A system and method for separation and purification of dissolved rare earth/precious metals elements/compounds

a rare earth/precious metals element and purification technology, applied in the direction of semi-permeable membranes, material analysis by electric/magnetic means, electrolysis components, etc., can solve the problems of wasting a great deal of time, resources and expertise in separating and extracting single rees, and requiring a large amount of time, resources and expertis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

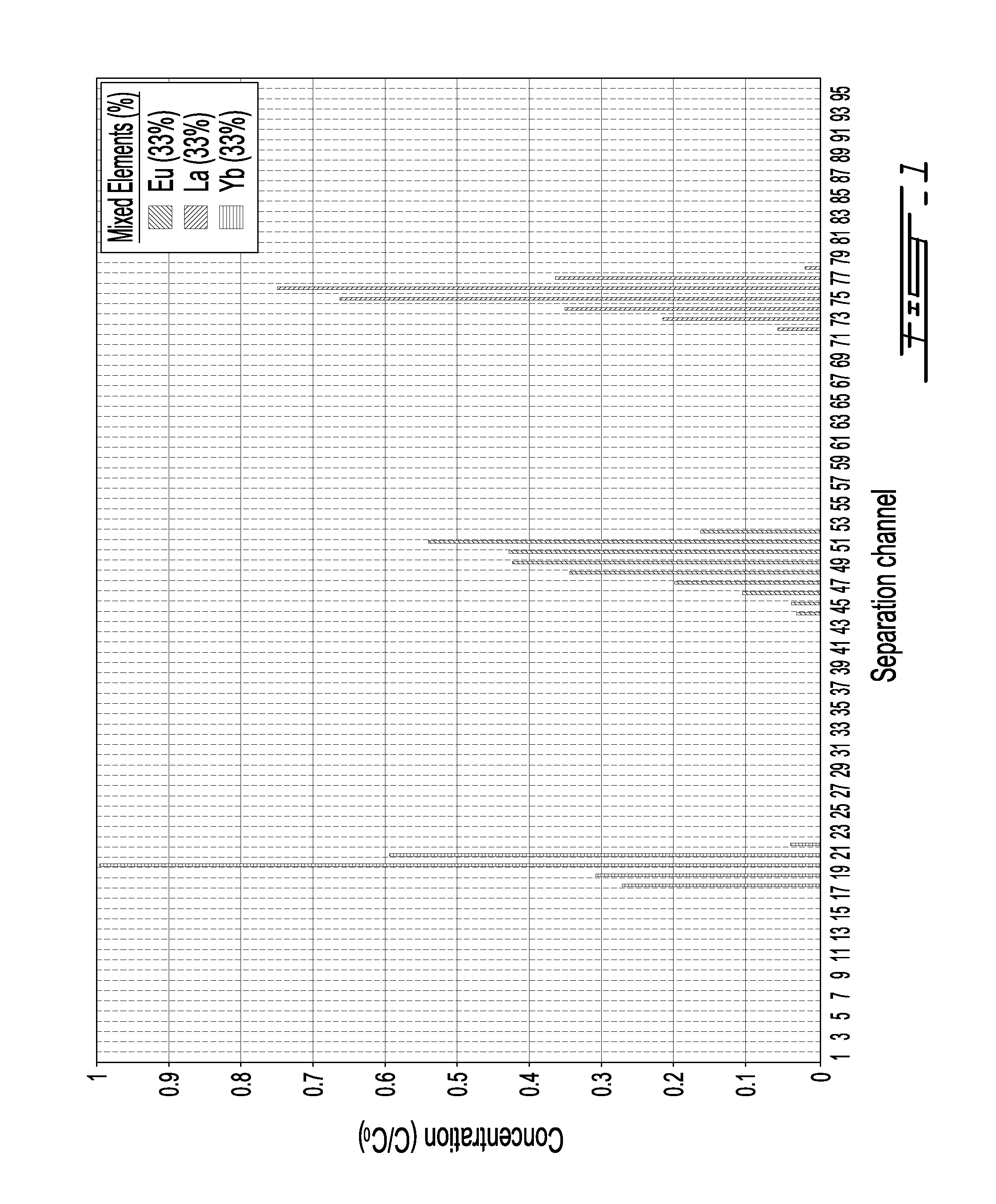

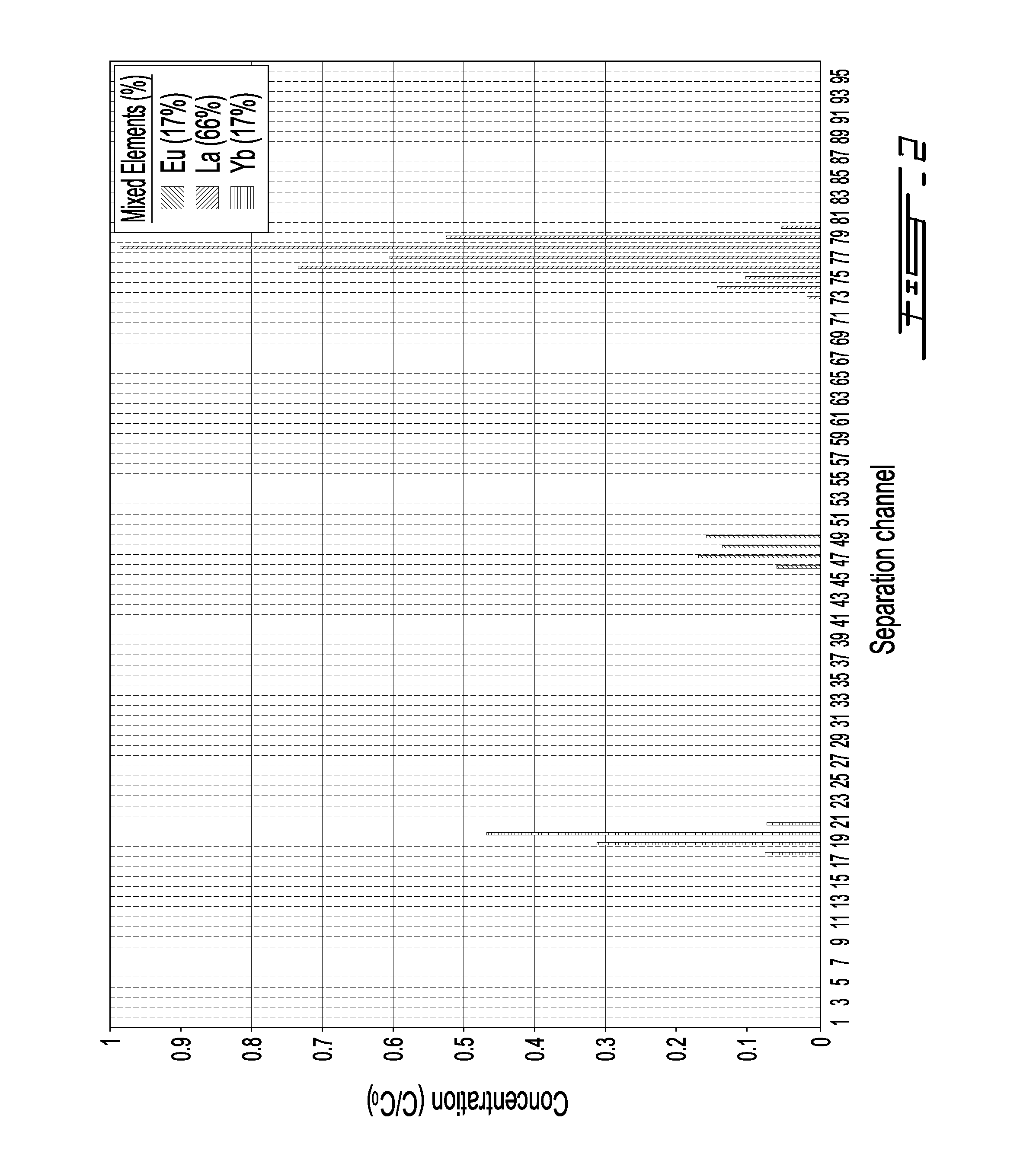

[0025]The present method and system use electrophoretic mobility variation of REE or precious metals in an electrical field to separate them, thereby reducing the cost of separation and circumventing intrinsic environmental issues of solvent based methods and systems. At the purification stage, the present method and system remove impurities and separate REE / precious metal elements simultaneously. The present method and system will be hereinafter described in relation to REE.

[0026]Free flow electrophoresis (FFE) is used to fractionate REE ions, using a uniform electric field applied perpendicular to a solution flow and separating the mobile ions based on electrophoretic mobility (Ui).

[0027]Basically, in a FFE system, the translational flow of ions in a laminar flow regime along a channel is affected by a perpendicular electrophoretic force exerted by a static electric field on each ion. The magnitude of this force and hence the deviation of the ions form straight trajectories along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com