Method for preparing chlorine dioxide disinfectant

A technology of chlorine dioxide and disinfectant, which is applied in the direction of chlorine dioxide, oxidized chlorine, oxidized water/sewage treatment, etc., can solve the problems of drinking water chlorite and chlorate exceeding the standard, limit, impact, etc., and achieve chlorine The effects of salt reduction, conversion rate improvement, and dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a chlorine dioxide disinfectant, comprising the following steps: separately preparing a sodium chlorite solution and a hydrochloric acid solution, adding the two together to a dosing device for an activation reaction, and continuously aerating the high Pure, highly active chlorine dioxide gas, gas purity ≥ 99%, sent to drinking water applications;

[0028] Among them, the acidity of hydrochloric acid solution is 1.1-1.18mol / L, the concentration of sodium chlorite solution is 4-5%, the reaction volume ratio of sodium chlorite solution and hydrochloric acid solution is 1:1, and the temperature of activation reaction is 21-24 °C, the activation reaction time is 15-20 minutes.

Embodiment 2

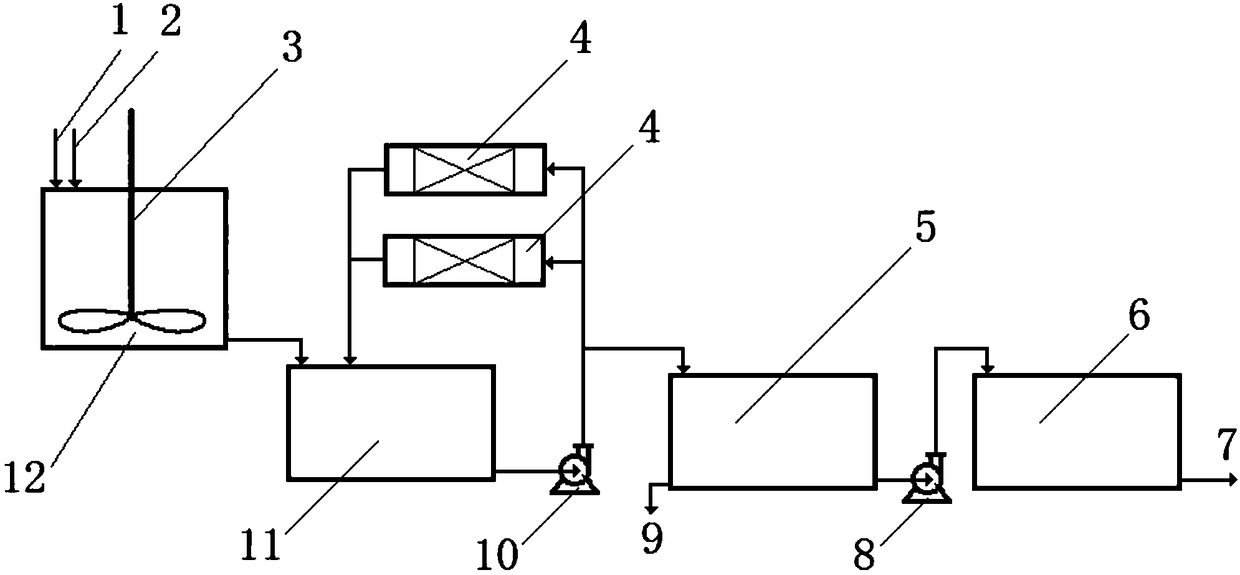

[0030] Such as figure 1 Shown, sodium chlorite solution preparation device comprises sodium chlorite dissolving tank 12, circulating dissolving tank 11, circulating pump 10, settling tank 5, conveying pump 8 and finished product tank 6 connected successively; The outlet of circulating pump 10 is connected with The first branch and the second branch, the first branch is connected with the sedimentation tank 5, the second branch is connected with the upper entrance of the circulating dissolution tank 11, and two packing filters 4 are arranged in parallel on the second branch.

[0031] On sodium chlorite dissolving tank 12, be provided with solid sodium chlorite inlet 1 and first water inlet 2, be provided with stirring device 3 in sodium chlorite dissolving tank 12; The filling port 7 is provided with a sewage outlet 9 at the bottom of the sedimentation tank 5 .

[0032]The lower part of the sodium chlorite dissolving tank 12 is connected to the upper part of the circulating di...

Embodiment 3

[0035] The method adopting the device preparation chlorine dioxide disinfectant in embodiment 2 may further comprise the steps:

[0036] Preparation and production method of sodium chlorite solution:

[0037] (1) Dissolving of solid sodium chlorite: solid sodium chlorite and process water are poured in sodium chlorite dissolving tank 12 respectively, under the mechanical stirring effect of stirring device 3, fully dissolve;

[0038] (2) sodium chlorite solution deep dissolution: the sodium chlorite solution that dissolves is put into circulation dissolving tank 11, utilizes circulation pump 10, by two parallel packing filter 4, carries out the circulation depth dissolution of solution;

[0039] (3) sodium chlorite solution precipitation: the sodium chlorite solution that will thoroughly dissolve is squeezed into the settling tank 5 with circulation pump 10 to carry out precipitation;

[0040] (4) Sodium chlorite solution (chlorine dioxide disinfectant) filling: the sodium chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com