Method of recovering hydrocarbons from carbonate and shale formations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

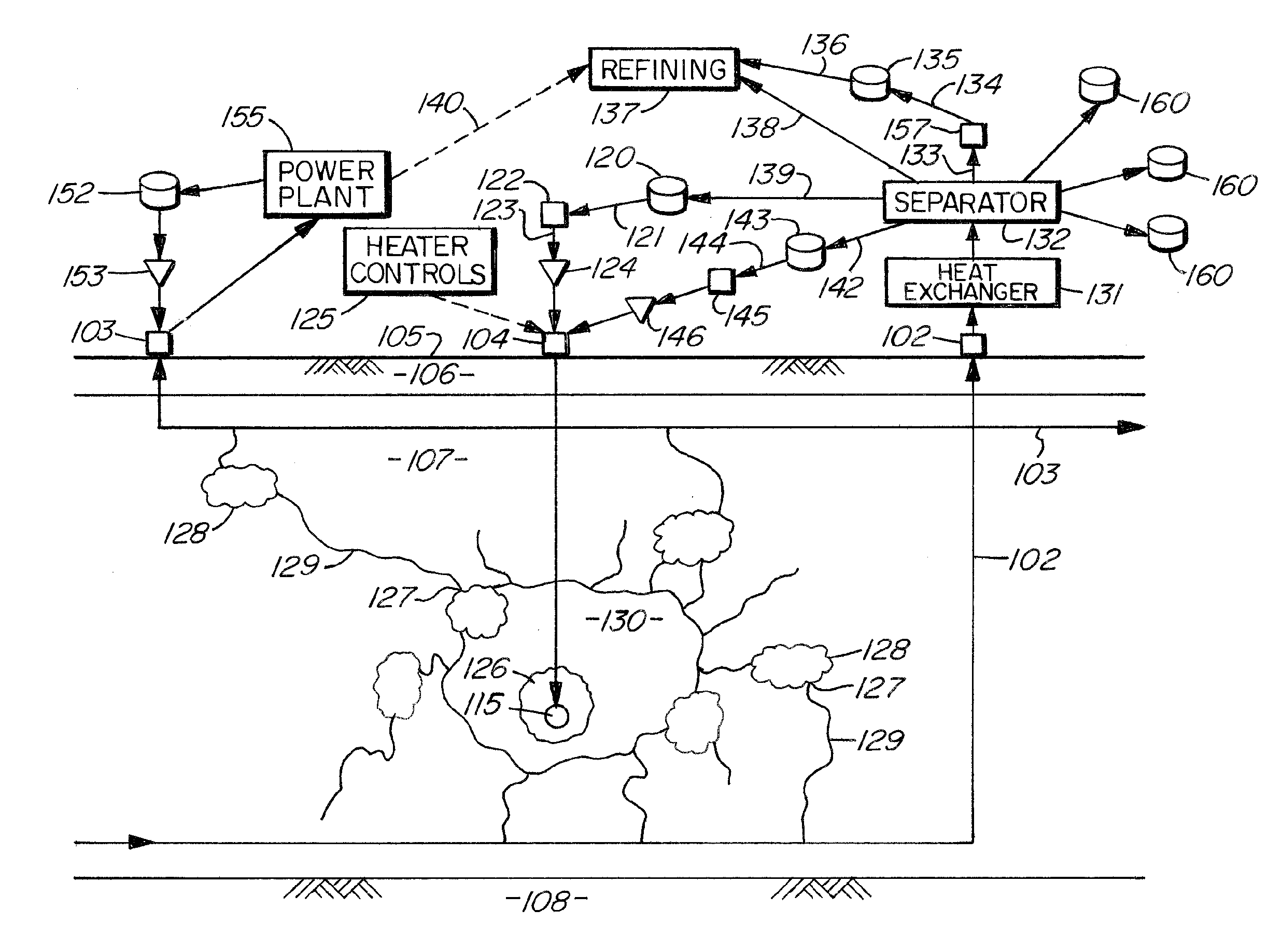

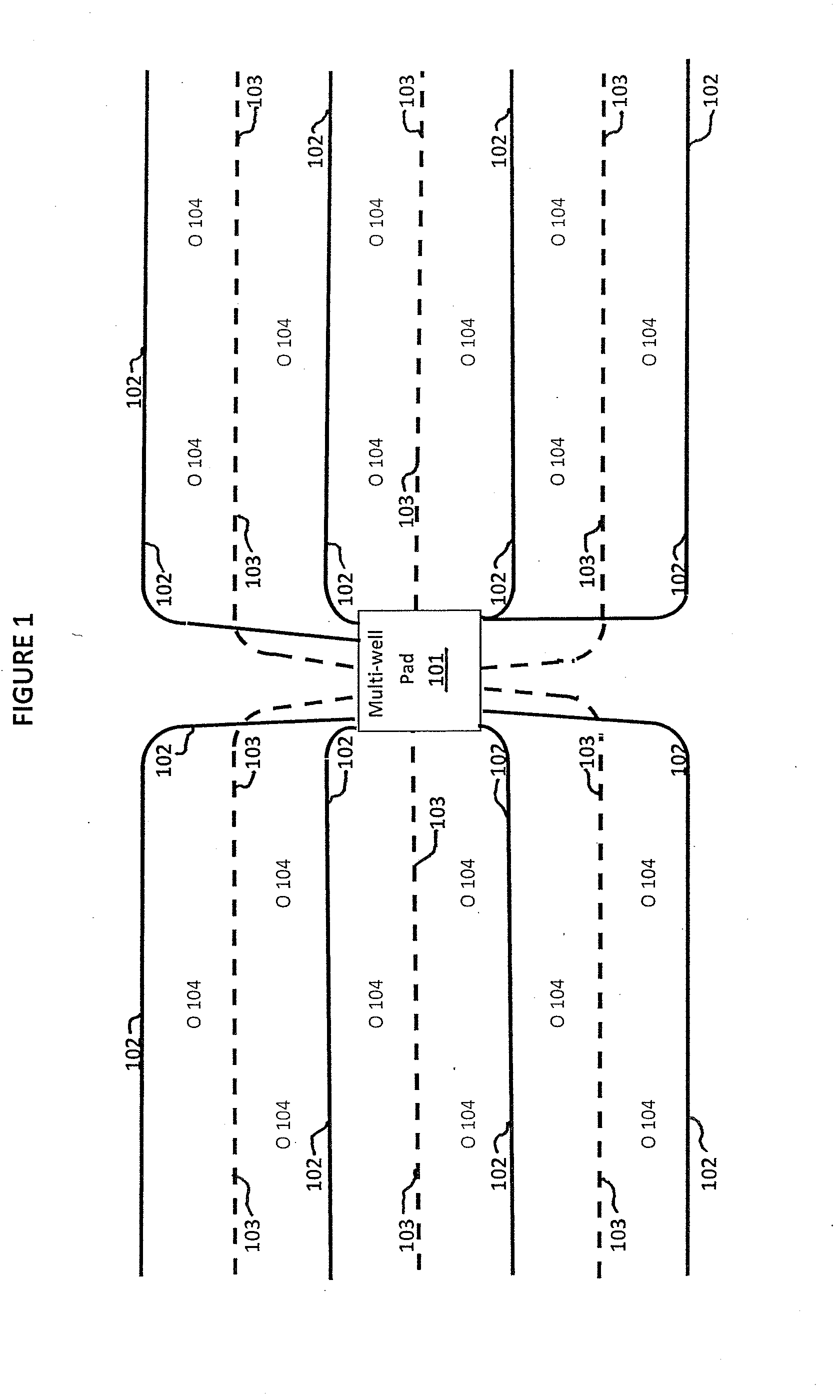

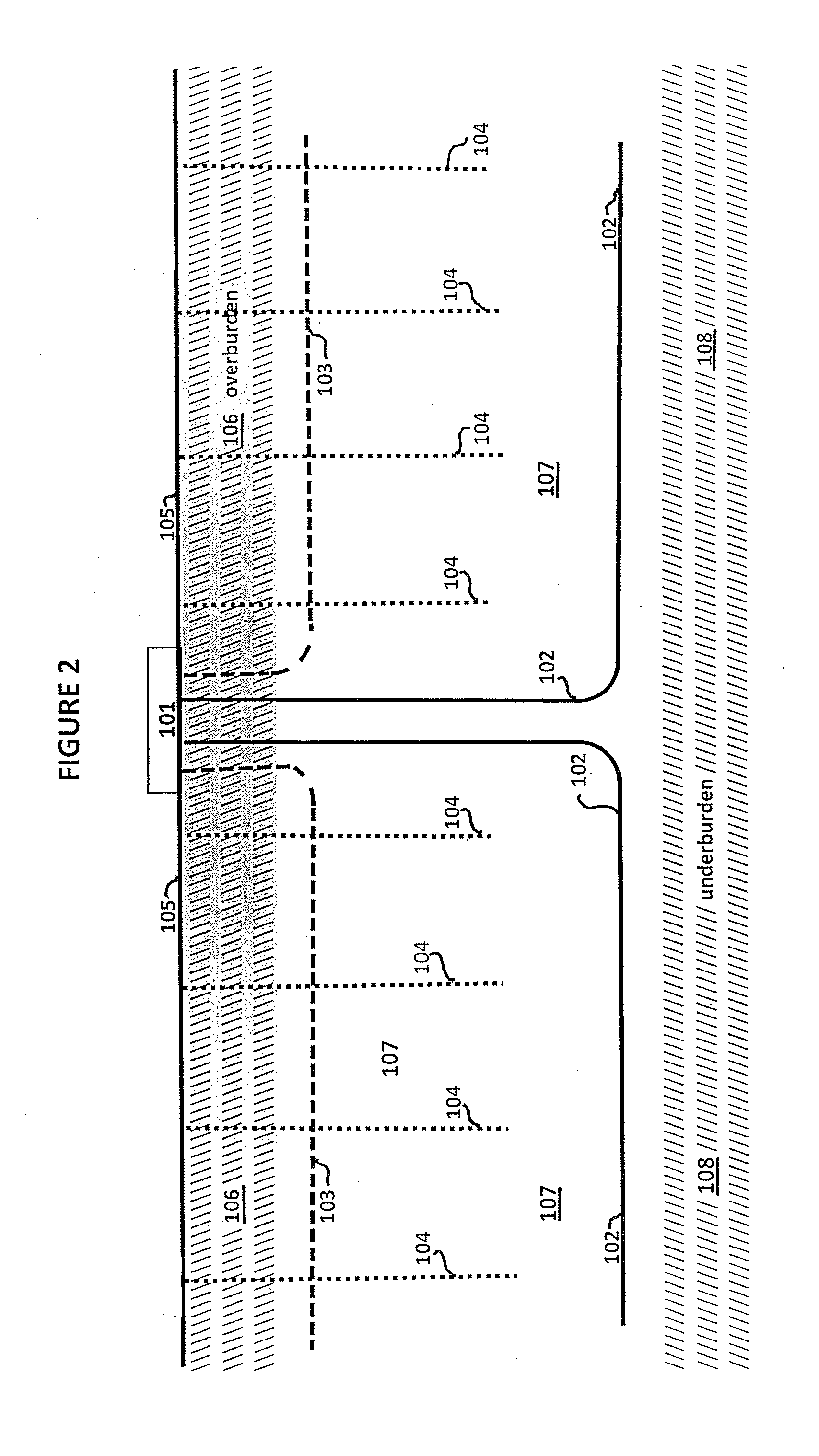

[0028]The method of the invention is based on three sets of chemical reactions occurring in situ in a subterranean formation comprised, in significant part, of silicate minerals, carbonate minerals and hydrocarbons. The reactions must be induced, but once induced the chemical reactions are complementary and self-sustaining. The method of the invention is referred to herein as the “Induced Reactions process”, and the reactions are referred to as the “induced-reactions” while they are occurring in the formation because of injections from the surface.

[0029]Once the three sets of in situ chemical reactions are self-sustaining in a formation with a mix of minerals appropriate for the Induced Reactions process, they collectively create all, or virtually all of, the permeability, heat, formation fluids and pressure necessary to mobilize hydrocarbons and drive the hydrocarbons to lower pressure production wells.

[0030]The chemistry of each of the induced-reactions is well known.

[0031]Silicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com