Road basket and method of making same

a technology of road baskets and dowels, applied in the field of composite dowel baskets, can solve the problems of reducing negating the beneficial incorporation, and affecting the service life of the frame, and achieve the effect of strengthening the hold of the frame members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be described as it applies to its preferred embodiment. It is not intended that the present invention be limited to the described embodiment. It is intended that the invention cover all modifications and alternatives, which may be included within the spirit and scope of the invention.

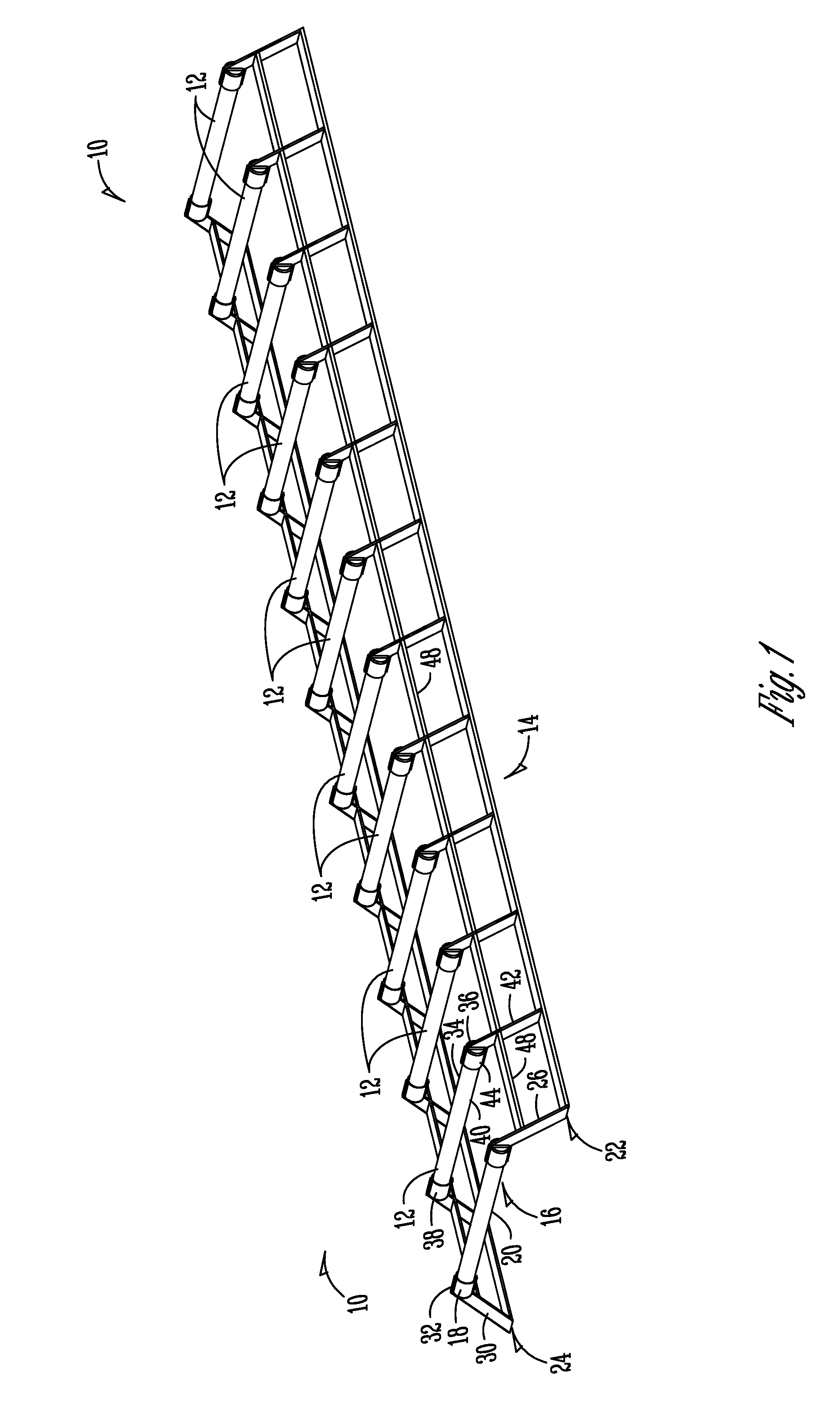

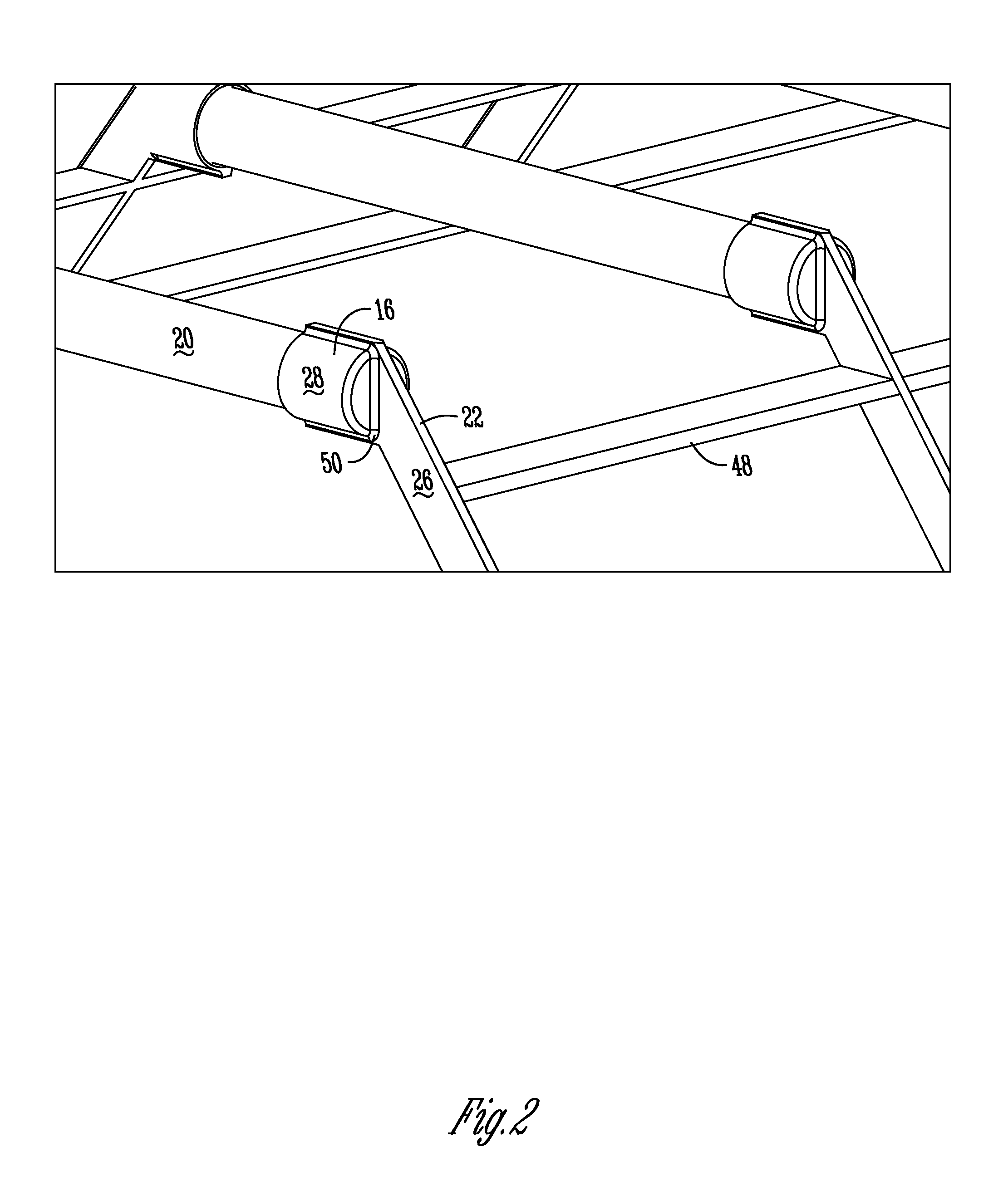

[0032]Referring to the drawings, FIG. 1 illustrates the preferred embodiment of the improved road basket 10 of the present invention. Preferably, the road basket 10 includes a plurality of non-metallic dowels 12. The dowels may be made from any desired non-corrosive material. Preferably, the dowels 12 are made from fiberglass or a glass fiber reinforced polymer that provides flexibility. The non-metallic dowels 12 are generally held in an elevated position by a frame 14.

[0033]As shown in FIGS. 1-12, the frame 14 secures multiple dowels parallel to each other and parallel to the ground simplifying installation of the dowels in a slip form paving process. Preferably, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com