Semiconductor device and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0083]In this embodiment, a semiconductor device of one embodiment of the present invention is described with reference to drawings.

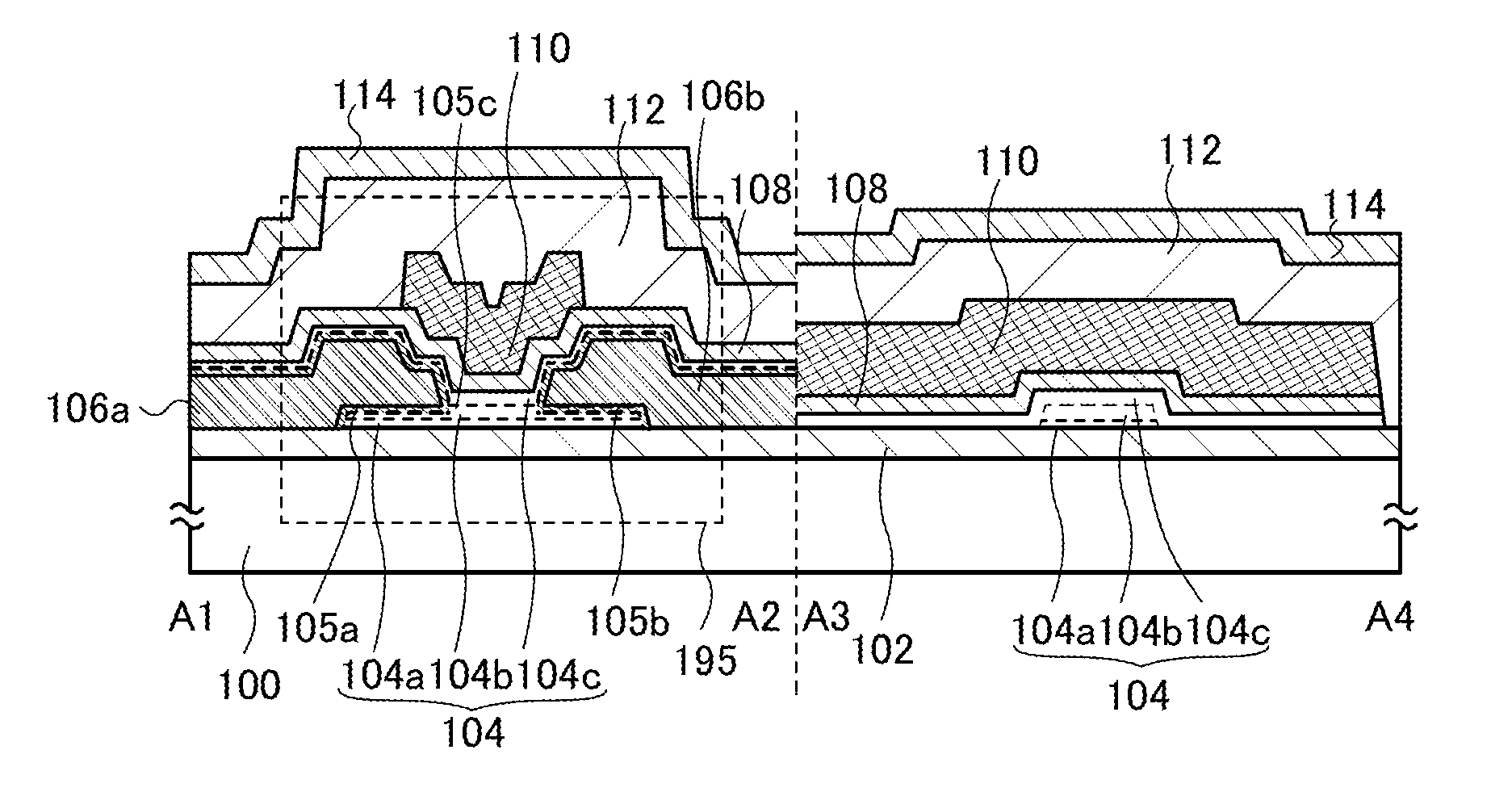

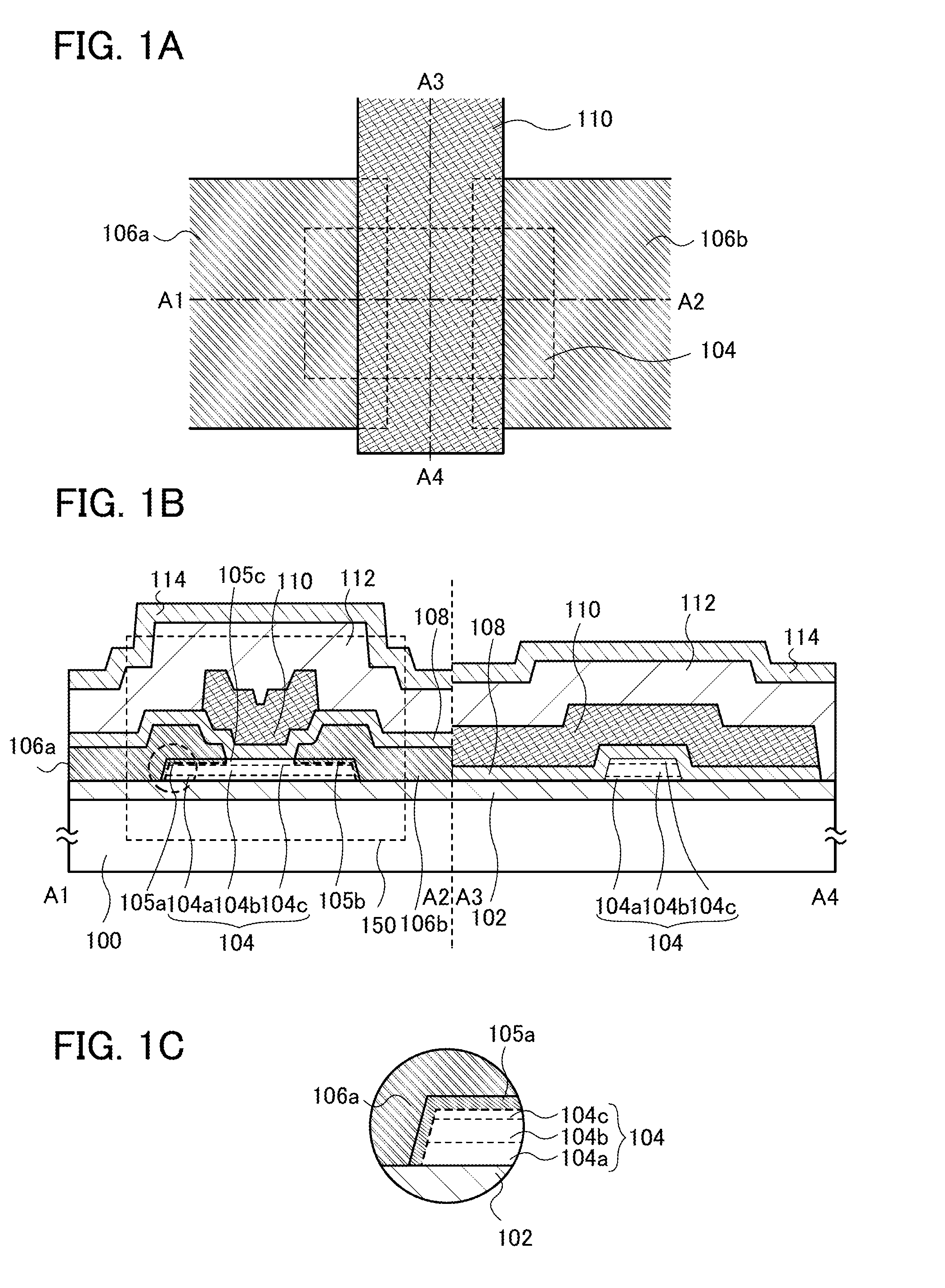

[0084]FIGS. 1A to 1C are a top view and cross-sectional views illustrating a transistor of one embodiment of the present invention. FIG. 1A is the top view, and a cross section taken along a dashed-dotted line A1-A2 and a dashed-dotted line A3-A4 in FIG. 1A corresponds to FIG. 1B. FIG. 1C is an enlarged view of a region surrounded by a circle of a dotted line in FIG. 1B. Note that some components in the top view in FIG. 1A are not illustrated for simplification of the drawing.

