Miniature electro-pyrotechnic igniter, and ignition head for the same

a technology of electro-pyrotechnic ignition and ignition head, which is applied in the direction of ammunition fuzes, blasting cartridges, weapons components, etc., can solve the problems of non-uniform, irregular, and unfavorable uniform heat and ignition of the end surface of the elongate, and achieve the effect of overcoming or reducing one or two

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

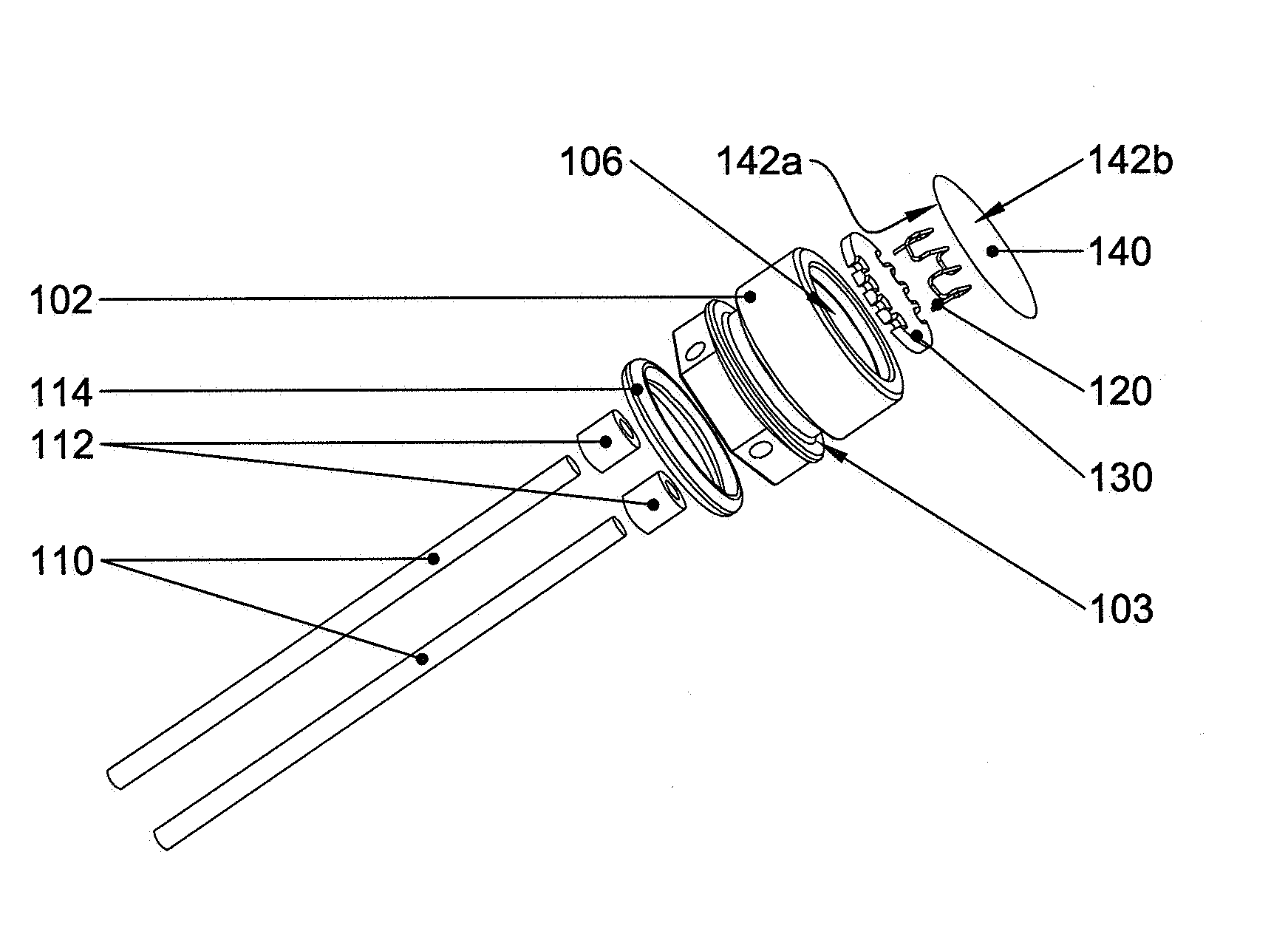

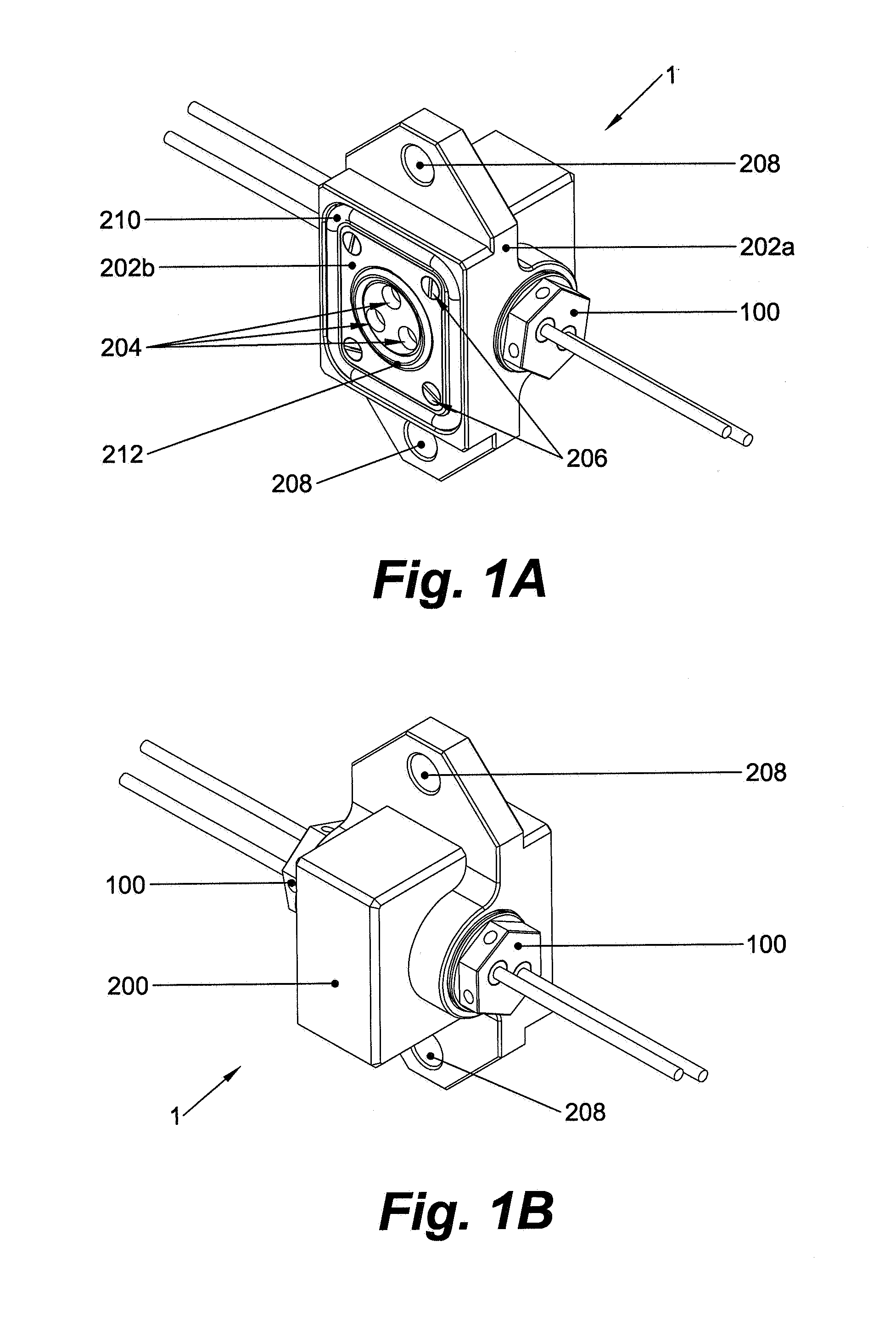

