Handheld dual thermal neutron detector and gamma-ray spectrometer

a dual-stage, gamma-ray spectrometer technology, applied in the direction of instruments, radiation measurement, measurement devices, etc., can solve the problems of poor phase homogeneity, and achieve the effect of improving purity and homogeneity, poor phase homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

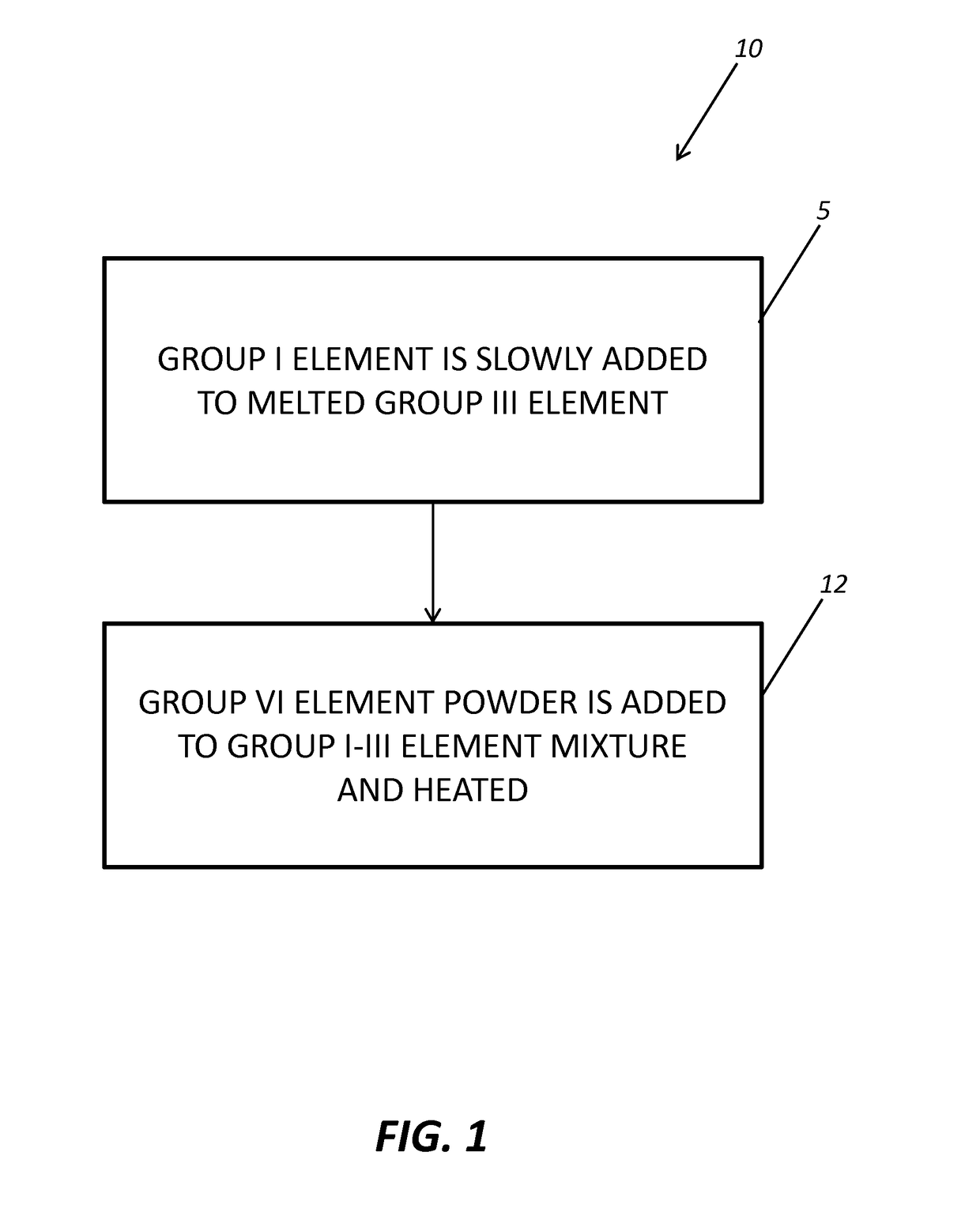

exemplary embodiment 10

[0034]Referring specifically to FIG. 1, in the first exemplary embodiment 10, the Group VI elemental powder is added directly to the I-III alloy and heated to 700-900 degrees C. (depending on the group VI element) in a crucible 12. The reaction is allowed to proceed to completion and then cooled. Because the I-III compound is formed in an initial reaction step, the stoichiometry is defined as one mole for each element. Addition of the Group VI element for the final I-III-VI reaction has lower overall stoichiometric variability throughout the charge.

