System, method and process for disinfection of internal surfaces in aseptic tanks and pipelines by flooding with sanitizing fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

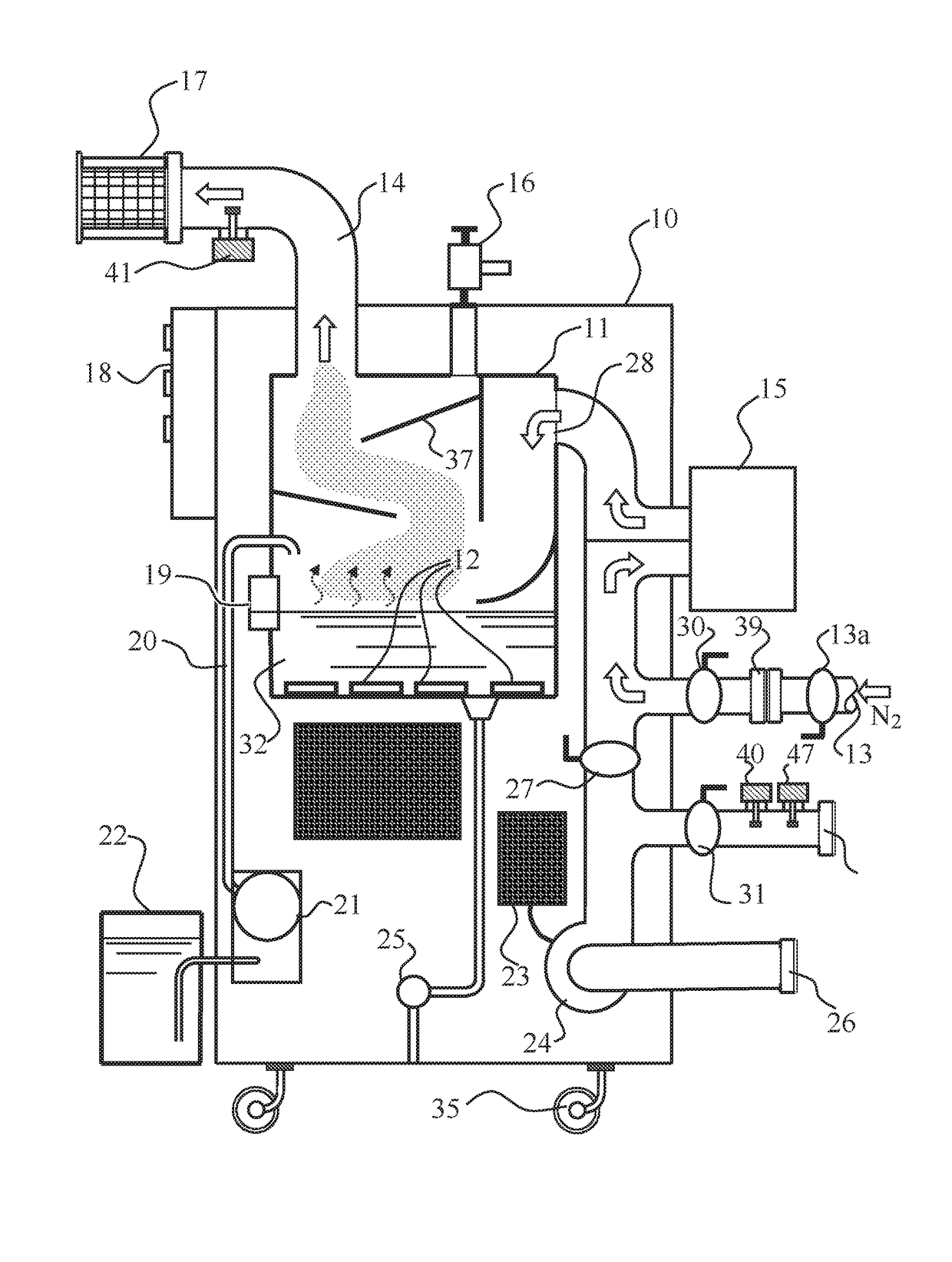

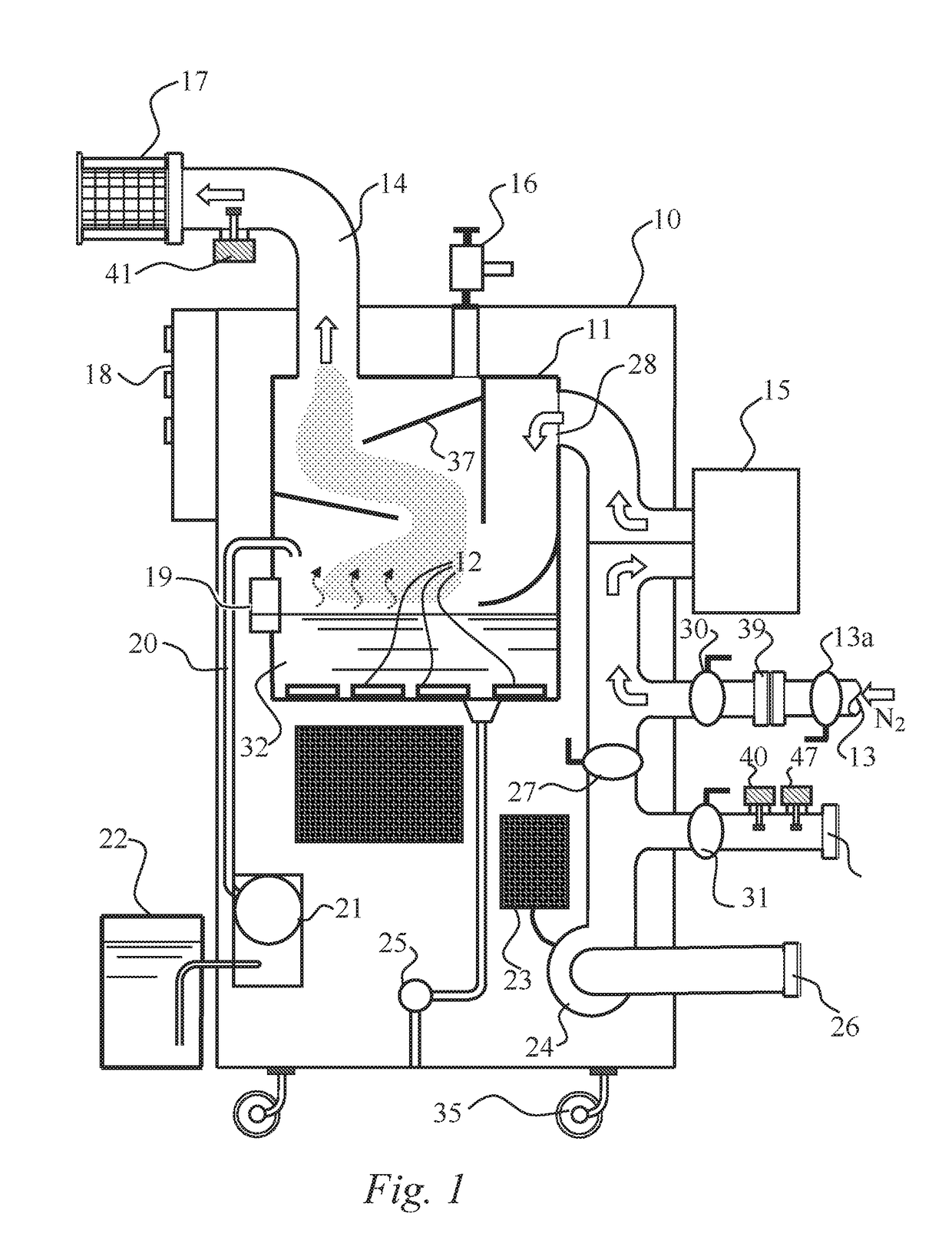

Embodiment Construction

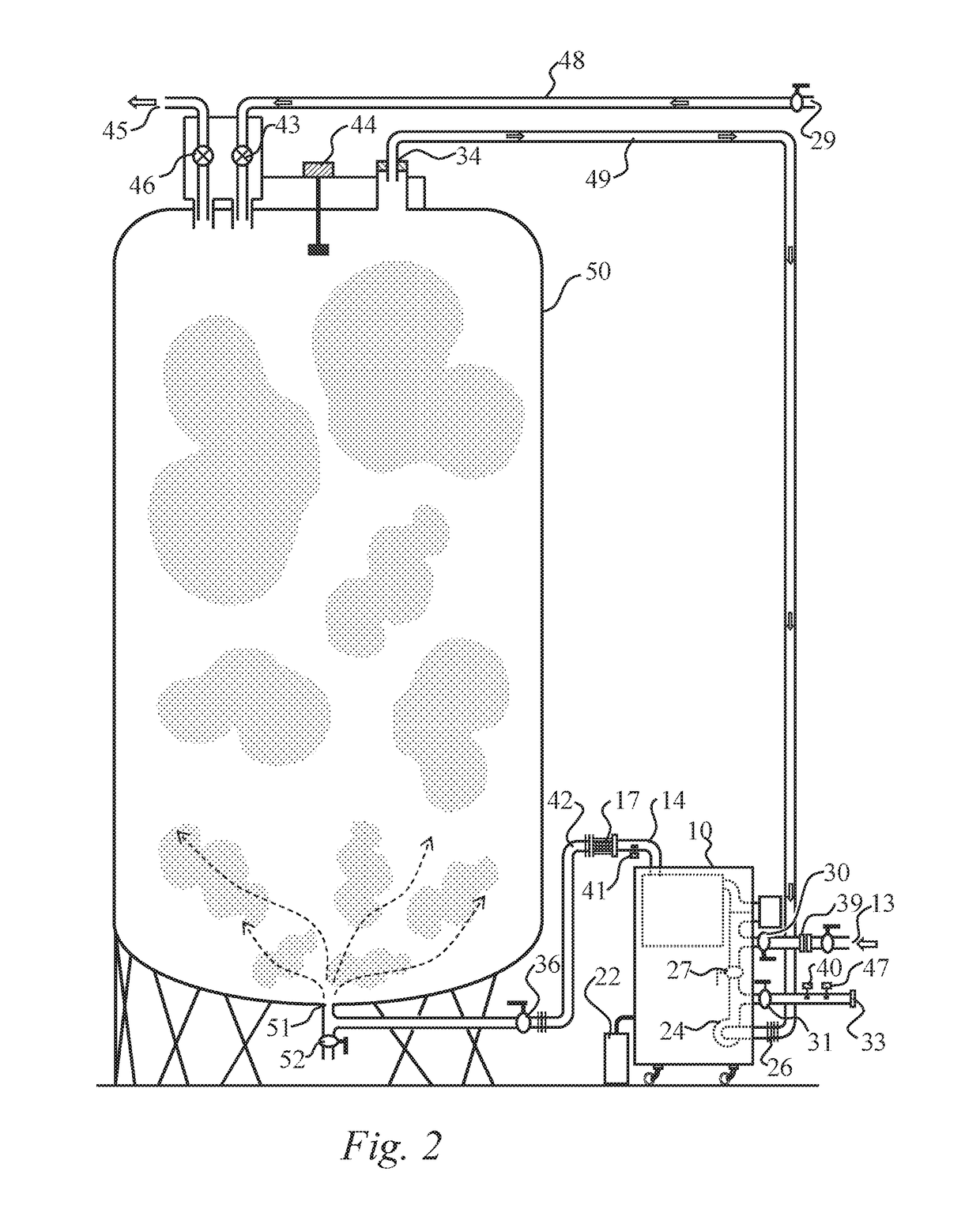

[0102]As already mentioned herein, the flooding procedure is the final step of cleaning and disinfection process of NFC juices aseptic tanks. The system of the present invention eliminate the need to perform said flooding with a liquid sanitizing solution, therefore saving time, chemical products, water, energy and reduction of effluents.

[0103]In the known flooding procedure, i.e., using a sanitizing solution in liquid state, an iodoform solution must be transferred to NFC juice aseptic tank with pumps. Said sanitizing solution enters the aseptic tank by means of a bottom valve 52 situated in base of aseptic tank 50 (see FIG. 2). As soon as the sanitizing solution begins to fill the tank, the atmospheric air within is expelled by a relief valve 46 situated on top of the aseptic tank. The cost of providing a iodoform solution for a 6 million liters aseptic tank is about US$120,000.00. The time to fill the whole aseptic tank and expel all atmospheric air is from 2 to 4 days and will d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com