Plug and Gun Apparatus and Method for Cementing and Perforating Casing

a gun and perforating technology, applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., can solve the problems of insufficient data recording today to effectively measure the success or failure of a primary cement job, and not all wells that are drilled and casing strings cemented in place during the well operation, etc., to achieve the effect of increasing costs and additional drilling tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

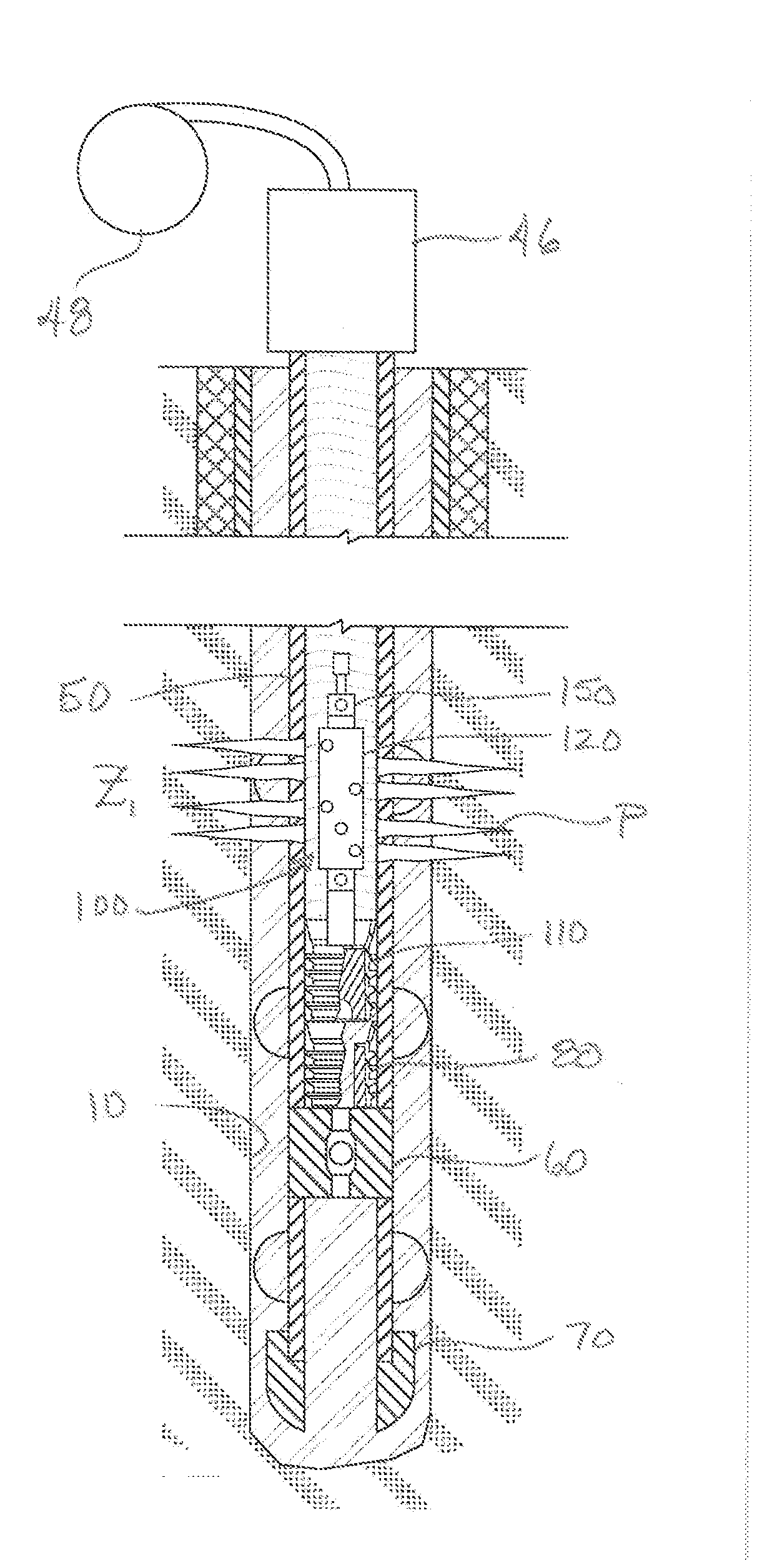

