Coated substrates and methods of producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]The following detailed description is merely exemplary in nature and is not intended to limit the various embodiments or the application and uses of the invention. Furthermore, there is no intention to be bound by any expressed or implied theory presented in the preceding technical field, background, brief summary, or the following detailed description.

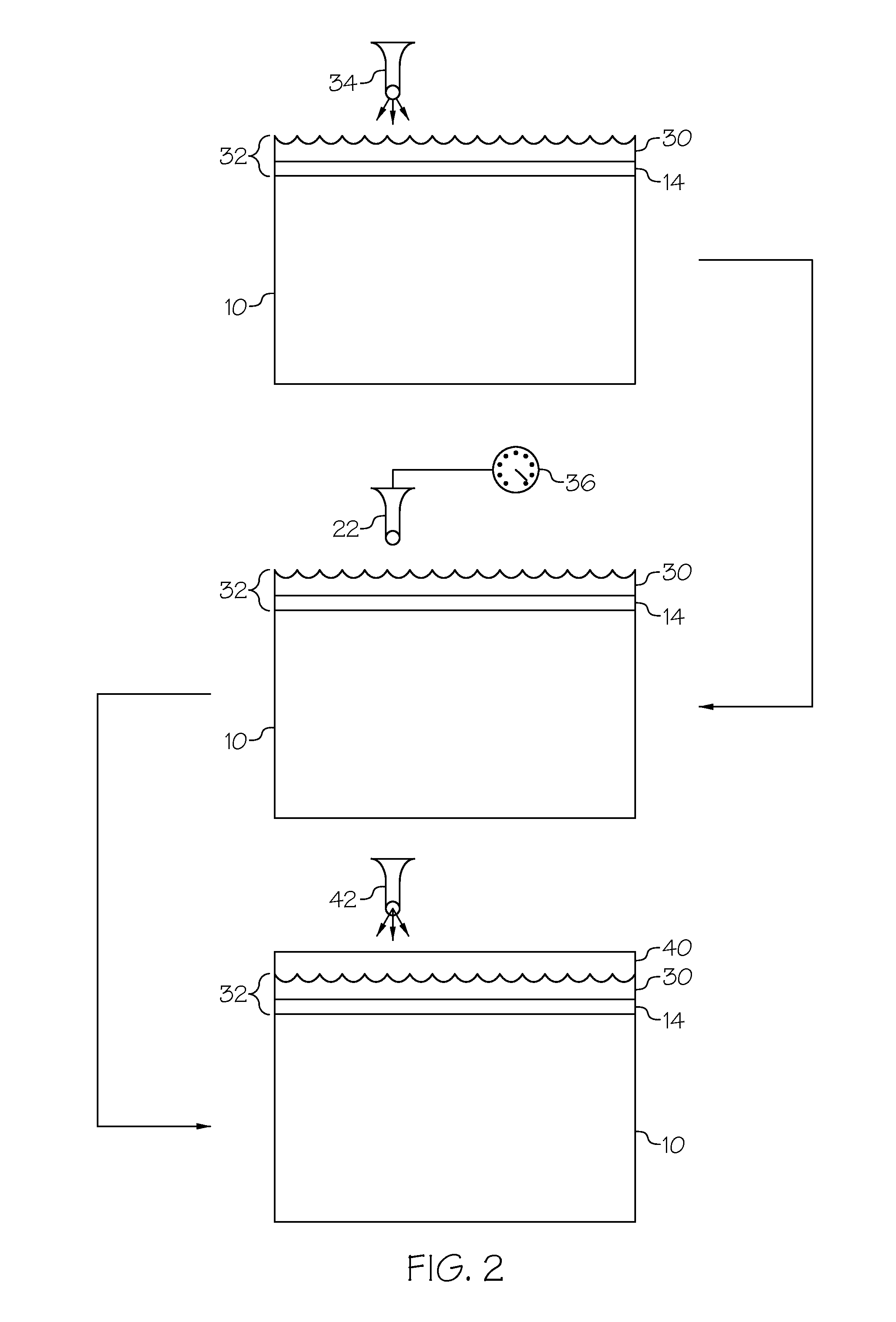

[0014]Bond coats are used to adhere an environmental barrier coating layer to a ceramic substrate. Adhesion is improved by greater surface roughness in many embodiments, so a bond coat with greater surface roughness may improve adhesion. Plasma sprayed bond coats often have a higher surface roughness than brazed bond coats, but the use of a brazed bond coat layer between a plasma sprayed bond coat layer and the ceramic substrate can improve the adhesion of the plasma sprayed layer to the substrate.

