Co-axial adjustable damping assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

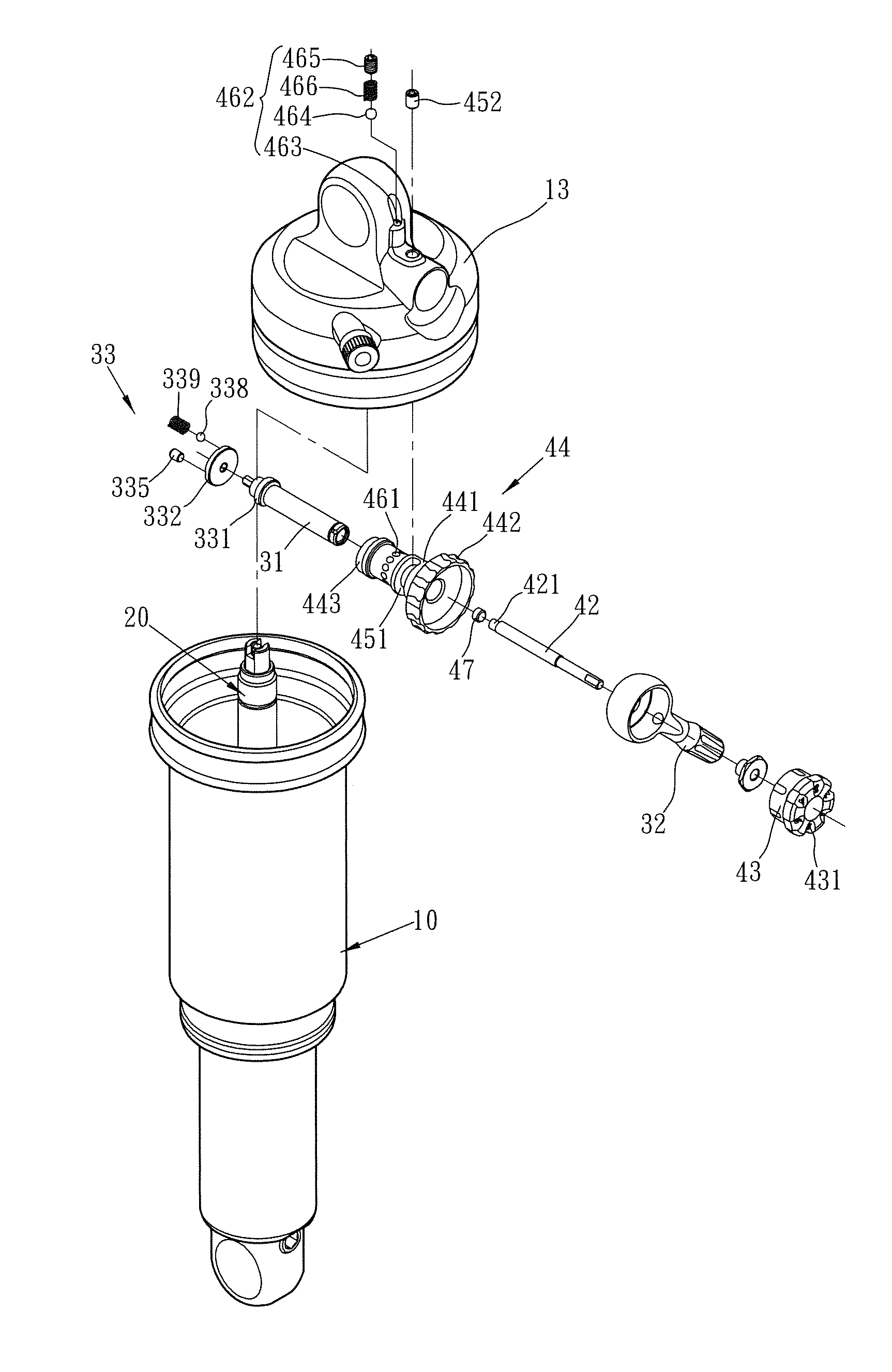

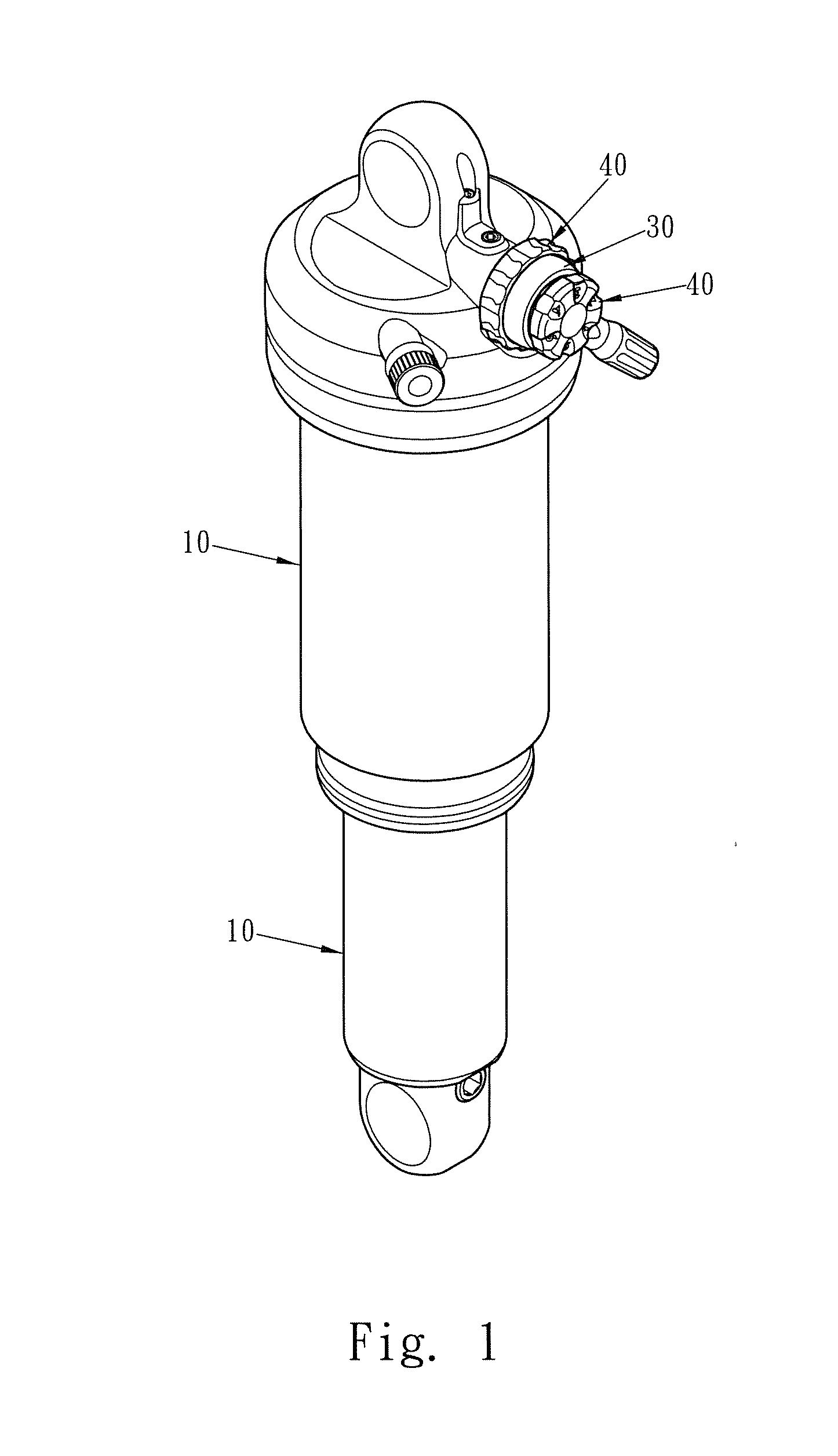

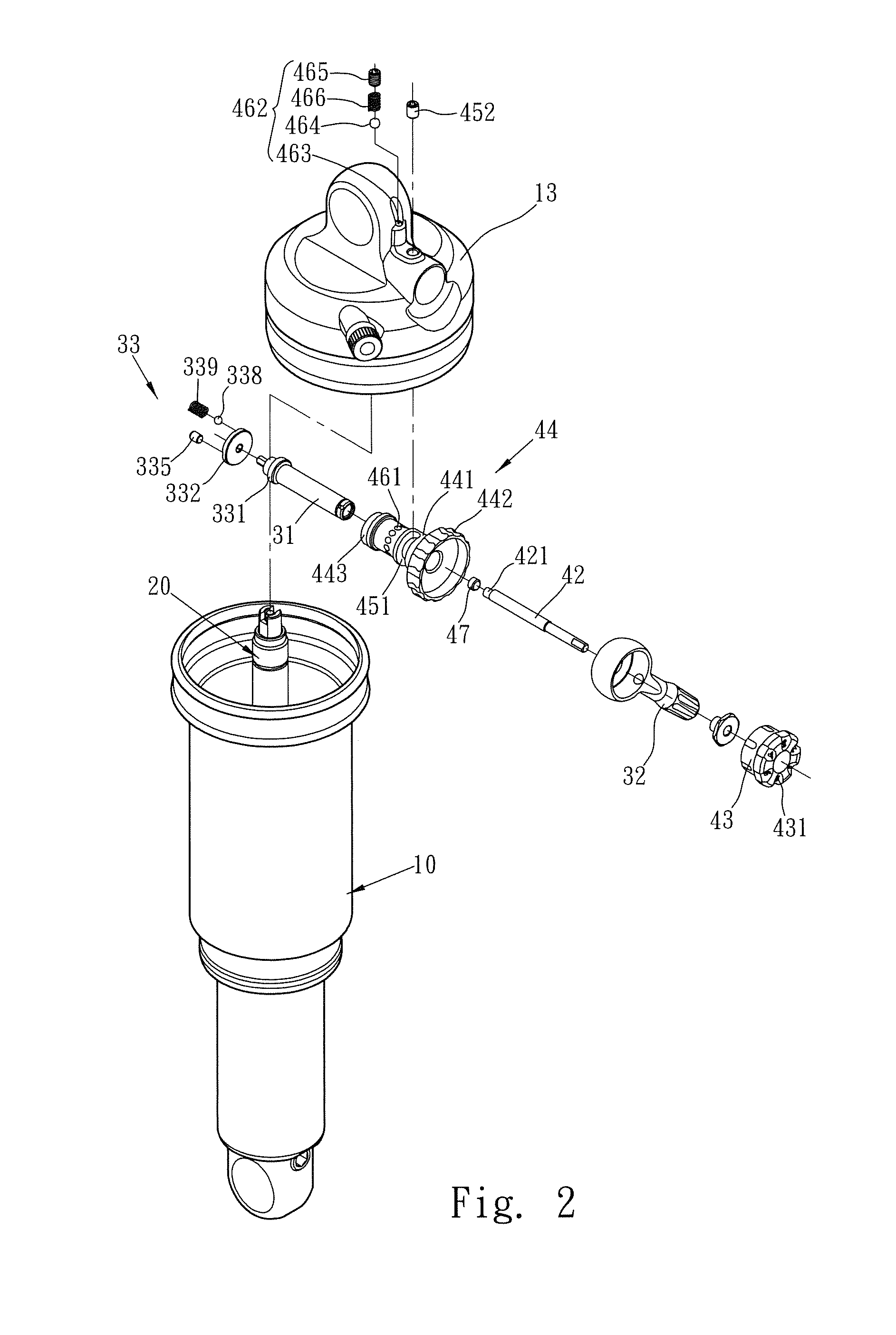

[0037]Referring to FIGS. 1 to 6, the co-axial adjustable damping assembly of the present invention comprises a cylinder unit 10, a valve unit 20 in the cylinder unit 10, a switching device 30, a damping device 40 and a pressure stabilization unit 50.

[0038]The cylinder unit 10 comprises an outer case 11 and an inner case 12 which is linearly and movably inserted into the outer case 11. The outer case 11 has a cap 13 to seal one end of the outer case 11. A piston unit 14 is connected to one end of the inner case 12 and movably in contact with inside of the outer case 11. The piston unit 14 and the inner case 12 are co-movable linearly. The piston unit 14 defines the interior of the outer case 11 into a first air chamber 111 and a second air chamber 112.

[0039]The valve unit 20 is located in the center of the outer case 11 and the first end of the valve unit 20 extends through the piston unit 14 and is inserted into the inner case 12. A piston 21 is connected to the first end of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com