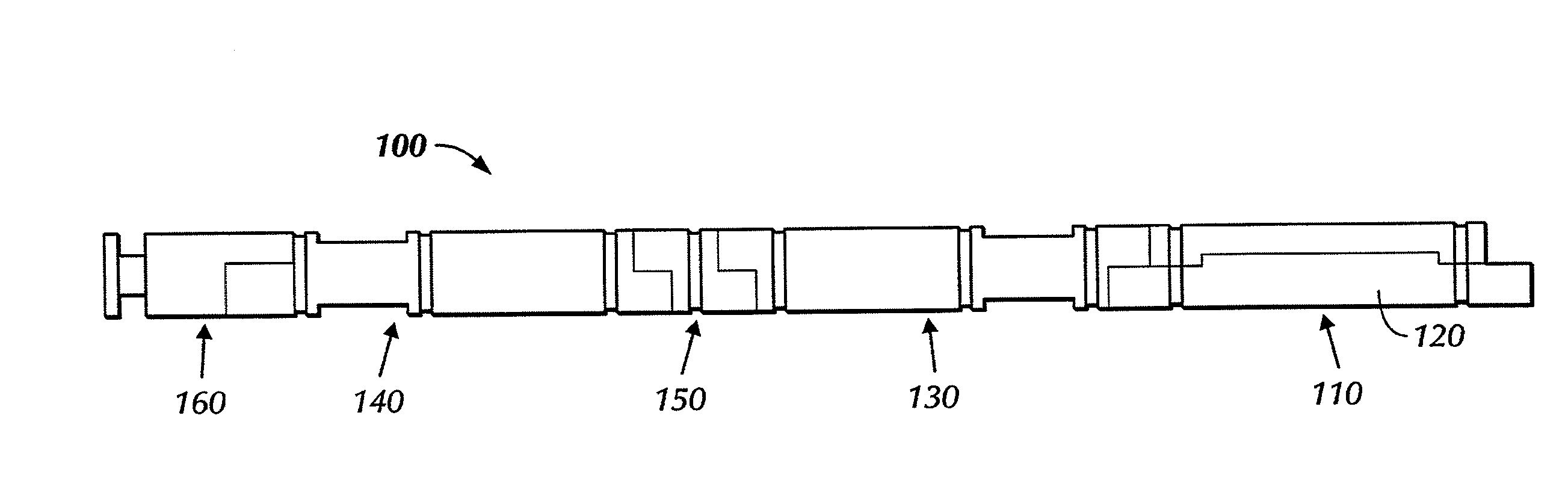

Multiple gamma controller assembly

a gamma controller and assembly technology, applied in the field of downhole radiation measurement assemblies, can solve the problems of increasing harsh environment of radiation measurement assemblies, many radiation measurement sensors are particularly sensitive and malfunction, and achieve the effect of facilitating reliable measurement of naturally occurring radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]One purpose of the improved gamma controller assembly is to increase the reliability of downhole gamma sensor measurements. One of the frequent failures in a measurement while drilling system is for the gamma probe to fail. This can be very costly to remedy as the entire drill string has to be pulled from the well to replace the gamma probe, if there is even a spare available.

