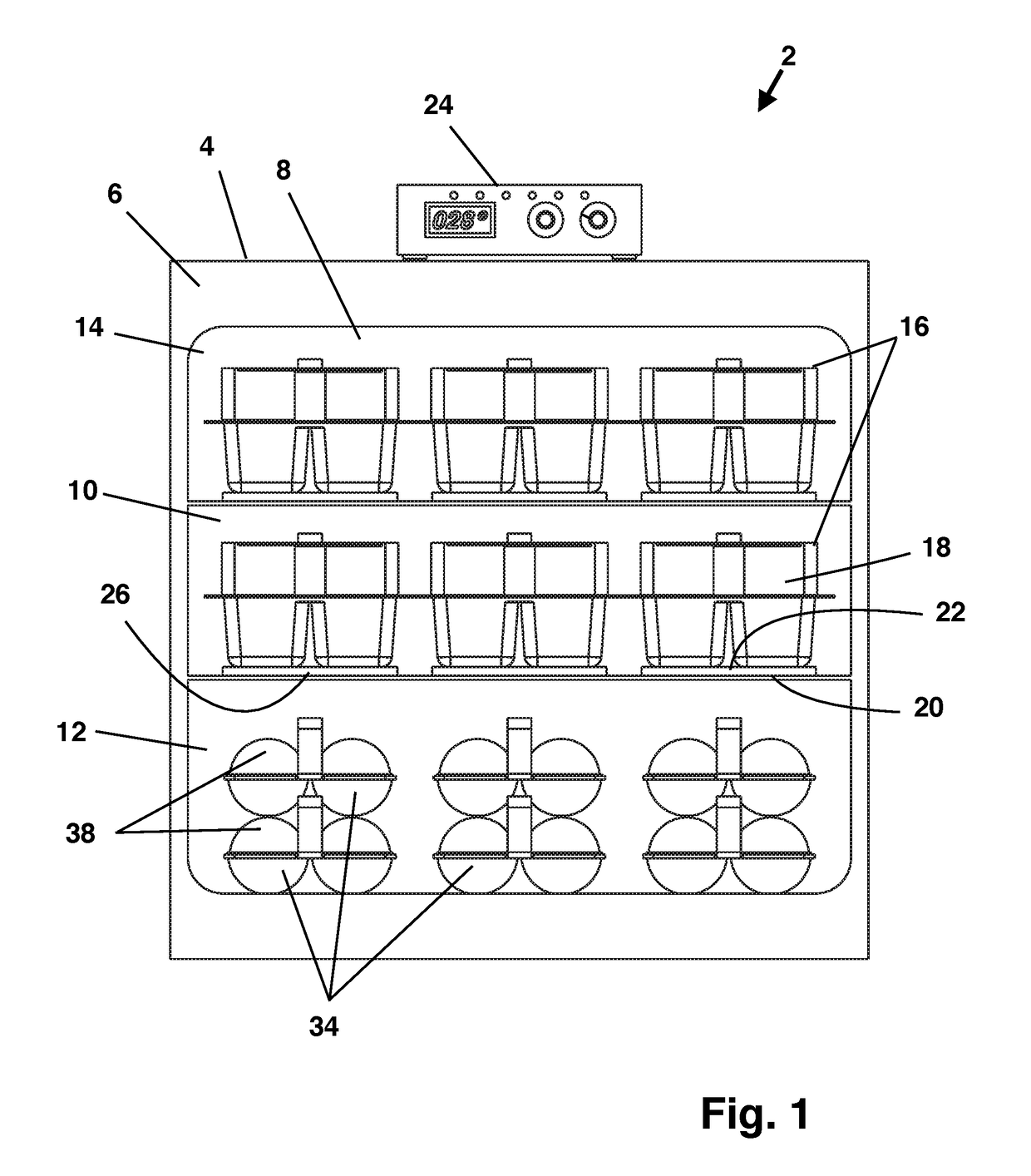

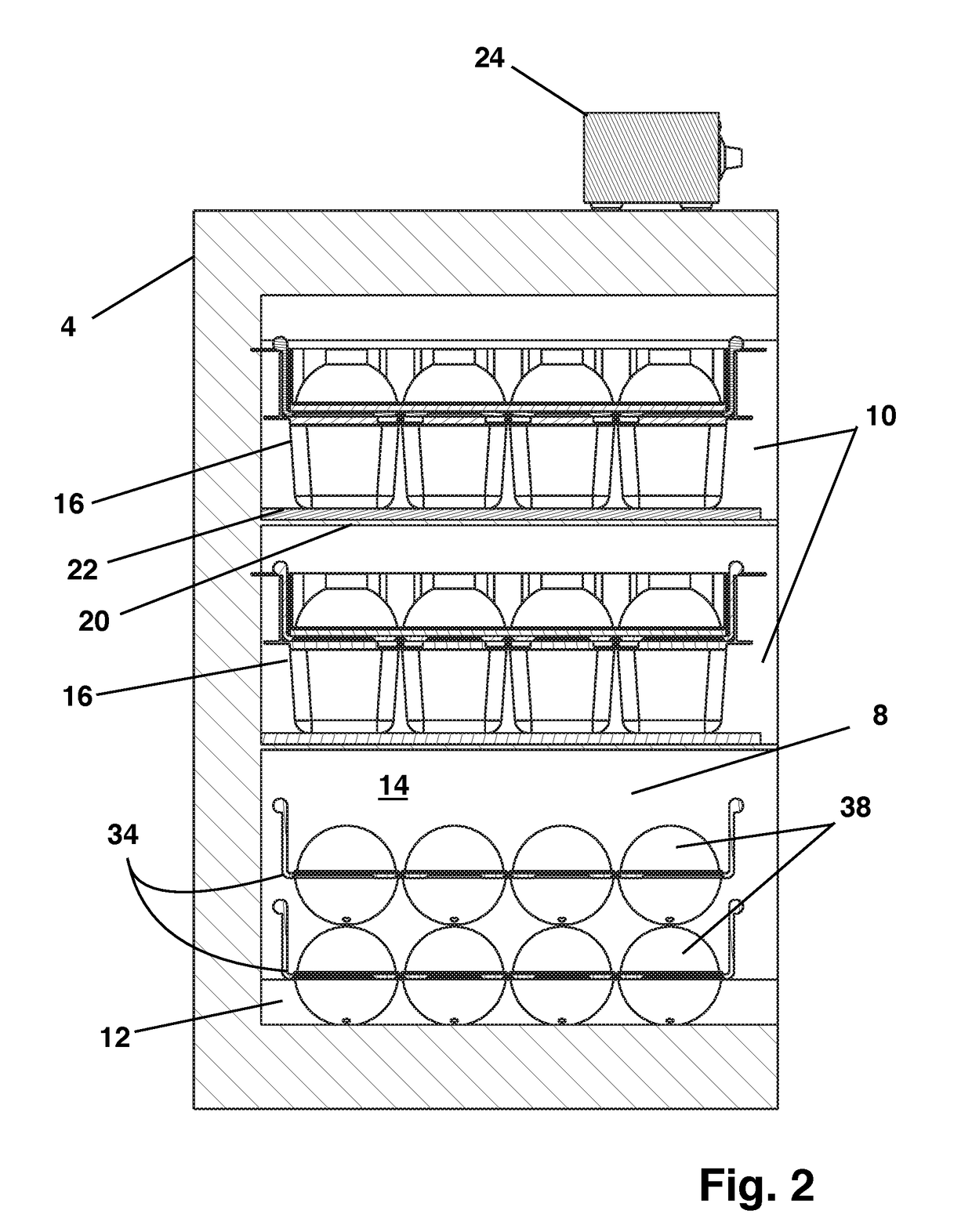

[0033]The artisan ice production system 2 includes a freezer 4, shown by FIGS. 1, 2 and 3. FIG. 1 is a front view of the freezer 4. FIG. 2 is a side sectional view of the freezer 4. FIG. 3 is a perspective of the outside of the freezer 4.

[0034]From FIGS. 1, 2 and 3, the freezer 4 includes insulated walls 6 and a door (not shown) to define a closed interior 8 of the freezer 4. The freezer 4 defines an ice production portion 10 and an ice storage portion 12. The ice production and storage portions 10, 12 may be one and the same. Air 14 on the interior 8 of the freezer 4 is chilled conventionally to below the freezing temperature of water.

[0035]Artisan ice production units 16 are filled with water 18. A user slides he artisan ice production unit 16 into the ice production portion 10 of the freezer 4, as shown by FIGS. 1 and 2. The artisan ice production unit 16 is supported within the freezer 4 by a surface 20, which may be a shelf. The surface 20 includes a heat source 22. Sensors 26 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| freezing temperature | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com