Trench type power transistor device

a power transistor and clamping technology, applied in the direction of semiconductor devices, basic electric elements, electrical equipment, etc., can solve the problems of lowering device performance, high miller capacitance, inevitable switching losses, etc., and achieve the effect of reducing the capacitance and switching losses of the device and improving the performance of the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

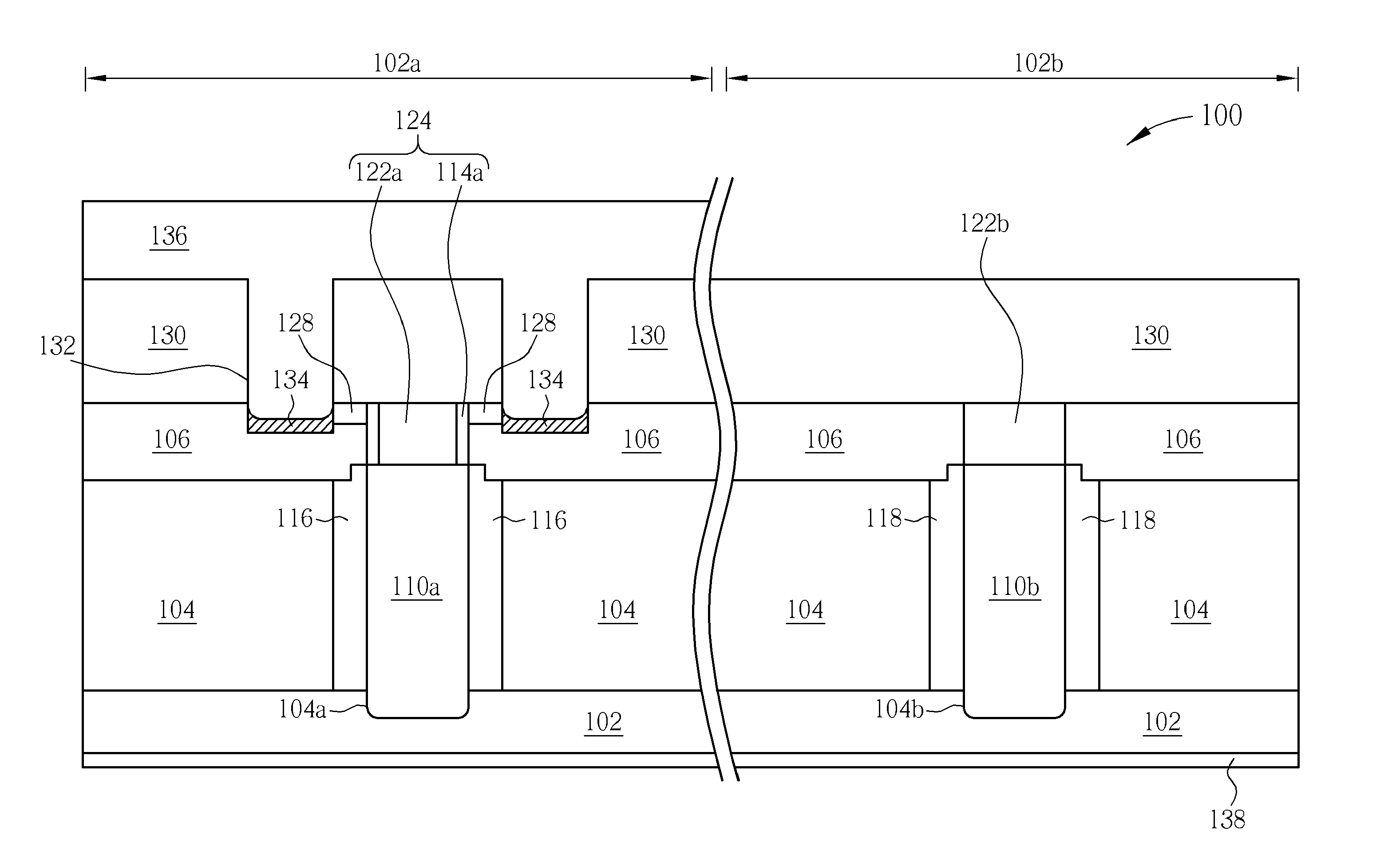

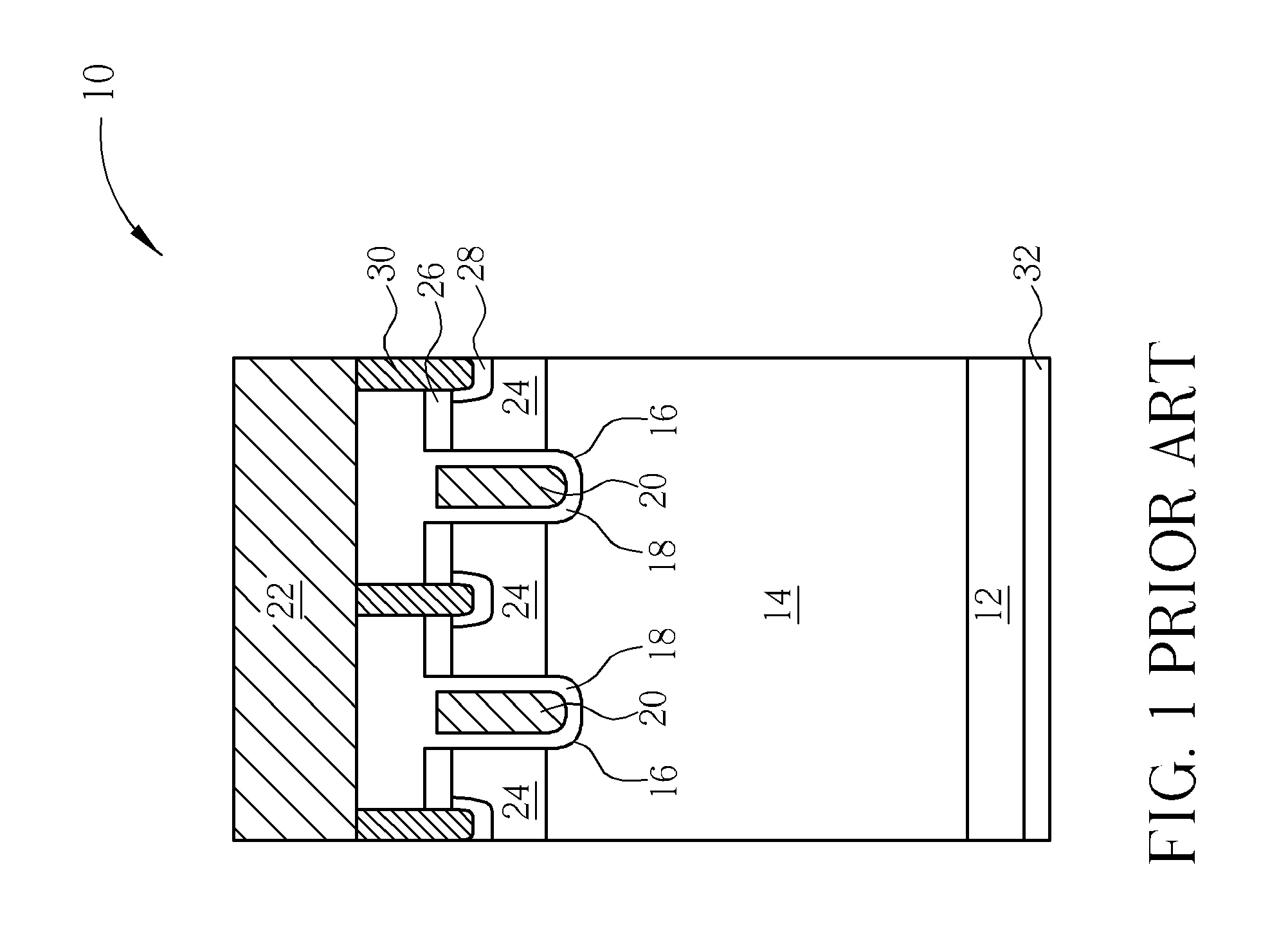