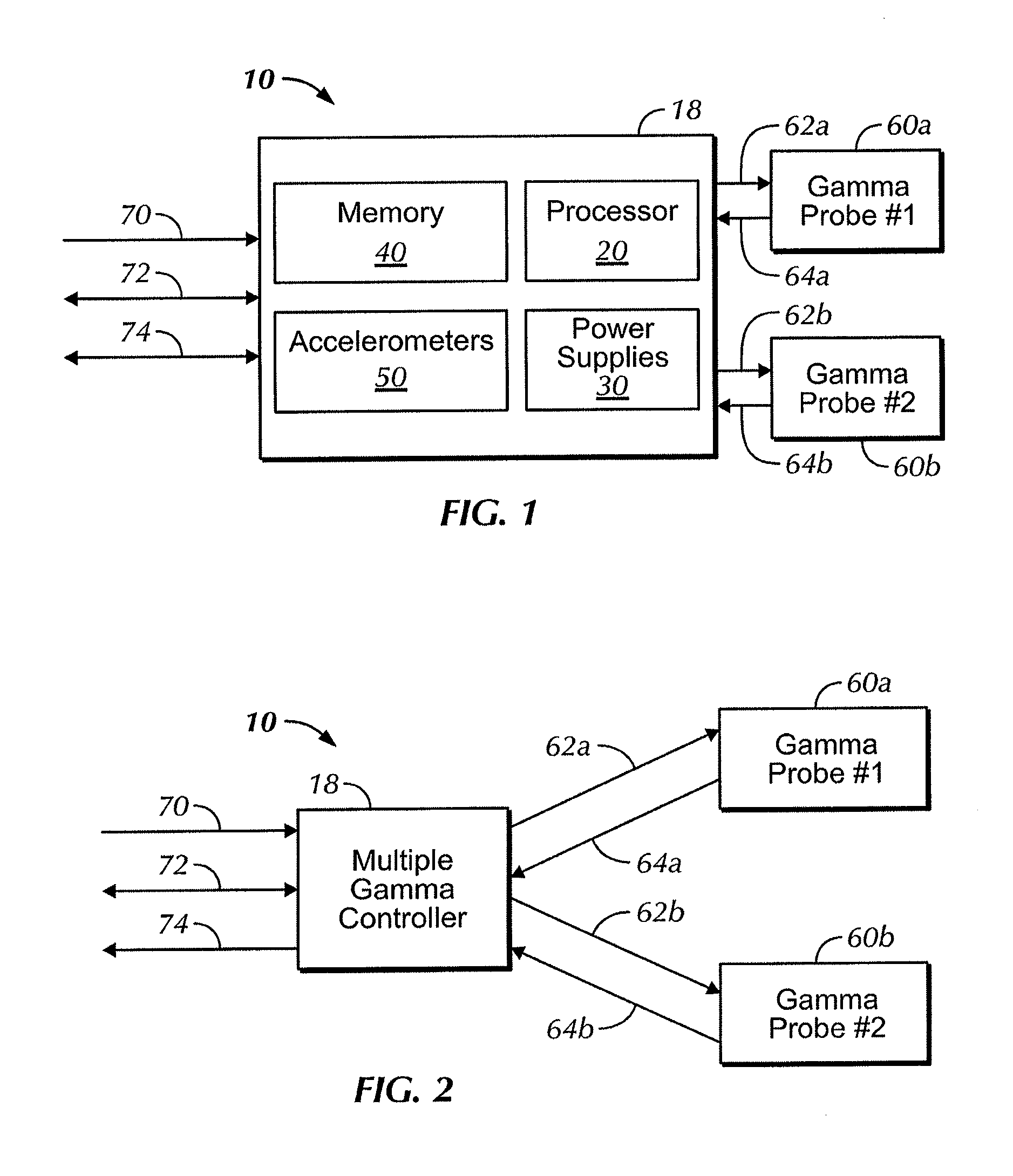

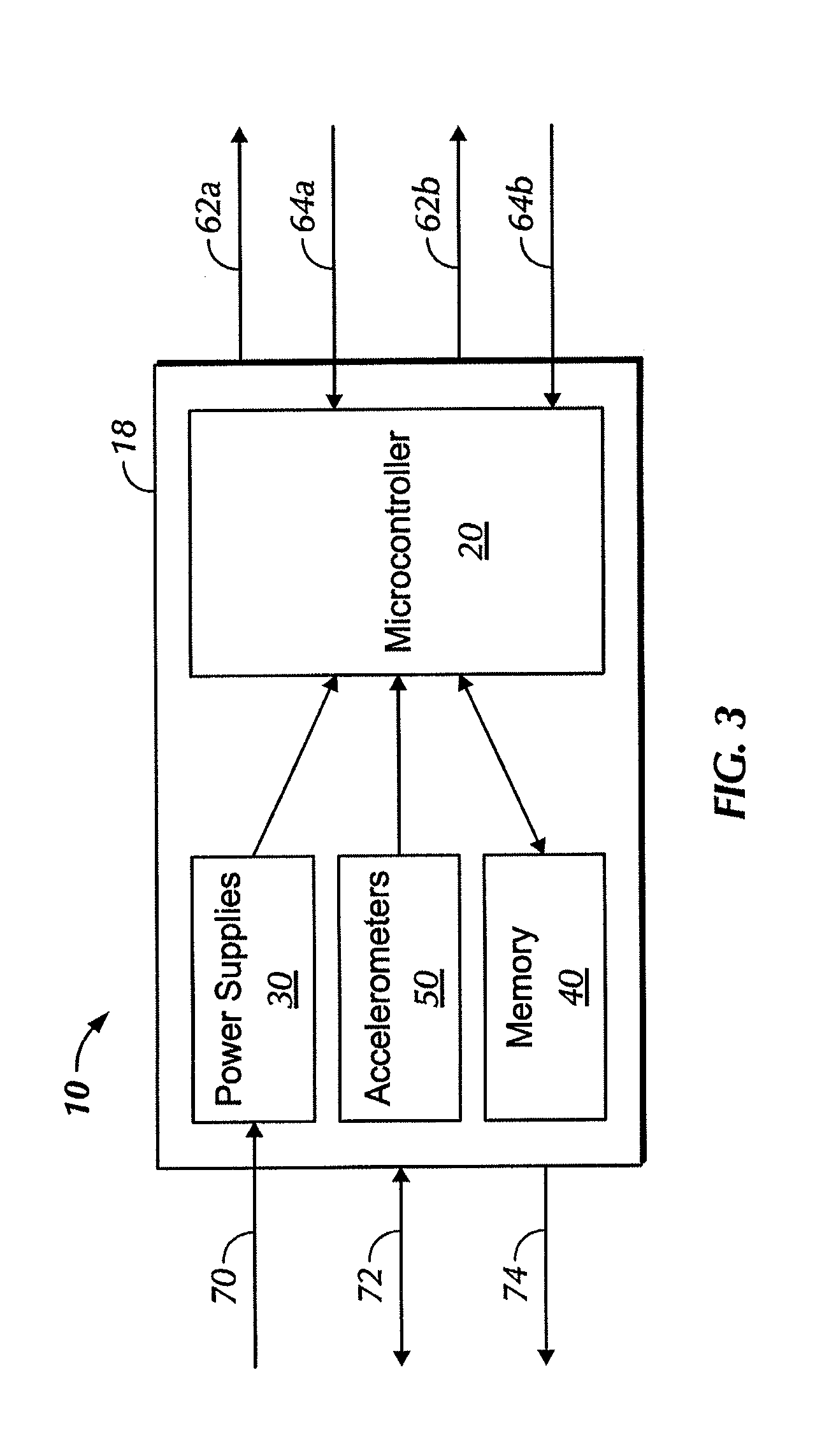

[0025]To mitigate this failure mode, the multiple gamma controller assembly facilitates redundant gamma probes in a single measurement while drilling tool. The multiple gamma controller assembly can also be configured to log various parameters of the tool downhole to assist with failure analysis when the tool is serviced. Using heuristics, if the multiple gamma controller assembly determines that each gamma probe is operating correctly, the multiple gamma controller assembly can then output a single pulse train which is a combined and filtered or alternately a single averaged reading from the multiple ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com