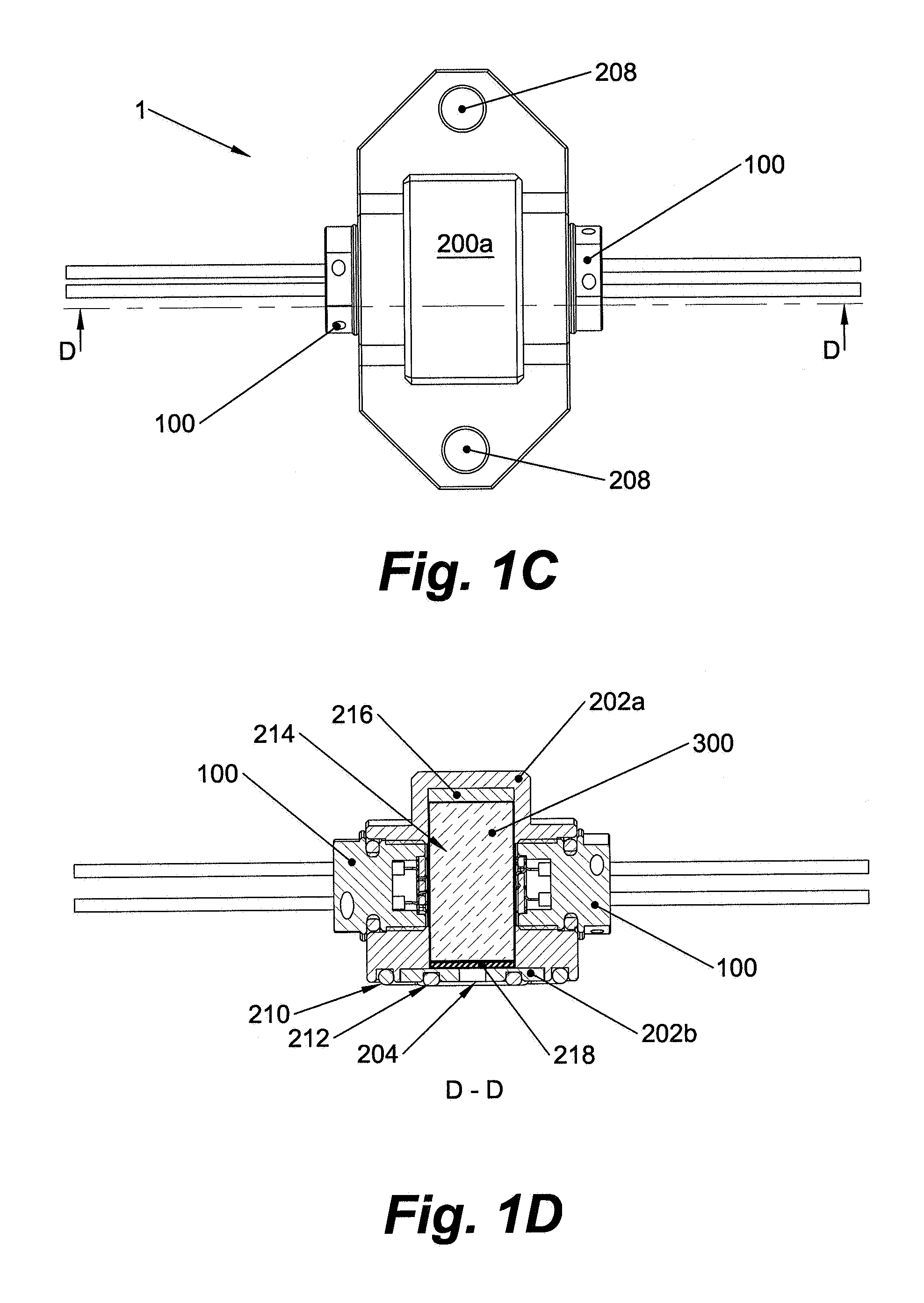

[0017]FIG. 1 schematically illustrates an exemplary embodiment of an electro-pyrotechnic igniter 1 according to the present disclosure. Such an electro-pyrotechnic igniter 1 may include at least one ignition head 100. The embodiment of the electro-pyrotechnic igniter depicted in FIG. 1 includes two identical ignition heads 100, whose construction is schematically illustrated in more detail in FIG. 2. Below, the construction and operation of the ignition head 100 and the electro-pyrotechnic igniter 1 according to the present disclosure are described in general terms, where appropriate with reference to FIGS. 1-2.

[0018]The ignition head 100 according to the present disclosure may be characterized as a non-pyrotechnic, electric ignition head 100. That is, the electrically powered ignition head 100 may itself be void of any pyrotechnic composition, and merely be configured to effect the ignition of a separate or external pyrotechnic charge 300 when it is brought in contact therewith, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com