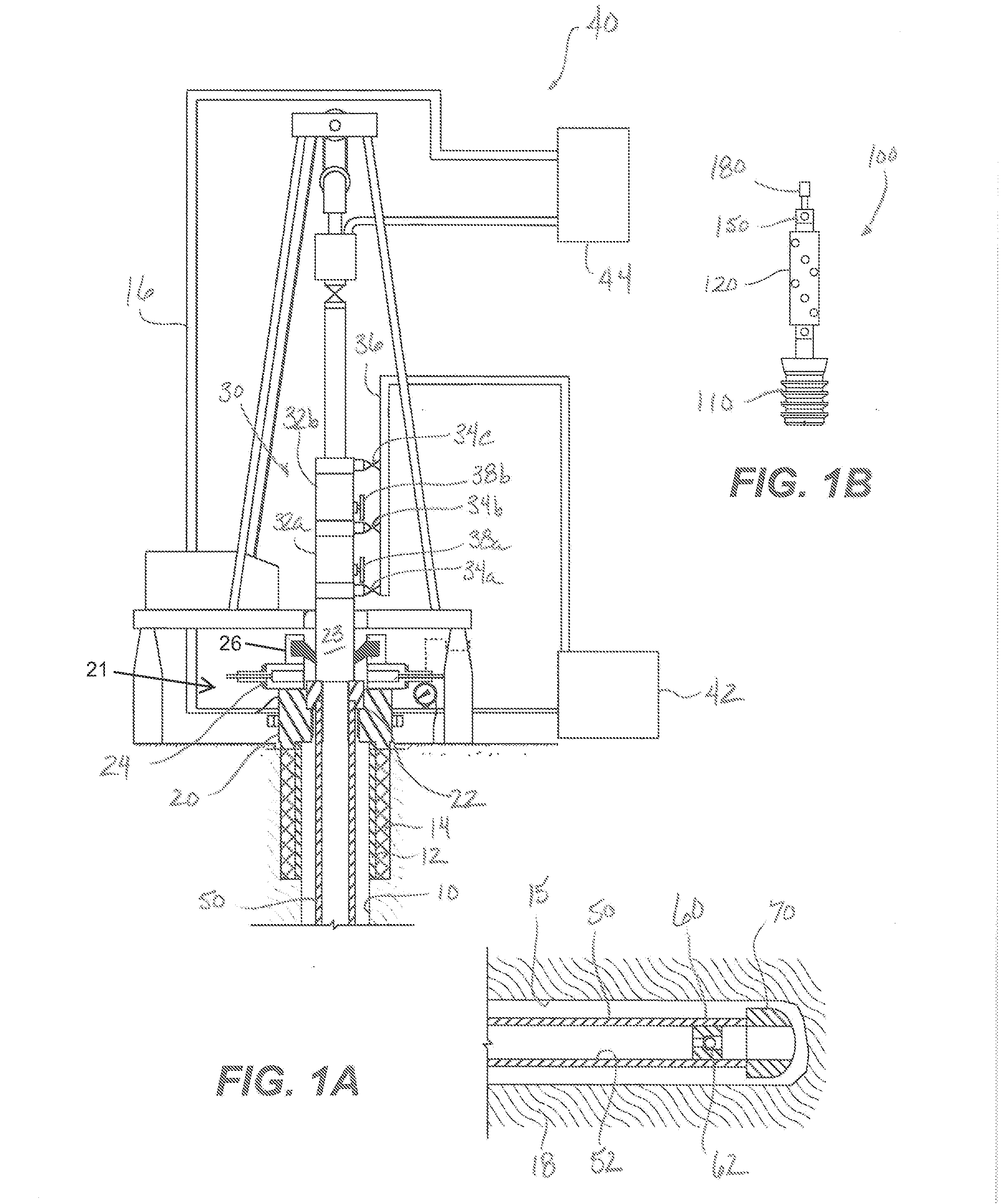

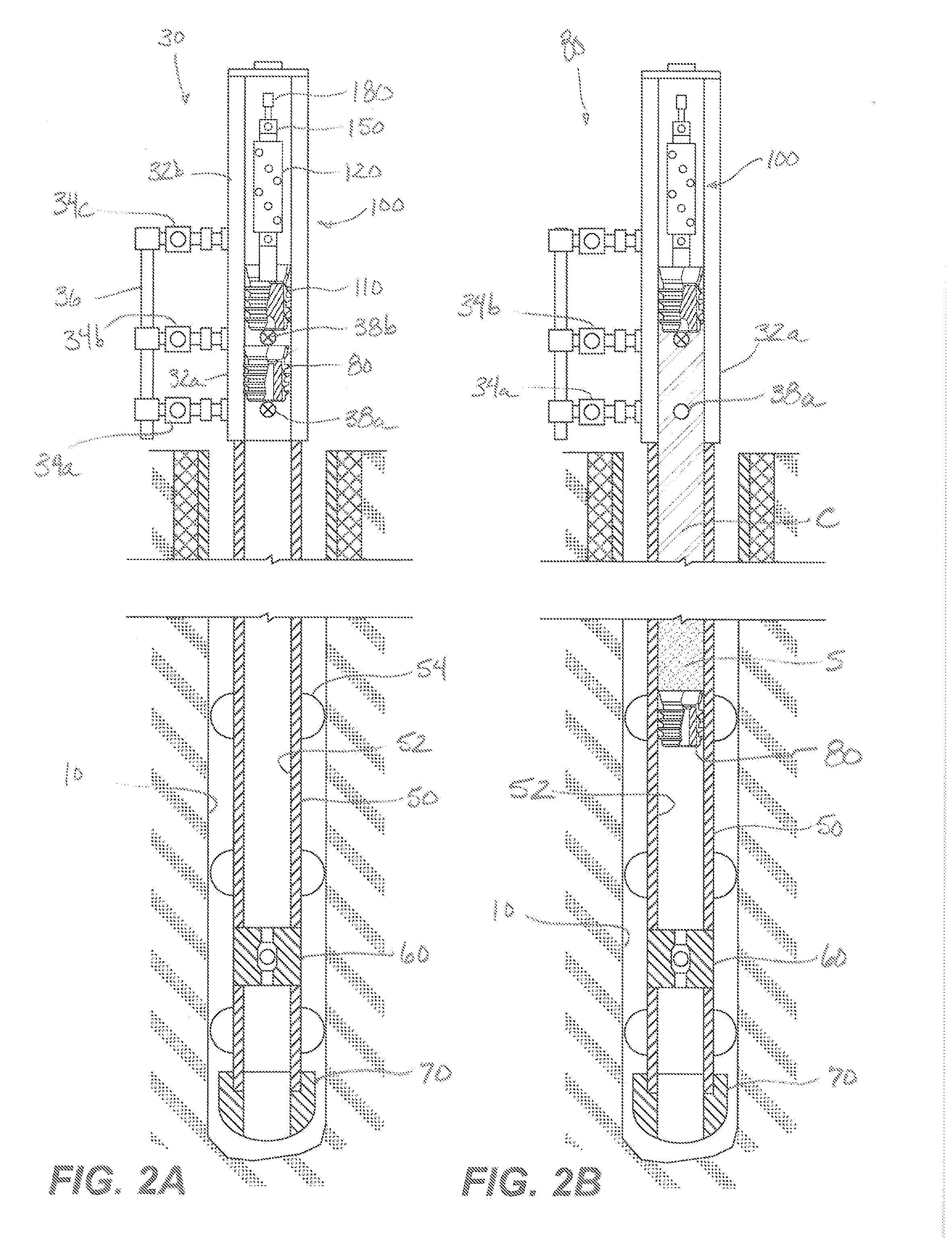

[0045]As shown in FIG. 1A, a wellhead 20 at a rig 16 is mounted on outer casing 12 deployed into a wellbore 10, and a casing adapter 23 connects a pressure control assembly 21 of the wellhead 20 to a cementing head 30. The pressure control assembly 21 typically includes a blowout preventer (BOP) 24, a rotating control device (RCD) 26, a variable choke valve, and other conventional components.

[0046]A fluid system 40 includes a cement pump 42, a mud pump 44, and other components typically used on a rig for drilling, cementing, and production operations. Various valves, spools, rotorary table, top drive, derrick, traveling block, drawworks, and other conventional components are included, but may not be discussed herein. In any event, the wellbore 10 may be a land based wellbore as shown, or it may be a subsea wellbore 10 with suitable modifications to the wellhead 20 and other components.

[0047]The cementing head 30 includes launchers 32a-b and a manifold 36 having trunks, branches, shu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com