Remediation of Sensitization in Metals

a sensitization and metal technology, applied in the field of metal sensitization remediation, can solve the problems of base metals being more susceptible to grain modification produced, and achieve the effects of effective remediation, reducing tensile stress, and reducing or eliminating substantially

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

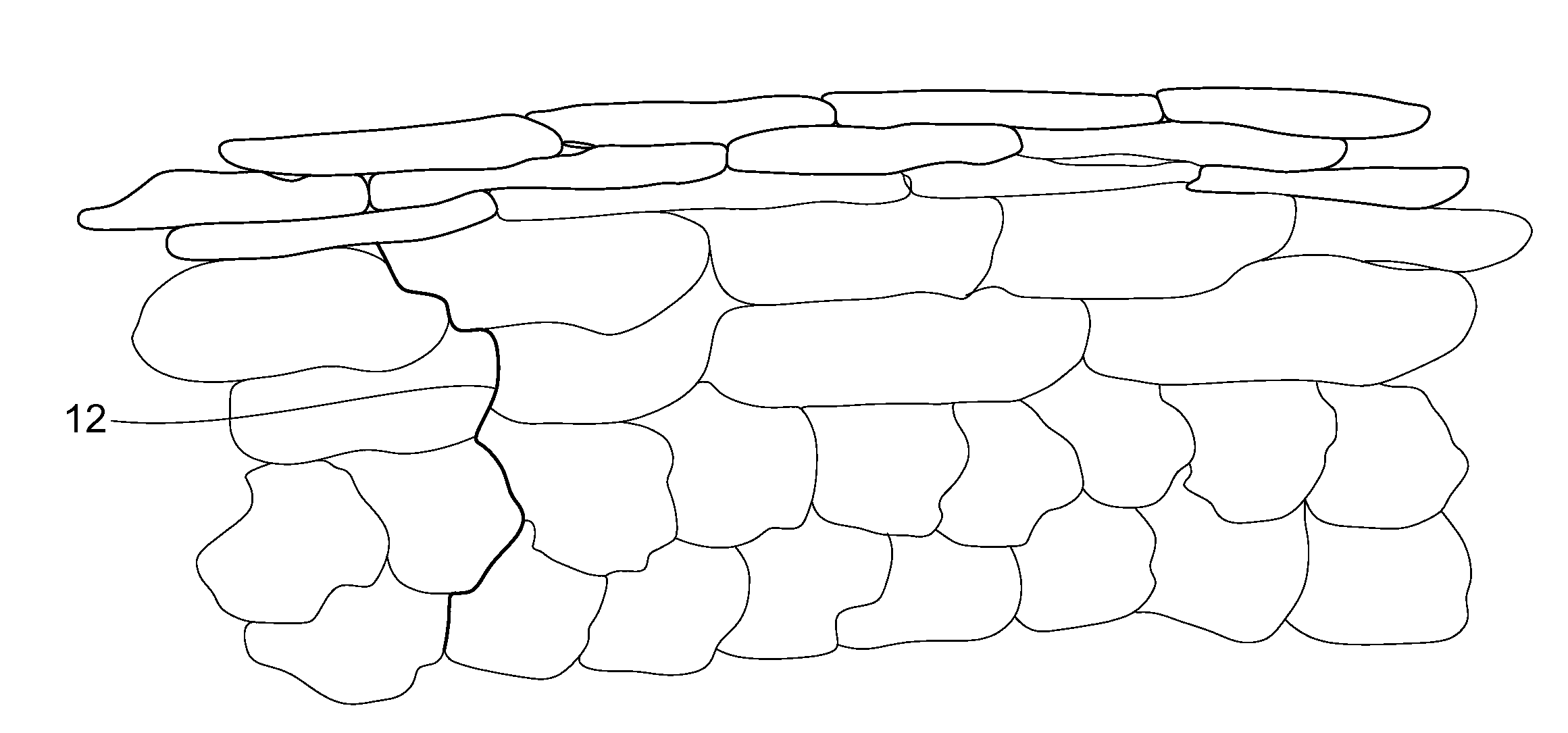

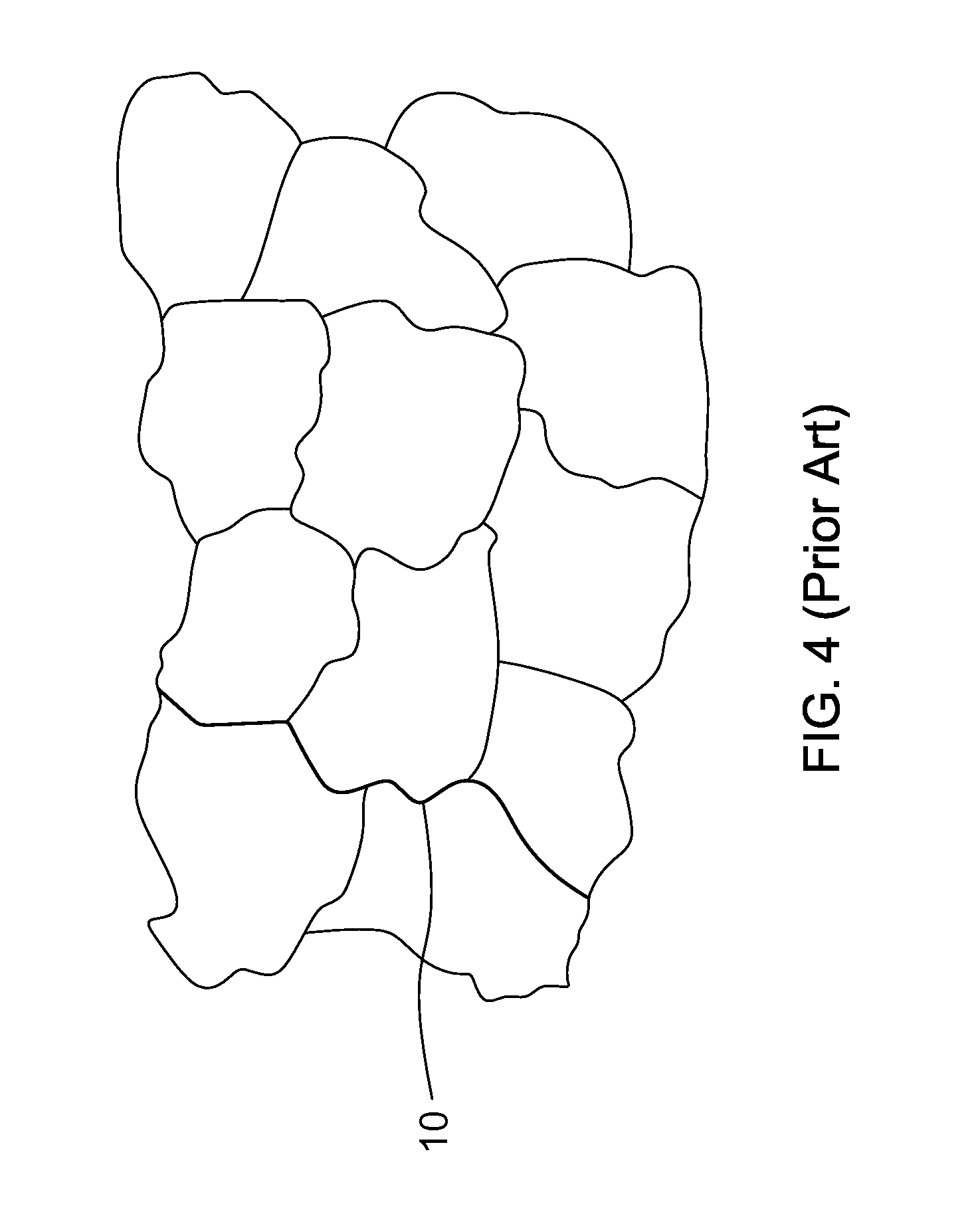

[0022]The present invention is directed to the application of UIT to sensitized metals for effectively remediating the effects of metal sensitization and / or repairing the sensitized metals using conventional and emergent welding methods. As used herein, sensitized metal refers to metal having an alloying element precipitate out of solution and congregate at the metal grain boundaries thereby forming a continuous or solid film of the alloying element along the metal grain boundaries. The film may extend to the surface of the metal. By forming a continuous or solid film, interconnected intergranular pathways are formed along the grain boundaries of the metal.

