Training Projectile and Training Cartridge

a projectile and projectile technology, applied in the field of training projectiles, can solve the problems of high cost of such rounds, and high cost of cartridge ammunition, and achieve the effect of simple dimension resistance and low cost of cartridge cases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

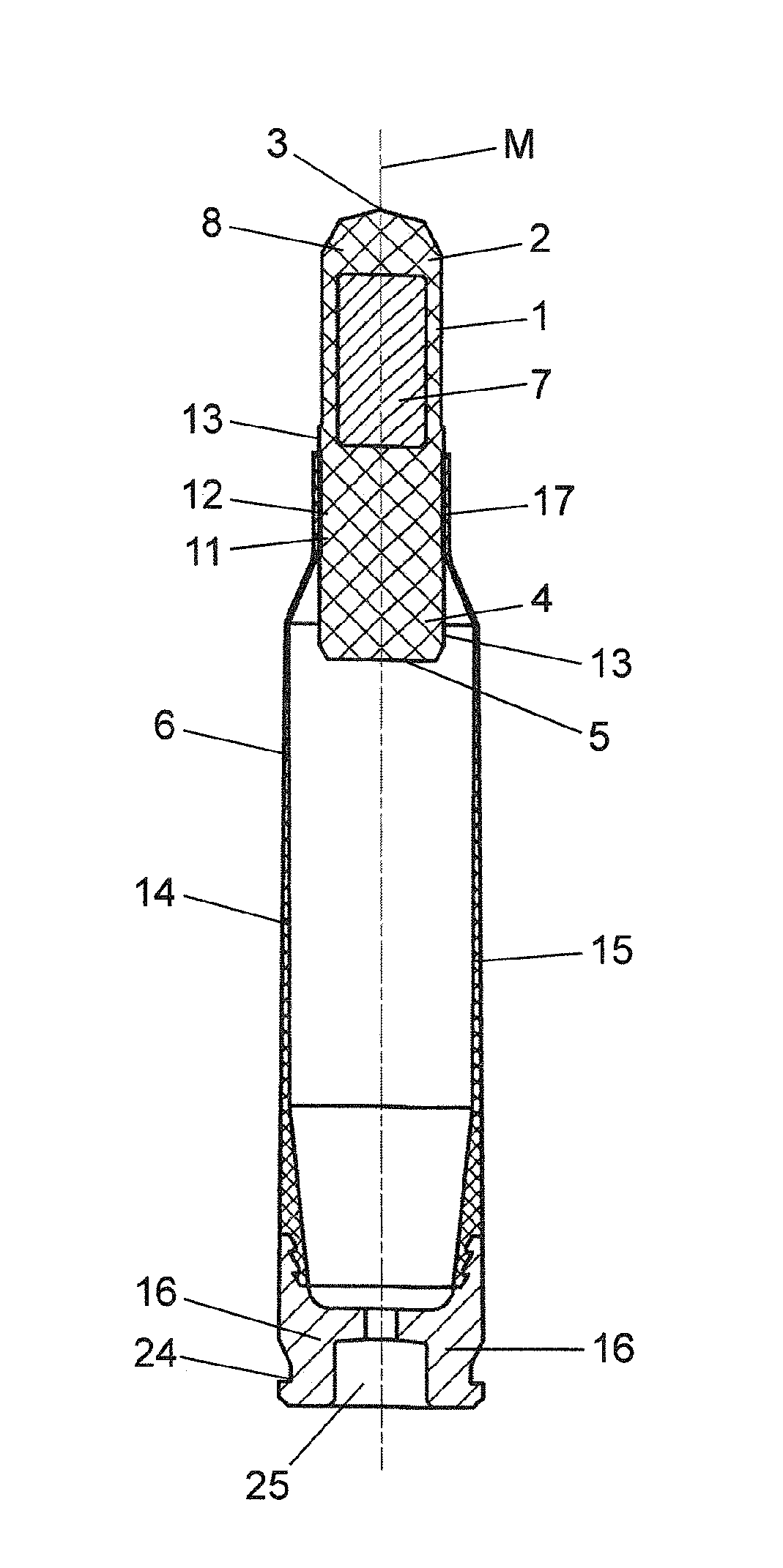

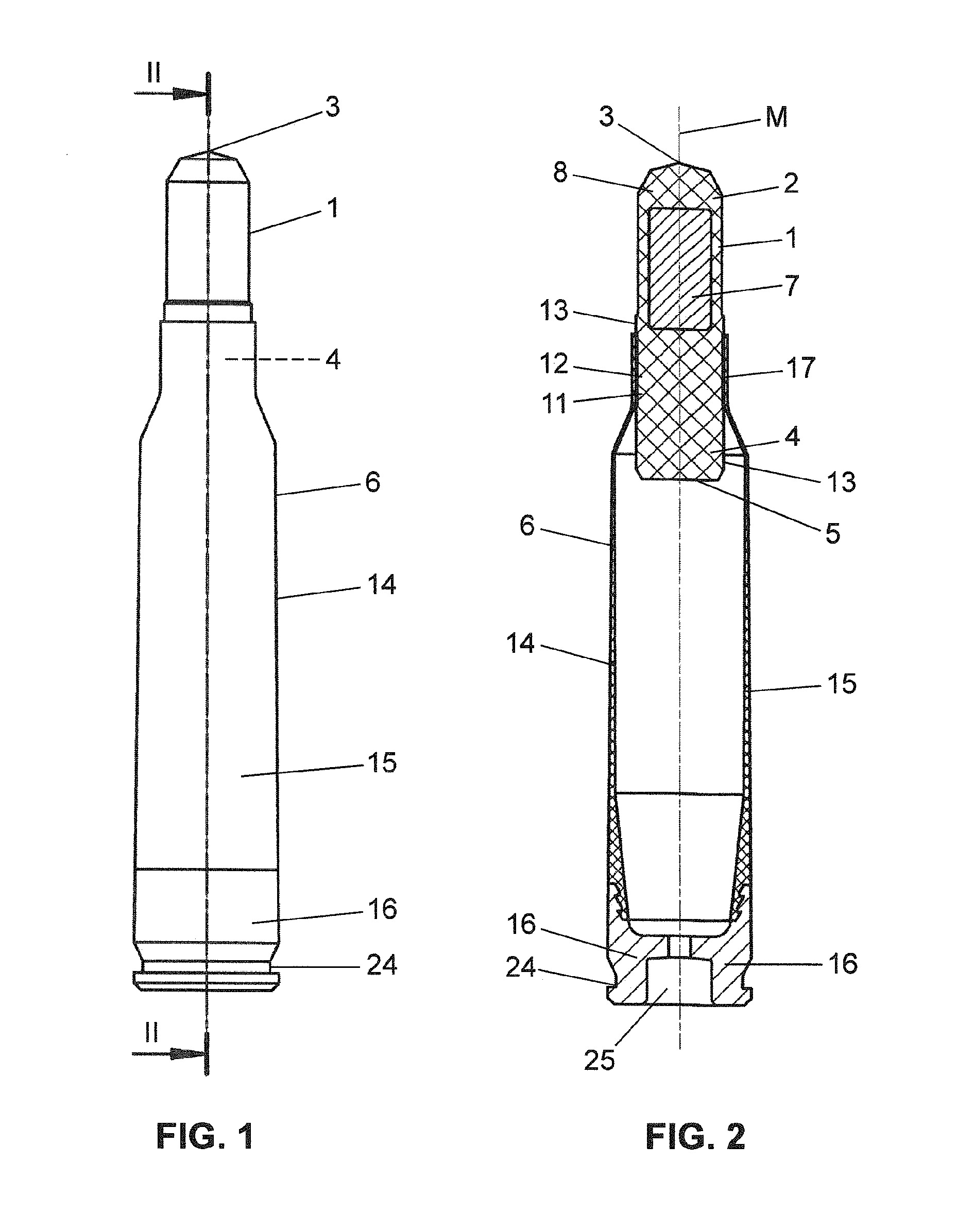

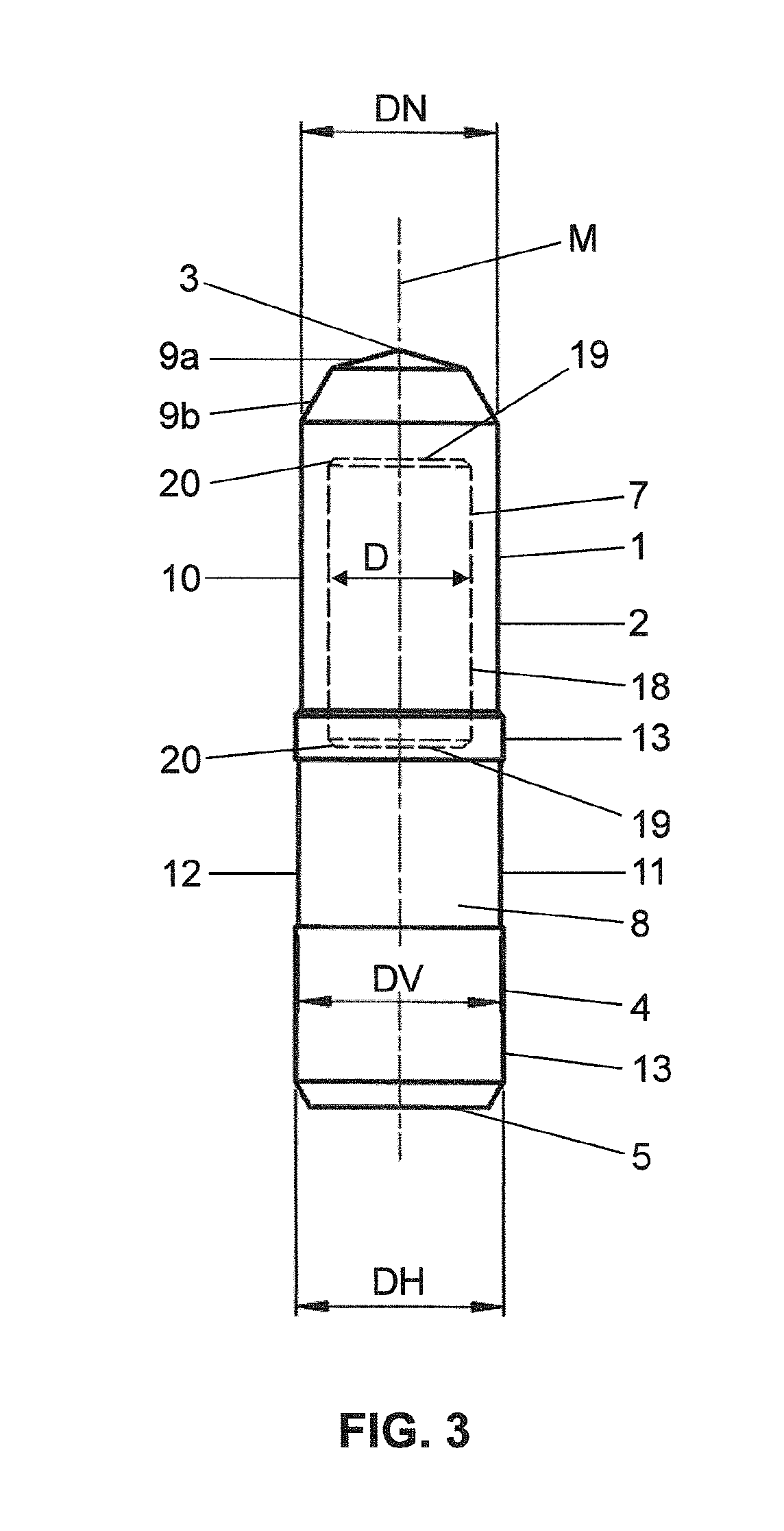

[0010] the projectile comprises a projectile core of metal with a plastic jacket surrounding the projectile core and at least partly determining the external shape of the projectile. The projectile core is thereby intrinsically stable. It is thus preferably a solid projectile core.

second embodiment

[0011] the projectile comprises a projectile core made of a mixture of plastic and metal with a plastic jacket surrounding the projectile core and at least partly determining the external shape of the projectile. It is e.g. conceivable here that there are metal parts in the plastic mixture, wherein the plastic mixture is used as a matrix for holding the metal parts.

third embodiment

[0012] the projectile comprises a projectile core of solid or loose metallic powder with a plastic jacket surrounding the projectile core and at least partly determining the external shape of the projectile. The powder can be disposed loosely in the jacket, wherein an internal space in which the powder is disposed is provided by the jacket. The powder can, however, also e.g. be made into a solid composite by a sinter process, wherein said solid composite is then surrounded by the jacket.

[0013]Because of the formation of the projectile with a metallic or metal-containing core and a plastic jacket, a round can be provided that has very similar ballistic properties to conventional rounds. The metallic core thereby ensures a suitable weight, while the plastic jacket with the external shape determines the aerodynamics of the projectile.

[0014]The projectile core preferably has the shape of a cylinder. The projectile core can thus be particularly simply manufactured.

[0015]Preferably, the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com