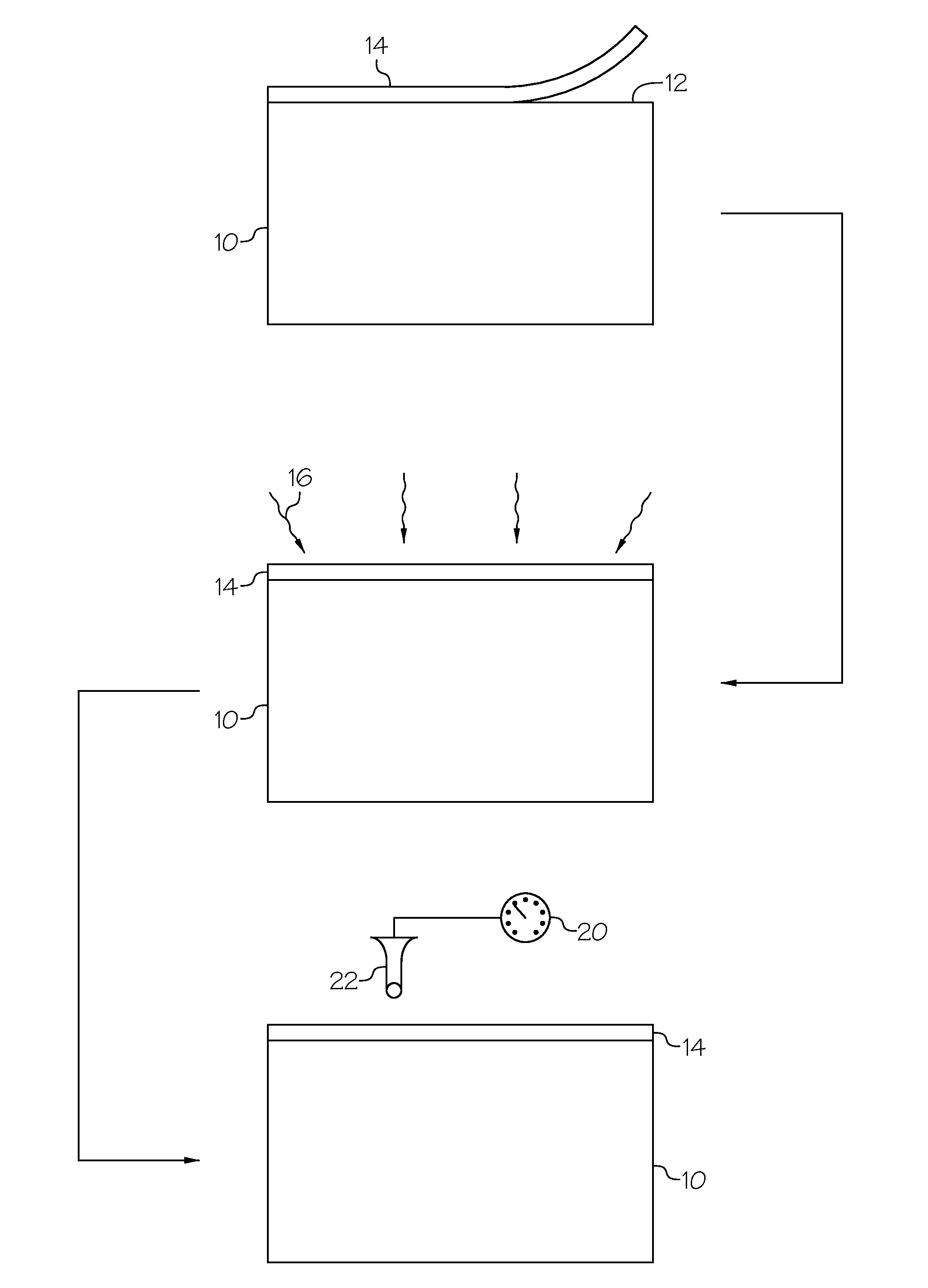

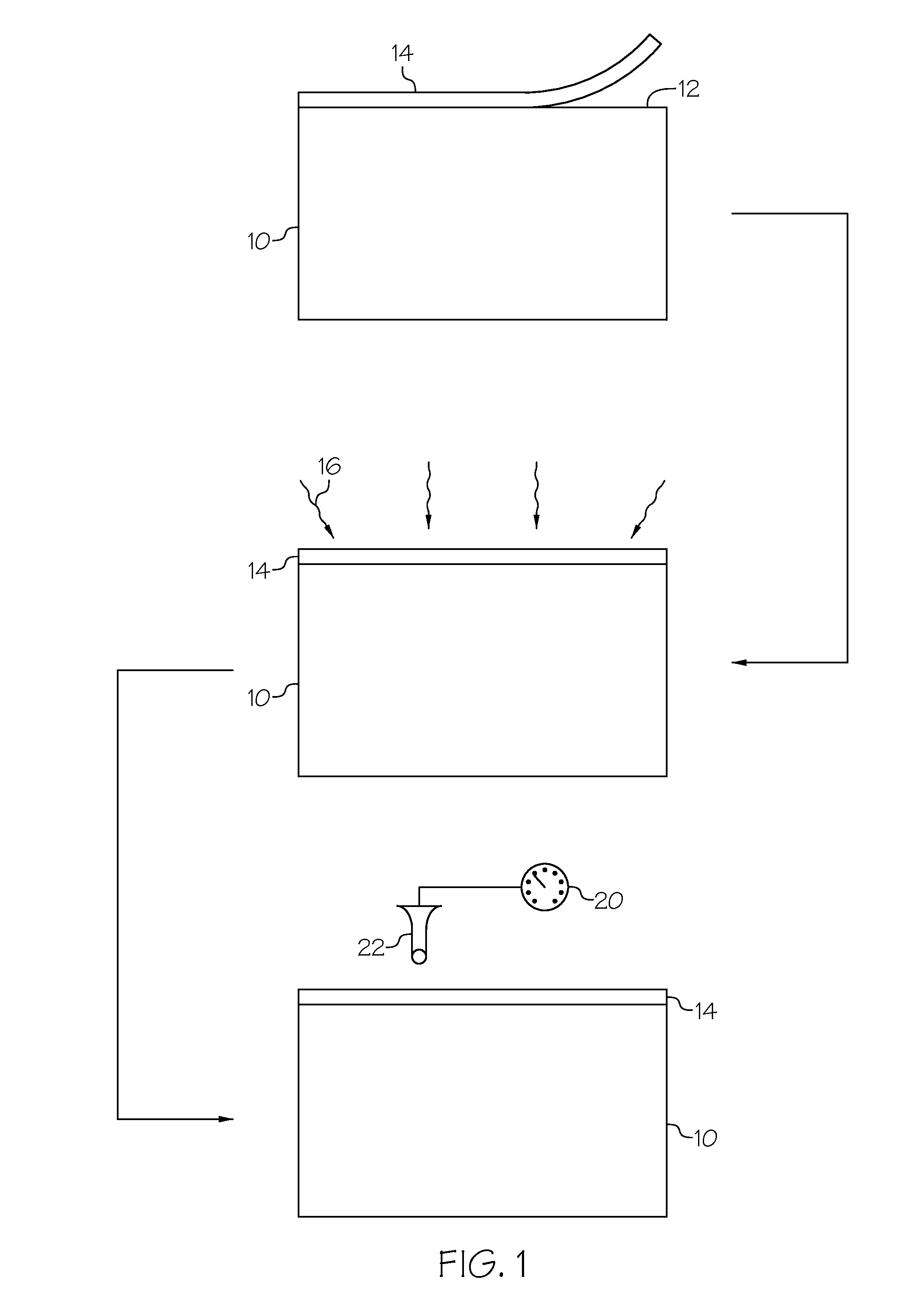

[0015]Referring to an exemplary embodiment illustrated in FIG. 1, a component includes a substrate 10. The substrate 10 includes a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com