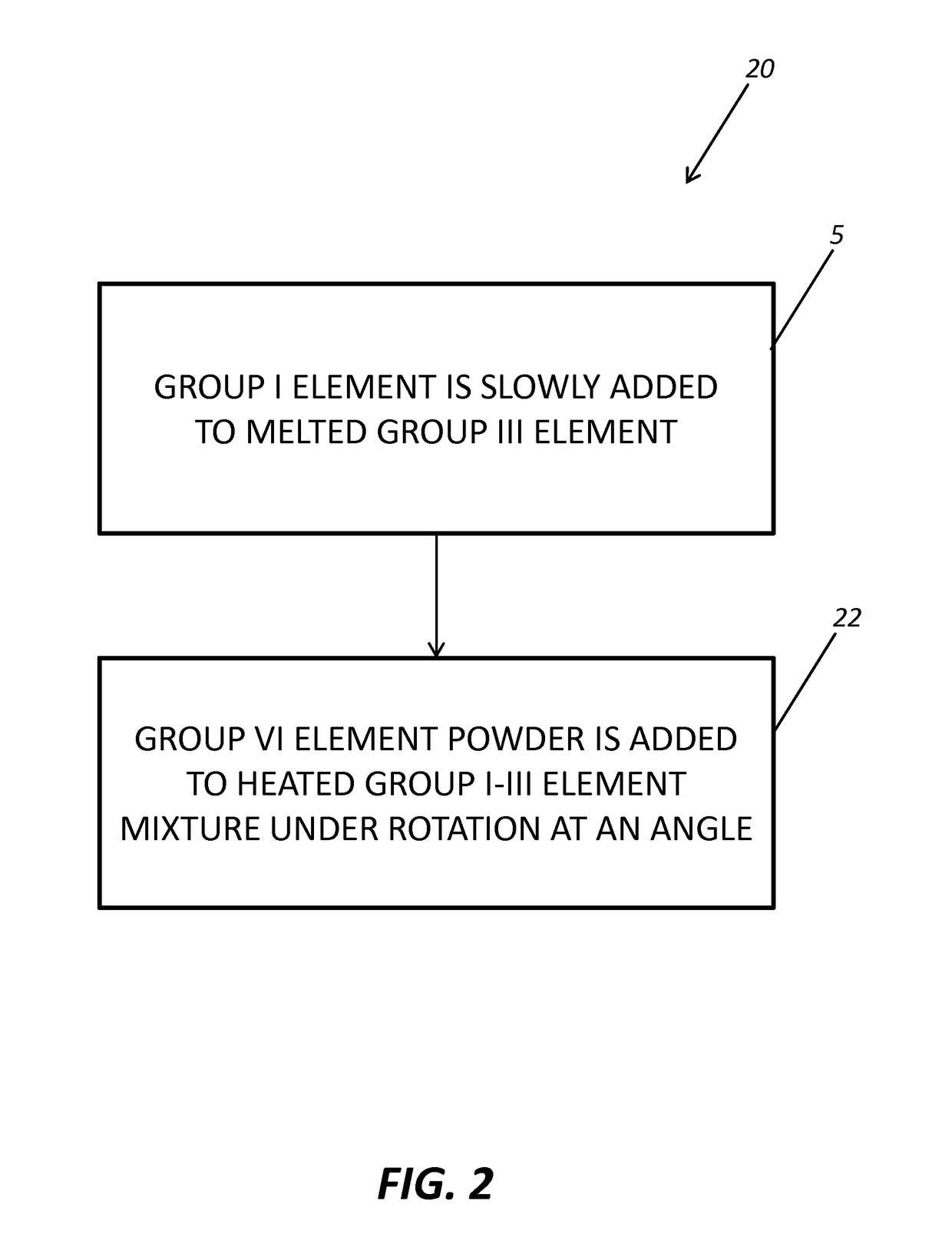

exemplary embodiment 20

[0035]Referring specifically to FIG. 2, in the second exemplary embodiment 20, the addition of the Group VI element into a single crucible is as with the first exemplary embodiment; however, the constituents are mixed at elevated temperature with constant crucible rotation at an angle 22, for example about 20 degrees. Rotation further promotes mixing during the synthesis to reduce phase variability.

exemplary embodiment 30

[0036]Referring specifically to FIG. 3, the third exemplary embodiment 30 involves vapor transport of the Group VI element 32. The previously prepared I-III compound is placed in one well of a crucible, while the Group VI element is placed in an adjacent well. As the mixture is heated to 700-900 degrees C., the Group VI element slowly vaporizes and is transported through thermal currents to the melted group I-III well. The reaction then occurs to form I-III-VI2. Vapor transport further slows the reaction to minimize overheating and promote a single phase synthetic charge.

