Micro-resonator and fiber taper sensor system

a micro-resonator and sensor system technology, applied in the direction of nanoparticle analysis, instruments, material analysis, etc., can solve the problems of high cost, high sensitivity and resolution, and the known particle detection system uses conventional microscopic techniques, etc., to achieve the effect of optimizing performance and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

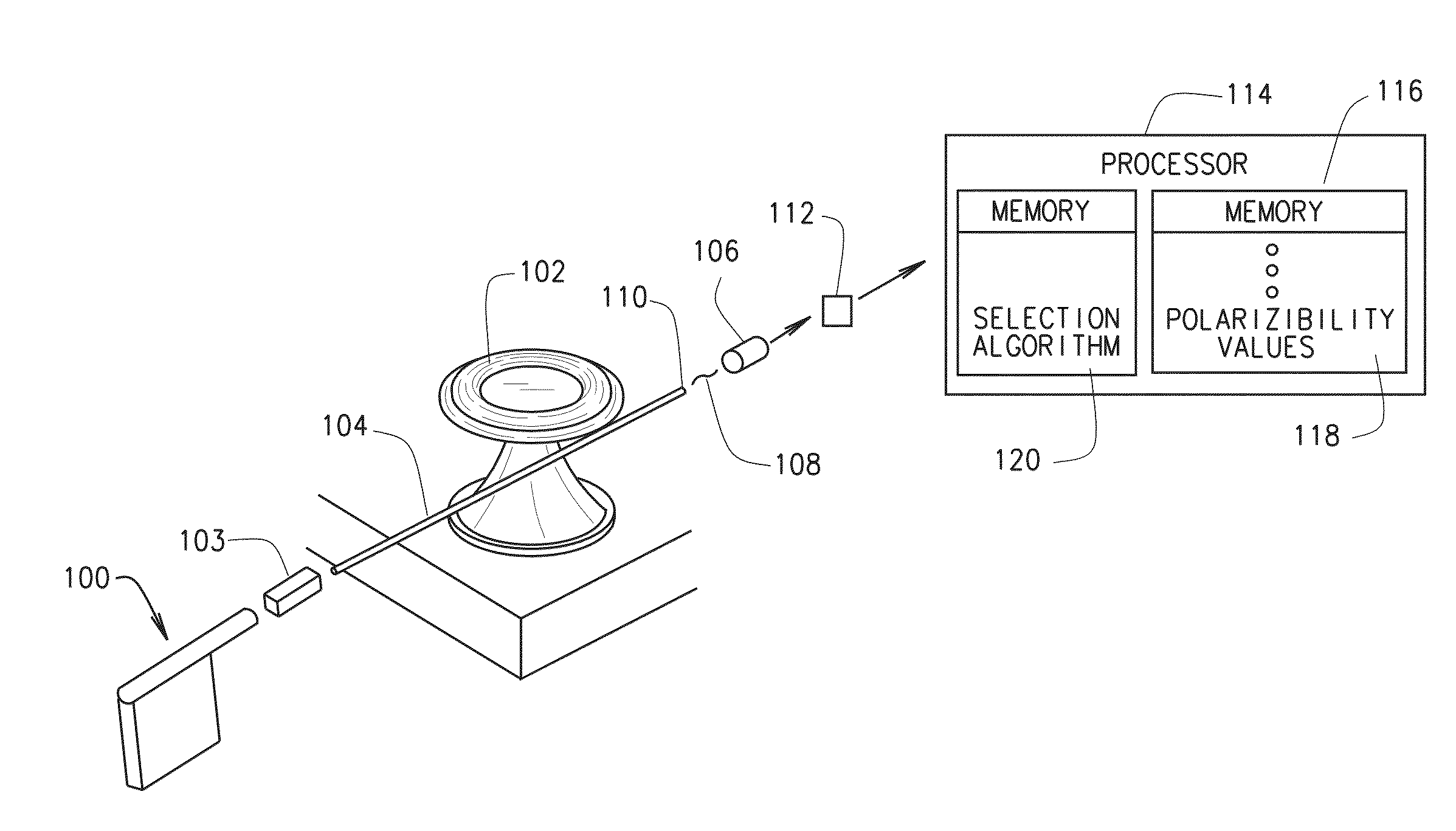

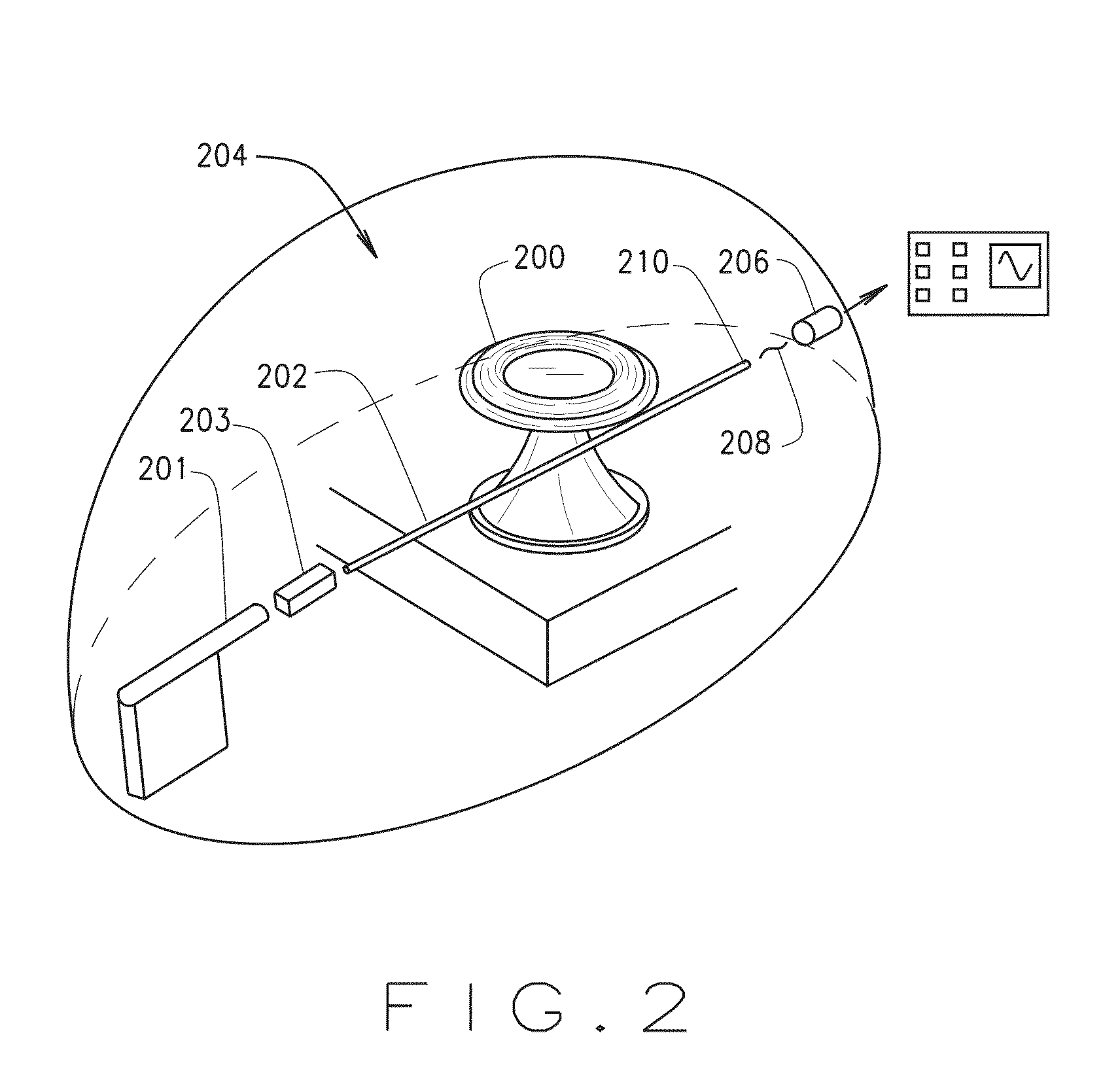

[0057]According to the embodiment(s) of the present invention, various views are illustrated in FIG. 1-9 and like reference numerals are being used consistently throughout to refer to like and corresponding parts of the invention for all of the various views and figures of the drawing. Also, please note that the first digit(s) of the reference number for a given item or part of the invention should correspond to the FIG. number in which the item or part is first identified.

[0058]This application claims the benefit of and priority to U.S. Provisional Application Ser. No. 62 / 113,610, Filed Feb. 9, 2015, entitled MICRORESONATOR AND FIBER TAPER BASED SENSOR SYSTEMS, which is hereby incorporated in its entirety herein.

[0059]One implementation of the present technology comprising a micro-resonator and fiber taper based system teaches an apparatus and method for sensing particles. By way of background, particle binding splits a WGM into two spectrally shifted resonance modes, forming a sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| polarizability | aaaaa | aaaaa |

| transmission | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com