Growth method of dendritic crystal structure that provides directional heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

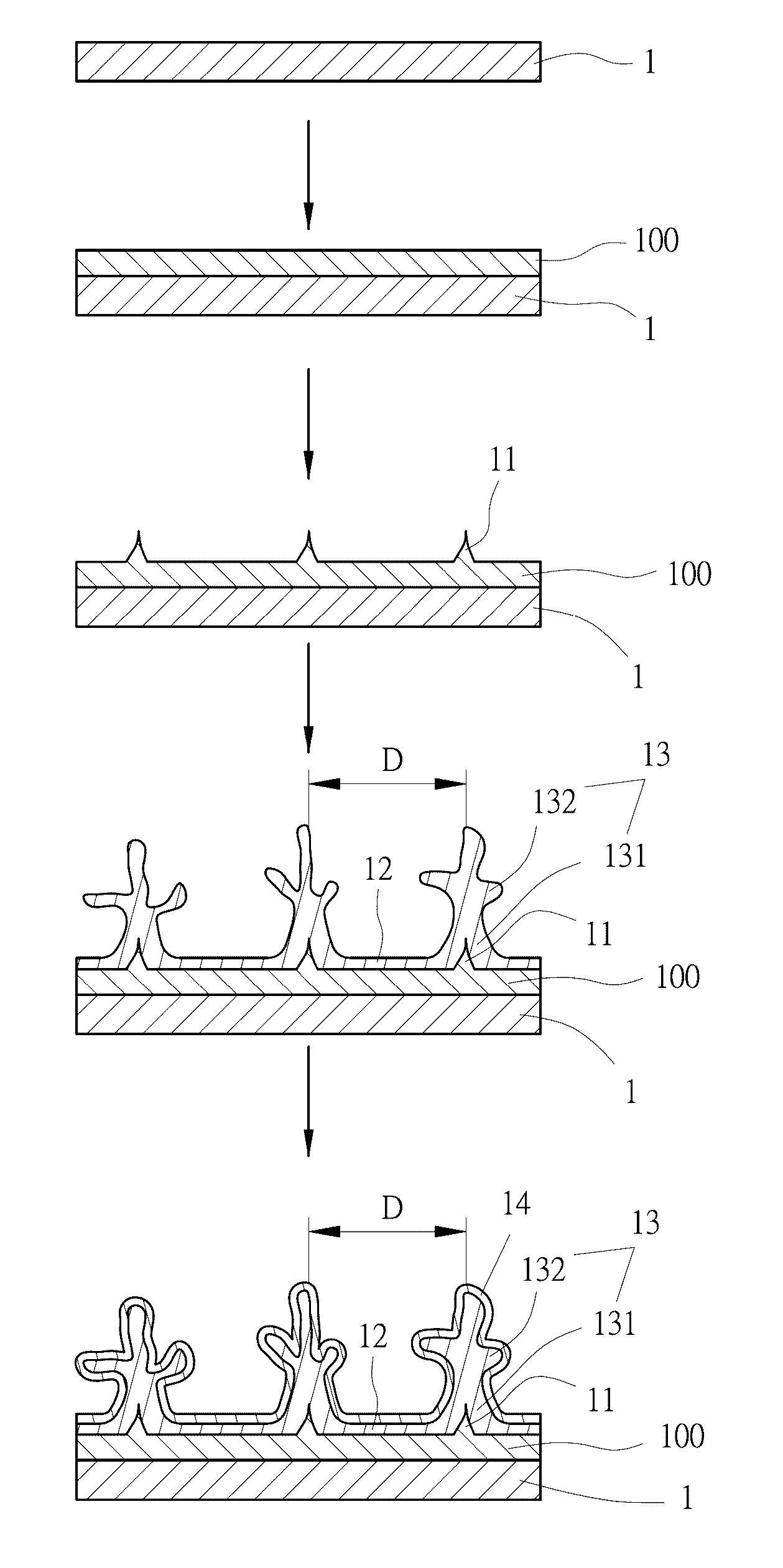

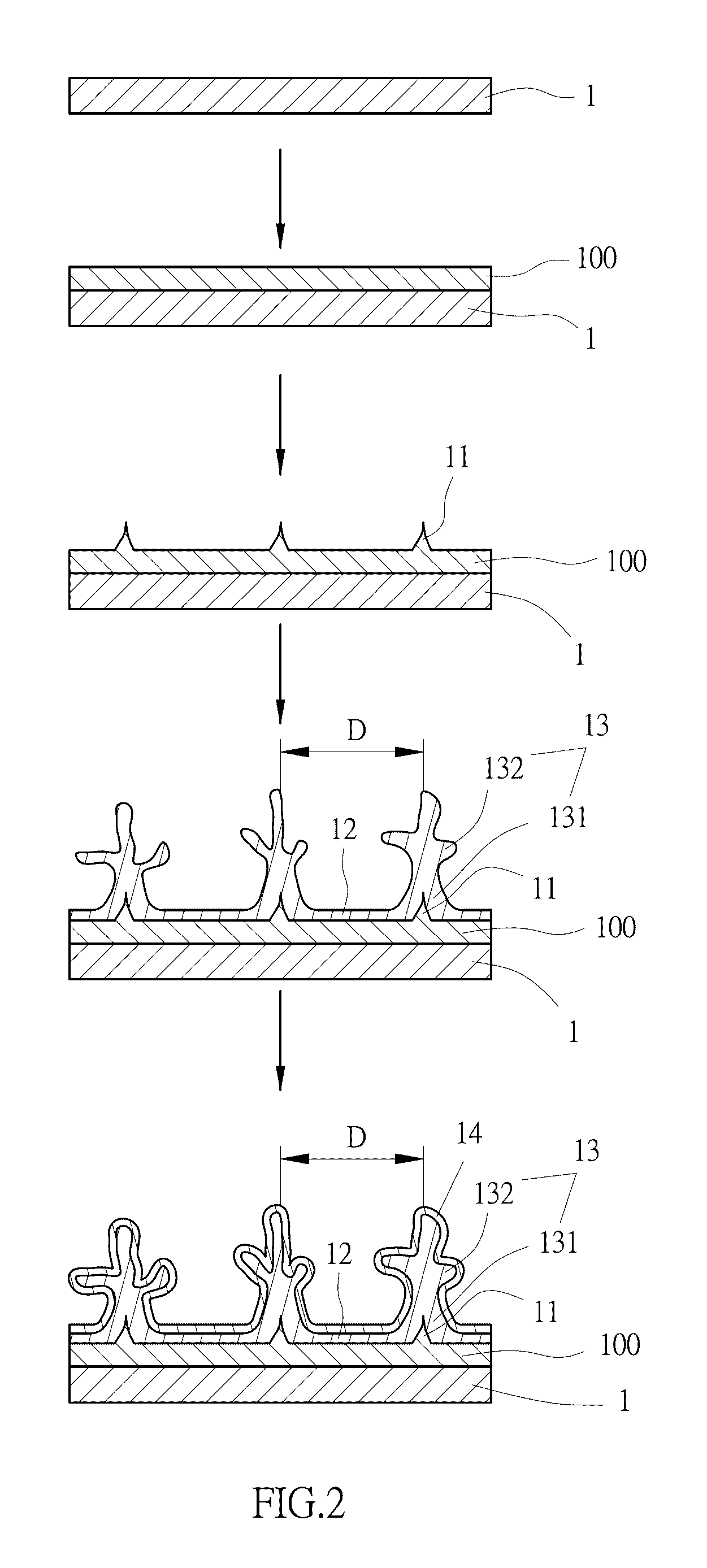

[0063]The above and other detailed contents, features and effects with respect to the growth method of dendritic crystal structure that provides directional heat transfer of the present invention will be clearly presented in the following preferred embodiments and accompanying drawings.

[0064]Referring first to FIG. 1 and FIG. 2, which show a step flow diagram and a preparation flow diagram, respectively, of an embodiment of a growth method of dendritic crystal structure that provides directional heat transfer of the present invention, comprising the following steps: A. Providing a substrate (1), whereby a substrate (1) is provided with a plurality of crystal defects (11) separated at intervals. The definition of the crystal defects (11) in the present invention is hereby described as not only including forms whereby there is damage to the regular crystal structure such as general point defects and line defects, but also includes whisker type defects. It is preferred that the substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com