[0037]It should be noted that the methods of the present invention are not limited to the synthesis of semiconductor materials. Doping with an activator (e.g., Group IV element) may be performed to create a scintillator material, for example.

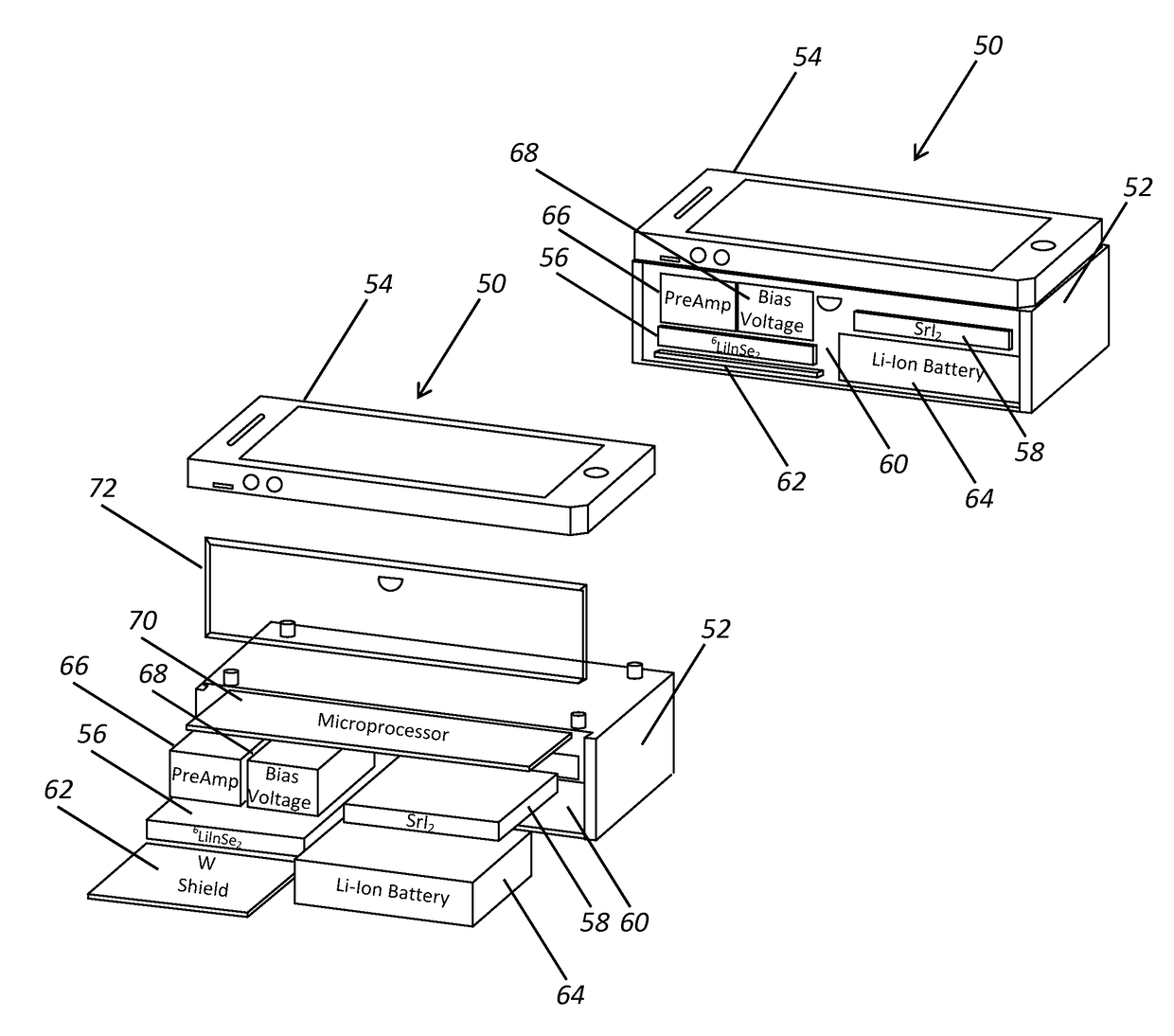

[0038]Referring now specifically to FIG. 4, in one exemplary embodiment of the handheld dual thermal neutron detector and gamma-ray spectrometer 50 of the present disclosure, al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com