Water proofing membrane, and a method for making a water proofing membrane

a water proofing membrane and water proofing technology, applied in papermaking, transportation and packaging, synthetic resin layered products, etc., can solve the problem of not being able to easily reach the bituminous mass, and achieve the effect of reducing the reflective effect of titanium dioxide, increasing heat absorption, and worsening heat absorption over tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

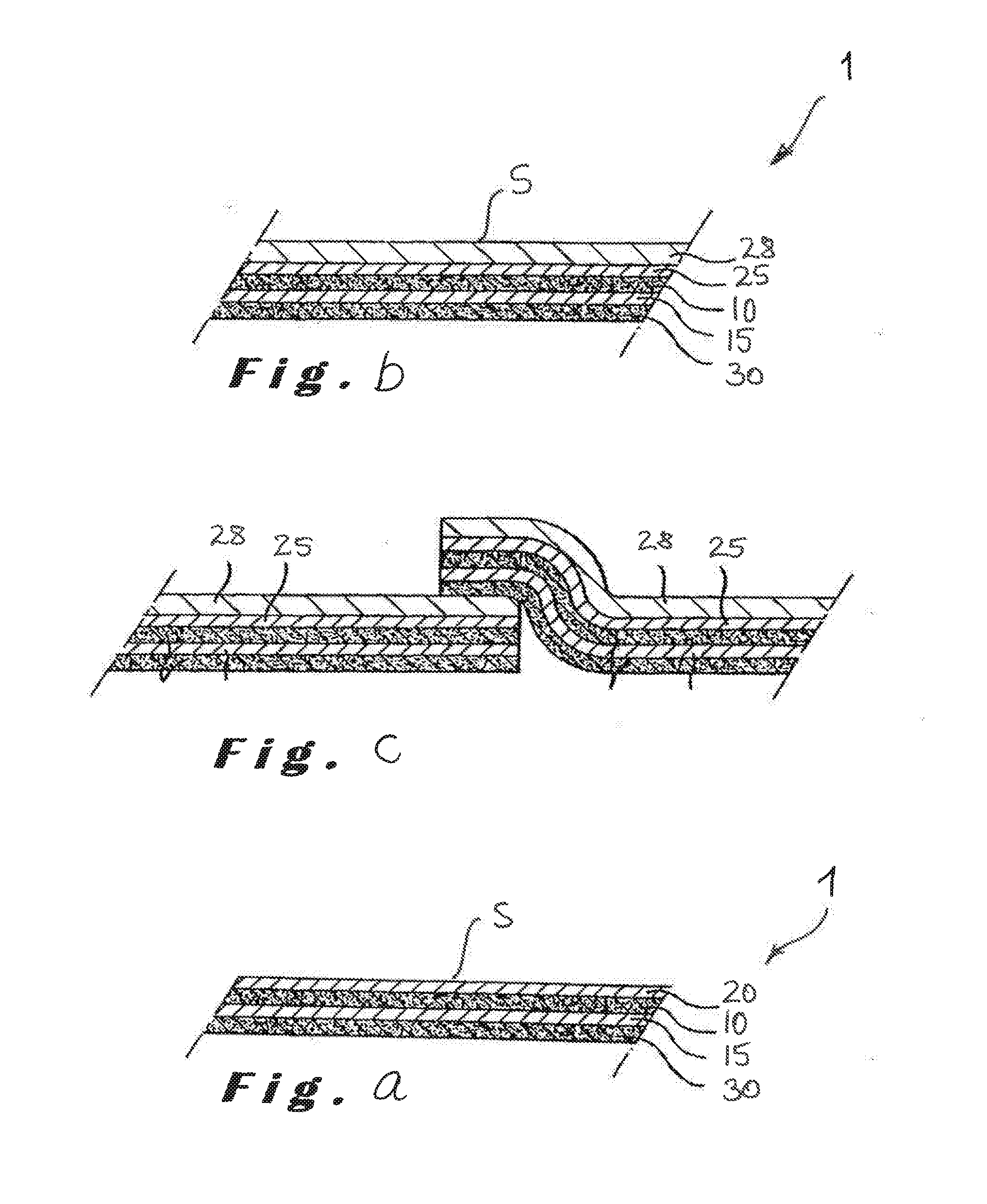

[0025]Fig. a shows a waterproofing membrane 1 comprising a structure incorporating a fibre layer 10 and carrying a bituminous mass 15 on the side to be arranged in contact with a building structure, the other side carrying a layer 20 of a substance comprising acrylic polymer mixed with titanium dioxide and a transparent or translucent hydrophobic material, the layer 20 defining the surface S of the membrane 1 that is exposed to the weather. The transparent or translucent nature of the hydrophobic material allows for the titanium dioxide pigment to be distinguishable such that the membrane appears white, the titanium dioxide giving light and heat reflective properties to the membrane. A suitable method of making the substance, also referred to in the appended claim 1 as the “first substance”, includes the steps of adding the acrylic polymer, the titanium dioxide and the hydrophobic material separately to a mixer under continued agitation.

[0026]An example of a method for applying a bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle meter | aaaaa | aaaaa |

| contact angle meter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com