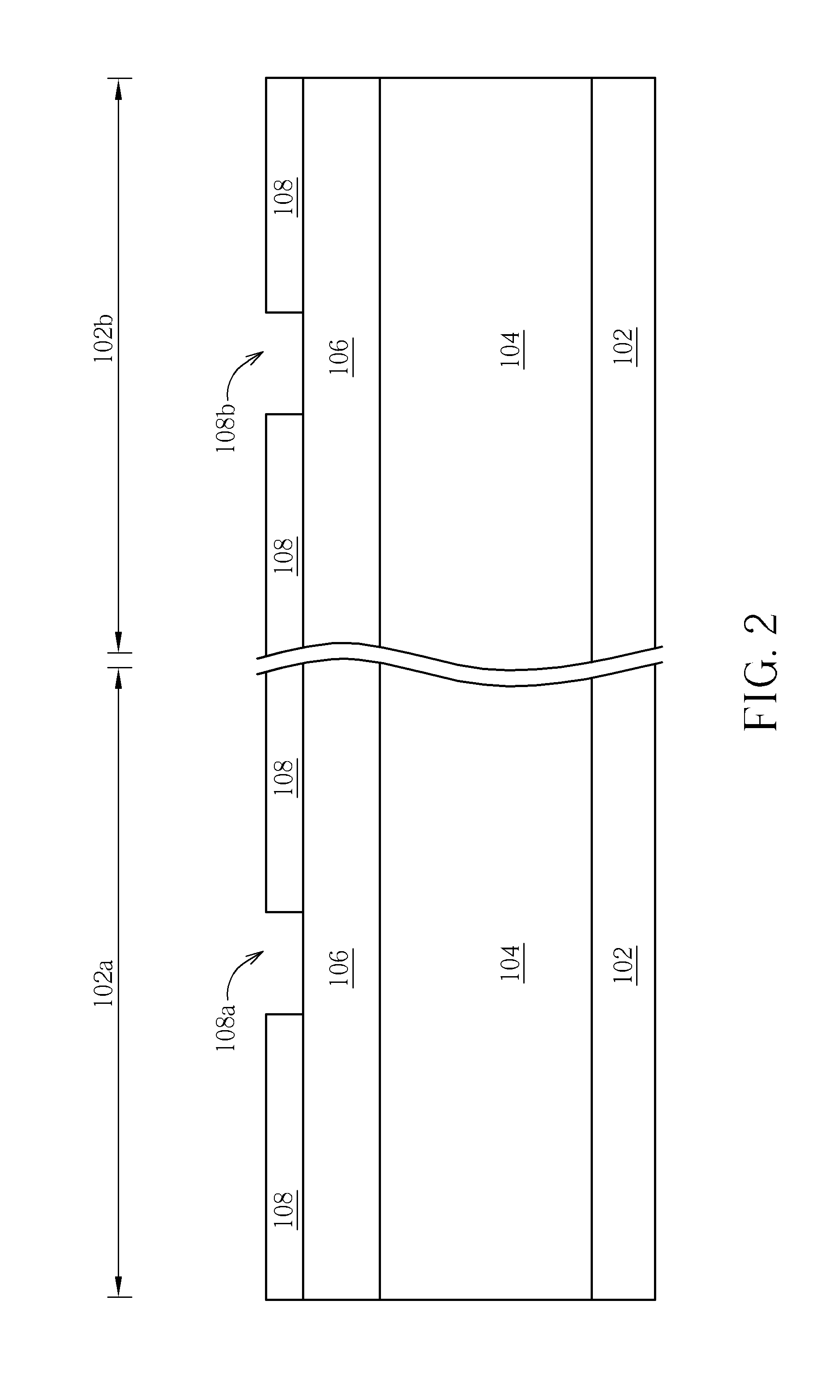

[0017]Please refer to FIG. 2 to FIG. 9. FIGS. 2-9 are schematic, cross-sectional diagrams showing a method for fabricating a trench type power transistor device according to one embodiment of the invention, wherein FIG. 9 is a schematic, cross-sectional diagram showing a structure of the trench type power transistor device. As shown in FIG. 2, a substrate 102 having a first conductivity type and having an active region 102a and a termination region 102b is provided, wherein the active region 102a is used to accommodate active devices and the termination region 102b is used to accommodate a termination structure. Then, an epitaxial layer 104 having a second conductivity type is formed on the substrate 104 through performing an epitaxial growth process, wherein the second conductivity type is different from the first conductivity type. After the formation of the epitaxial layer 104, an oxide layer (not shown) is then formed on the epitaxial layer 104 through a deposition process. With...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com