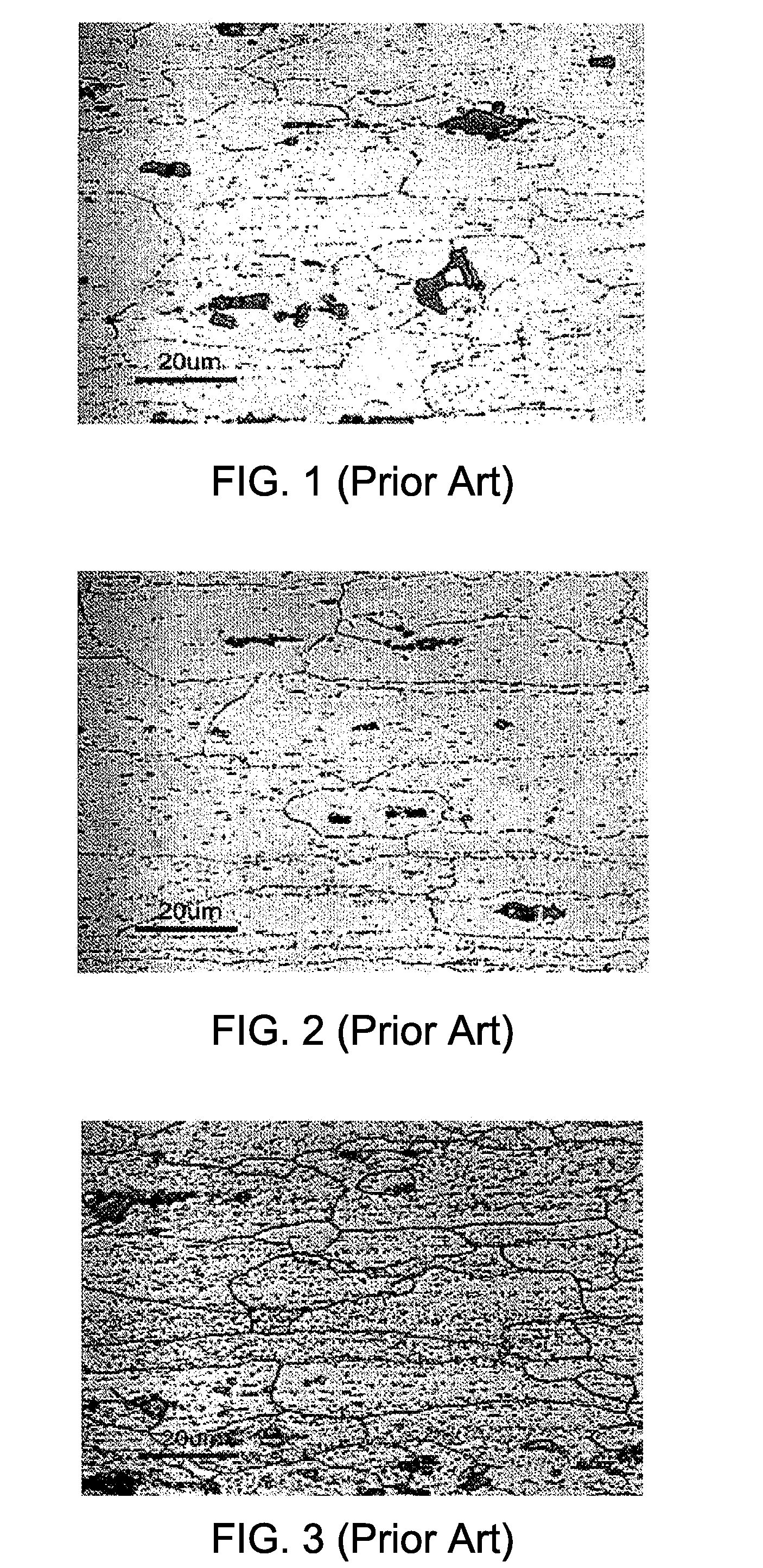

[0023]An exemplary metal that is susceptible to sensitization is 5456-H116 aluminum. 5XXX aluminum alloys are commonly used in naval ship structures. These alloys provide high strength-to-weight ratios while maintaining good as-welded strength and excellent corrosion resistance. However, alloys like 5XXX aluminum alloys with above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| ultrasonic frequencies | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com