System and methods for fabricating actuators and electrically actuated hydraulic solid materials

a hydraulic solid material and actuator technology, applied in the field of actuators, can solve the problems of adding geometric complexity to traditional methods, 3d printing also offers added geometric complexity, etc., and achieves the effects of stable actuation, easy to achieve voltage and current, and high force strok

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

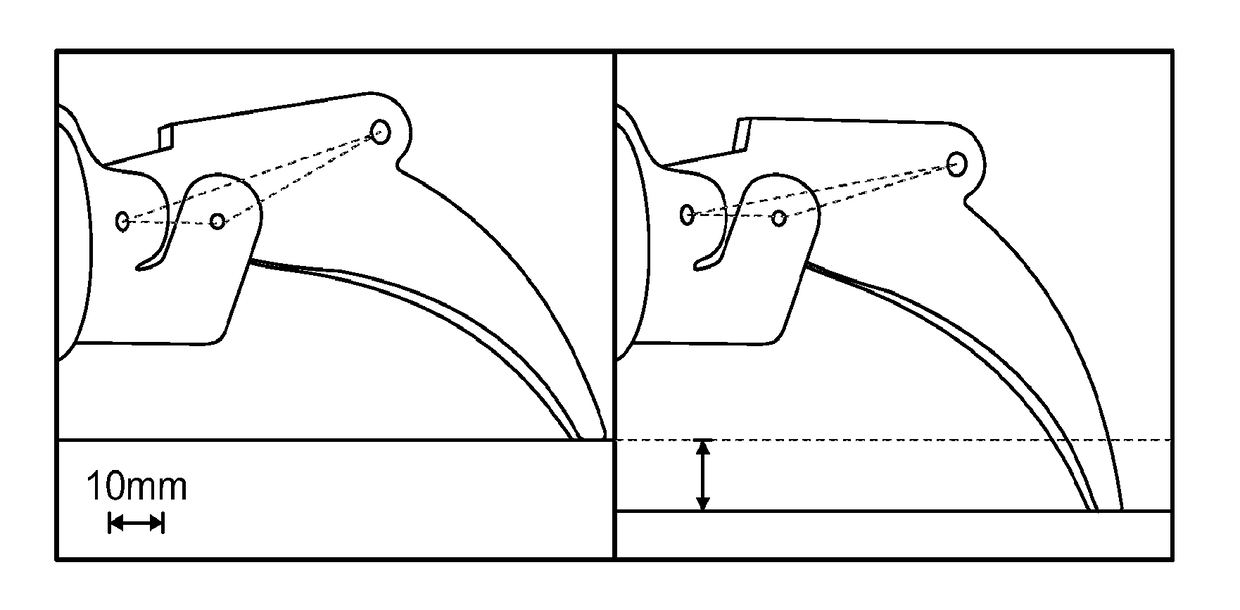

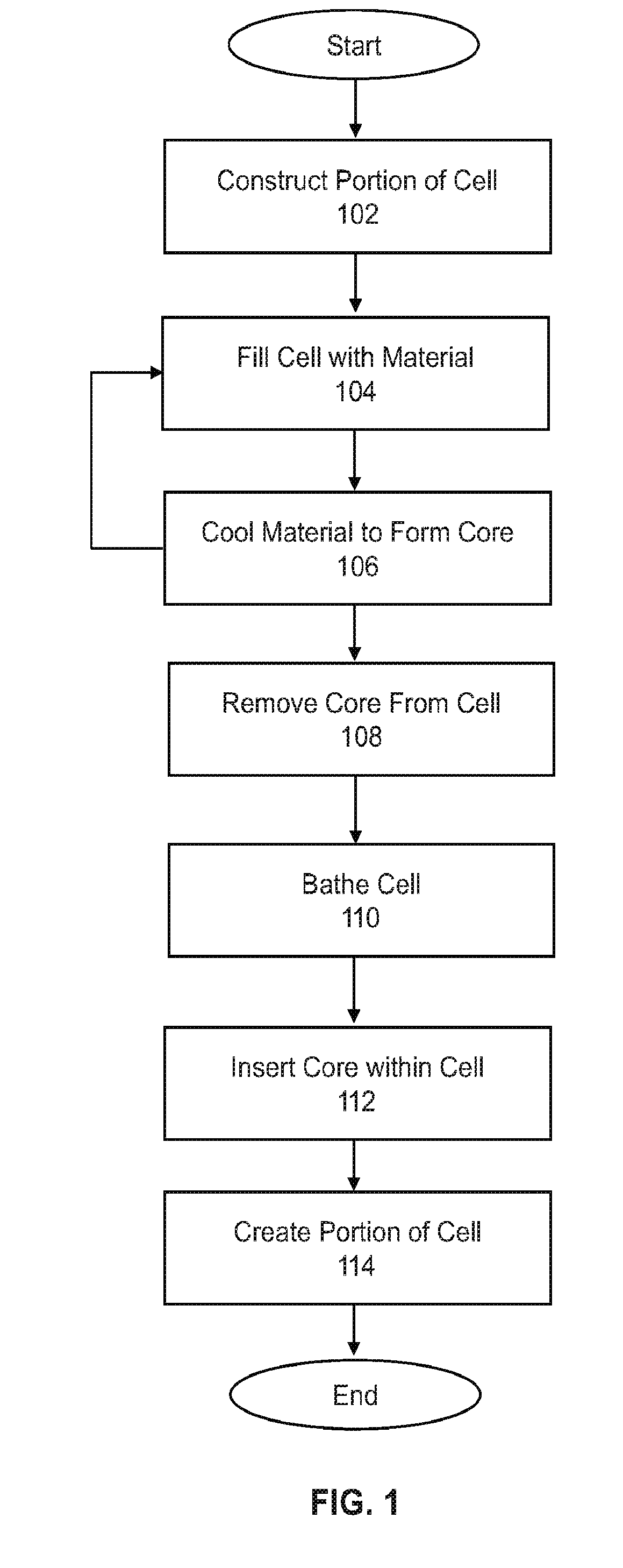

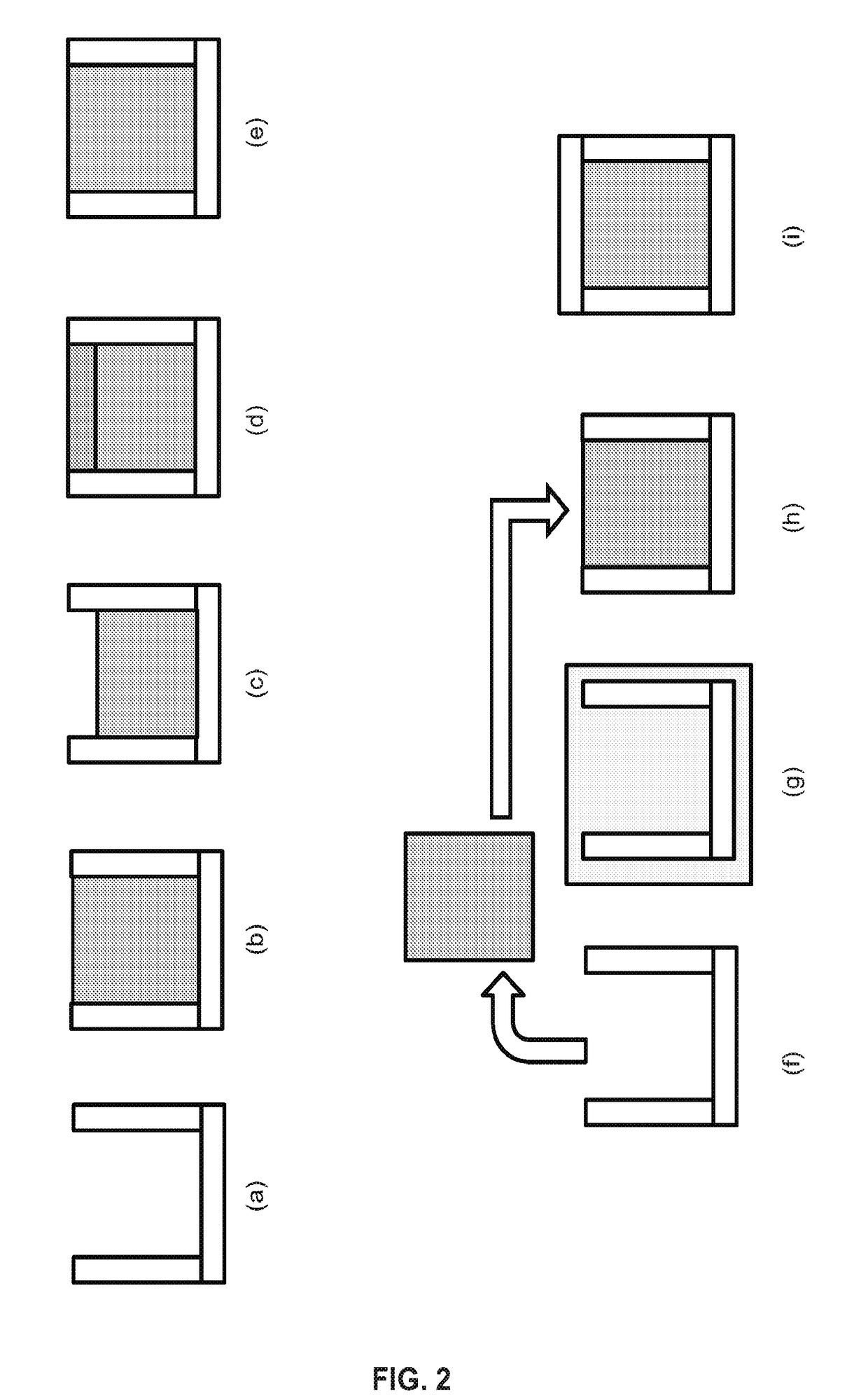

[0042]According to one embodiment, the invention is directed to an actuator fabricated using Solid Freeform Fabrication (SFF). More specifically, the invention is drawn to direct fabrication methods and new materials for fabrication including 3D fabrication. For exemplary purposes, the invention refers to silicone / wax cell actuators when discussing direct fabrication methods and Electrically Actuated Hydraulic Solid (EAHS) actuators when discussing new materials for fabrication of electrically actuated actuators. Similar to traditional actuators, both are complexly soft, allowing them to be integrated into the growing field of soft robotics. Both types of actuators are completely metal free, allowing them to operate in environments like MRIs, where traditional wax actuators would be unable to operate due to their metal housings and pistons. In addition, the actuators of the invention volumetrically expand, which may prove ideal for certain evolutionary biology work. It is also conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| force | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com