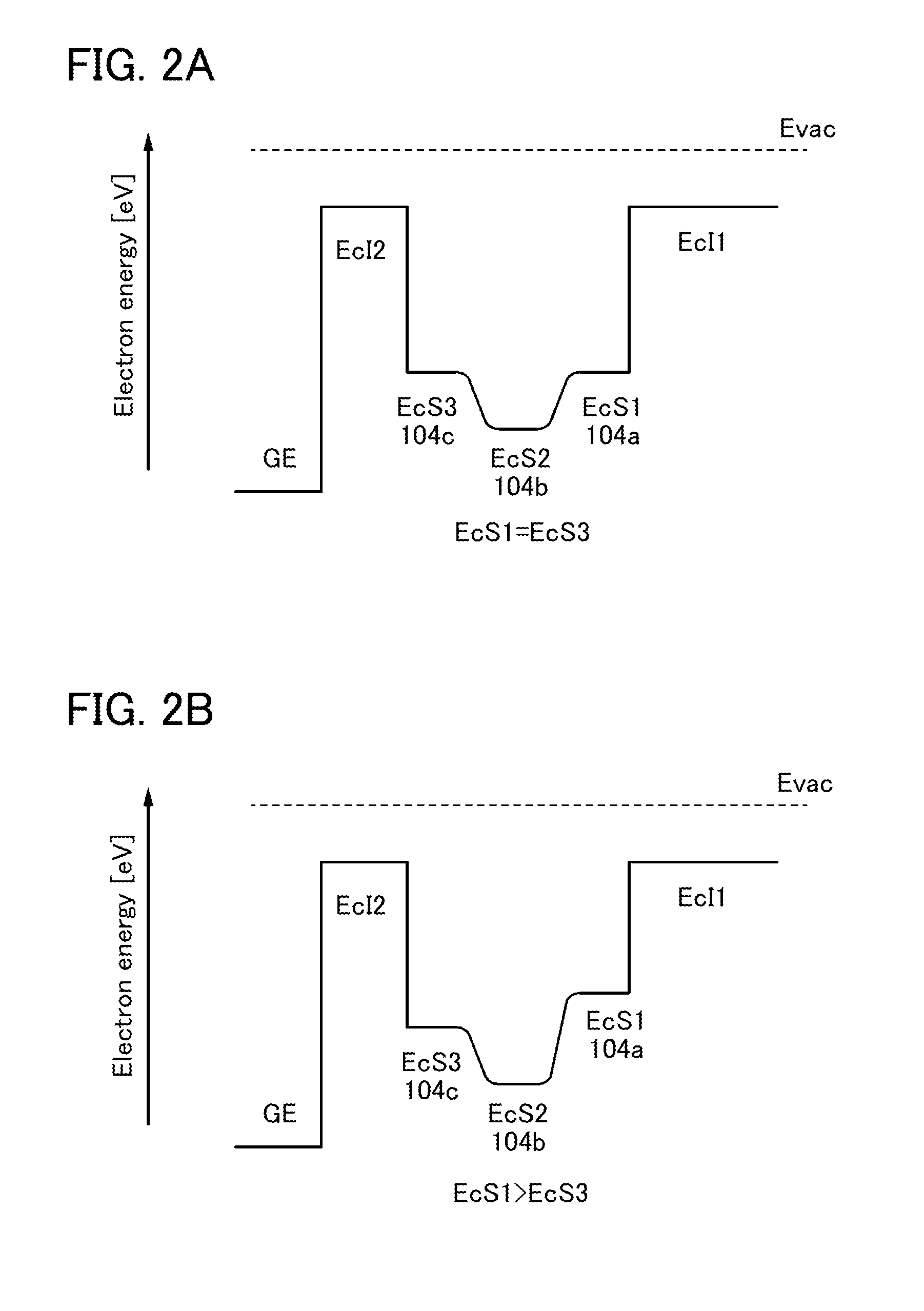

[0085]A transistor 150 illustrated in FIGS. 1A to 1C includes a base insulating film 102 over a substrate 100; a multilayer film 104 including an oxide semiconductor film over the base insulating film 102; a low-resistance region 105a and a low-resistance region 105b over the multilayer film 104; a source electrode 106a over the low-resistance region 105a; a drain electrode 106b ov...

embodiment 2

[0208]In this embodiment, a method for manufacturing the transistor 150 described in Embodiment 1 with reference to FIGS. 1A to 1C is described.

[0209]First, the base insulating film 102 is formed over the substrate 100.

[0210]A glass substrate, a ceramic substrate, a quartz substrate, a sapphire substrate, or the like can be used as the substrate 100. Alternatively, a single crystal semiconductor substrate or a polycrystalline semiconductor substrate made of silicon, silicon carbide, or the like, a compound semiconductor substrate made of silicon germanium or the like, a silicon-on-insulator (SOI) substrate, or the like may be used. Still alternatively, any of these substrates further provided with a semiconductor element may be used.

[0211]The base insulating film 102 can be formed by a plasma chemical vapor deposition (CVD) method, a sputtering method, or the like using an oxide insulating film of aluminum oxide, magnesium oxide, silicon oxide, silicon oxynitride, gallium oxide, ger...

embodiment 3

[0297]In this embodiment, a transistor having a structure different from that of the transistor described in Embodiment 1 is described.

[0298]FIGS. 10A to 10C are a top view and cross-sectional views of a transistor of one embodiment of the present invention. FIG. 10A is a top view, and a cross section taken along a dashed-dotted line B1-B2 and a dashed-dotted line B3-B4 in FIG. 10A is illustrated in FIG. 10B. FIG. 10C is an enlarged view of a region surrounded by a dashed-line circle in FIG. 10B. Note that for simplification of the drawing, some components in the top view in FIG. 10A are not illustrated.

[0299]A transistor 250 illustrated in FIGS. 10A to 10C includes: the gate electrode 110 over the substrate 100; the gate insulating film 108 over the gate electrode 110; the multilayer film 104 over the gate insulating film 108; the low-resistance region 105a and the low-resistance region 105b over the multilayer film 104; the source electrode 106a over the low-resistance region 105a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com