Method for reducing flue gas carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

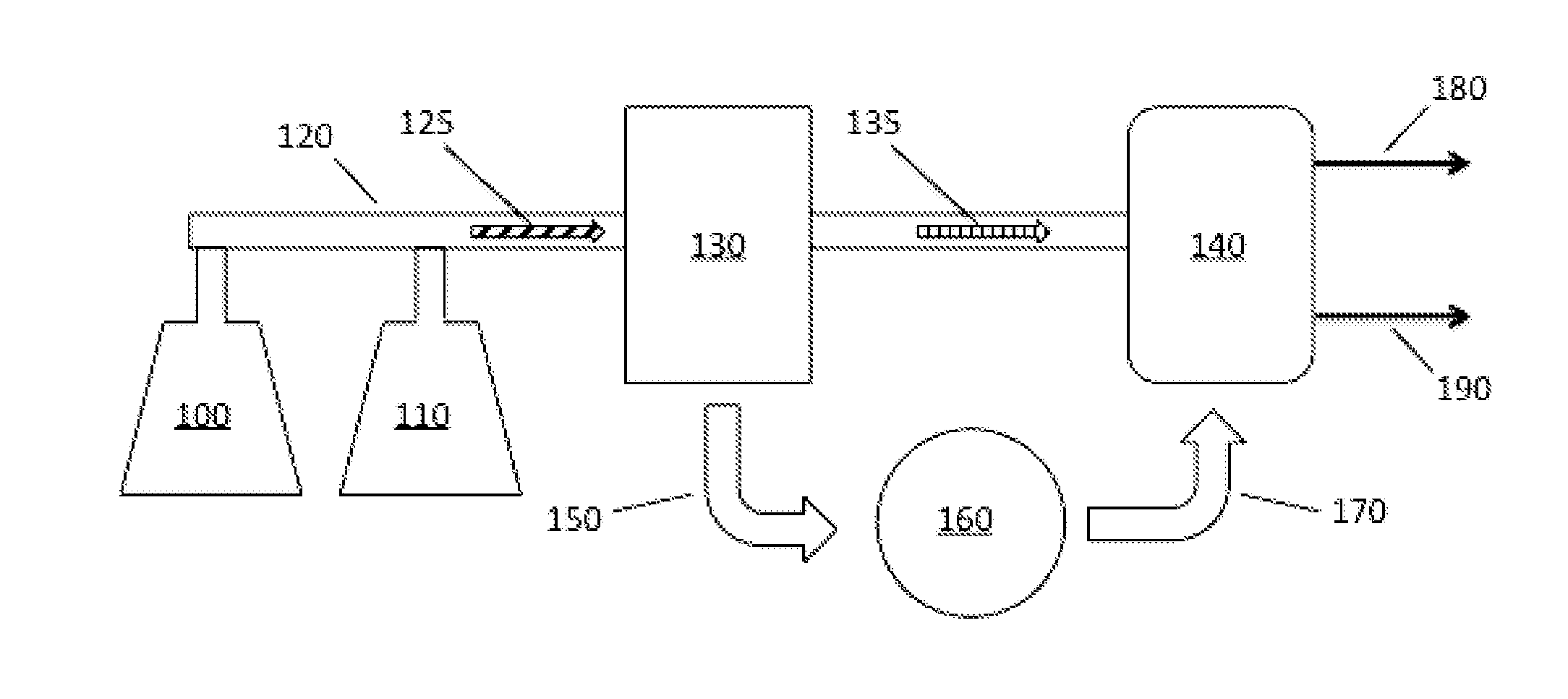

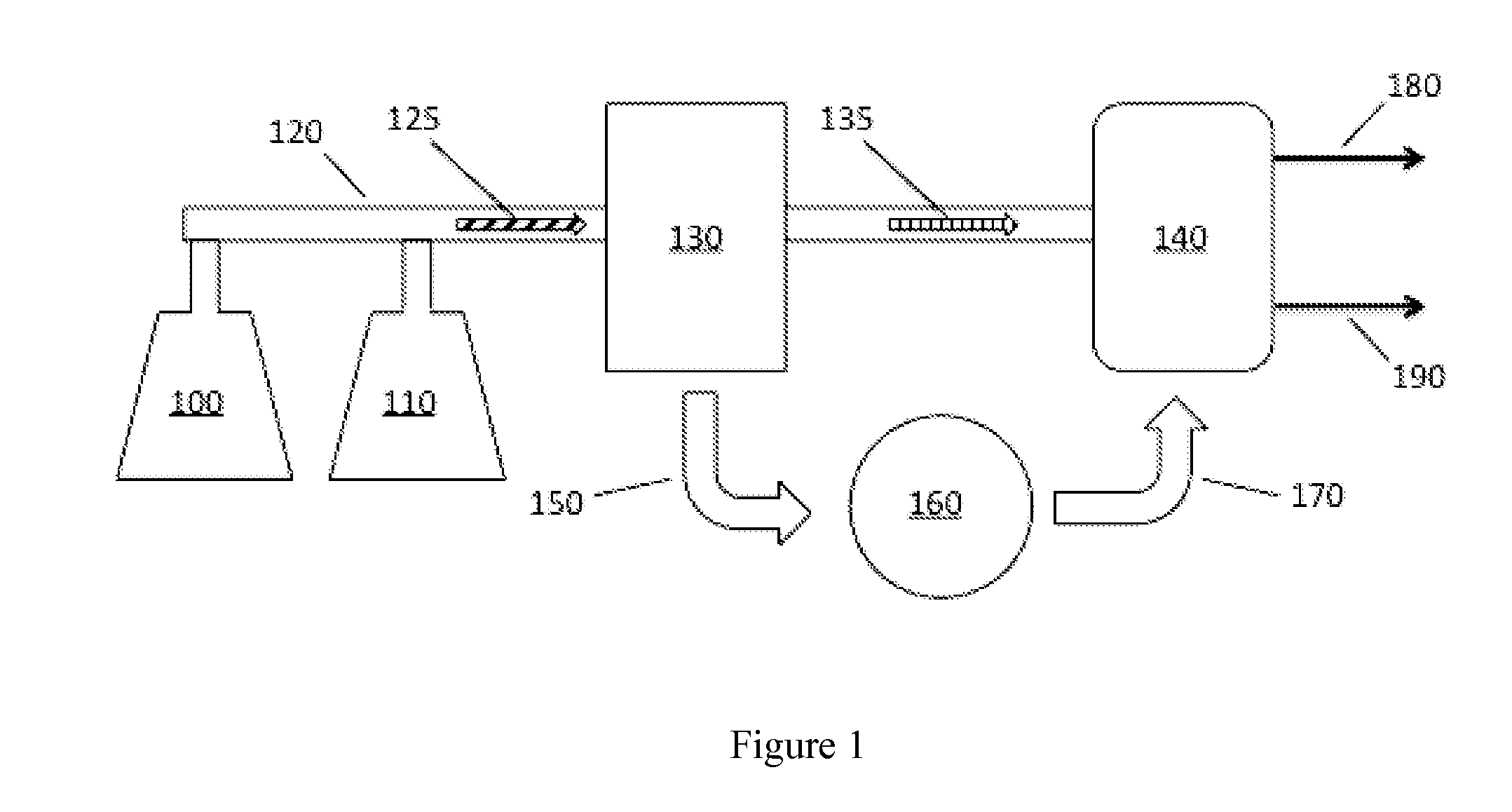

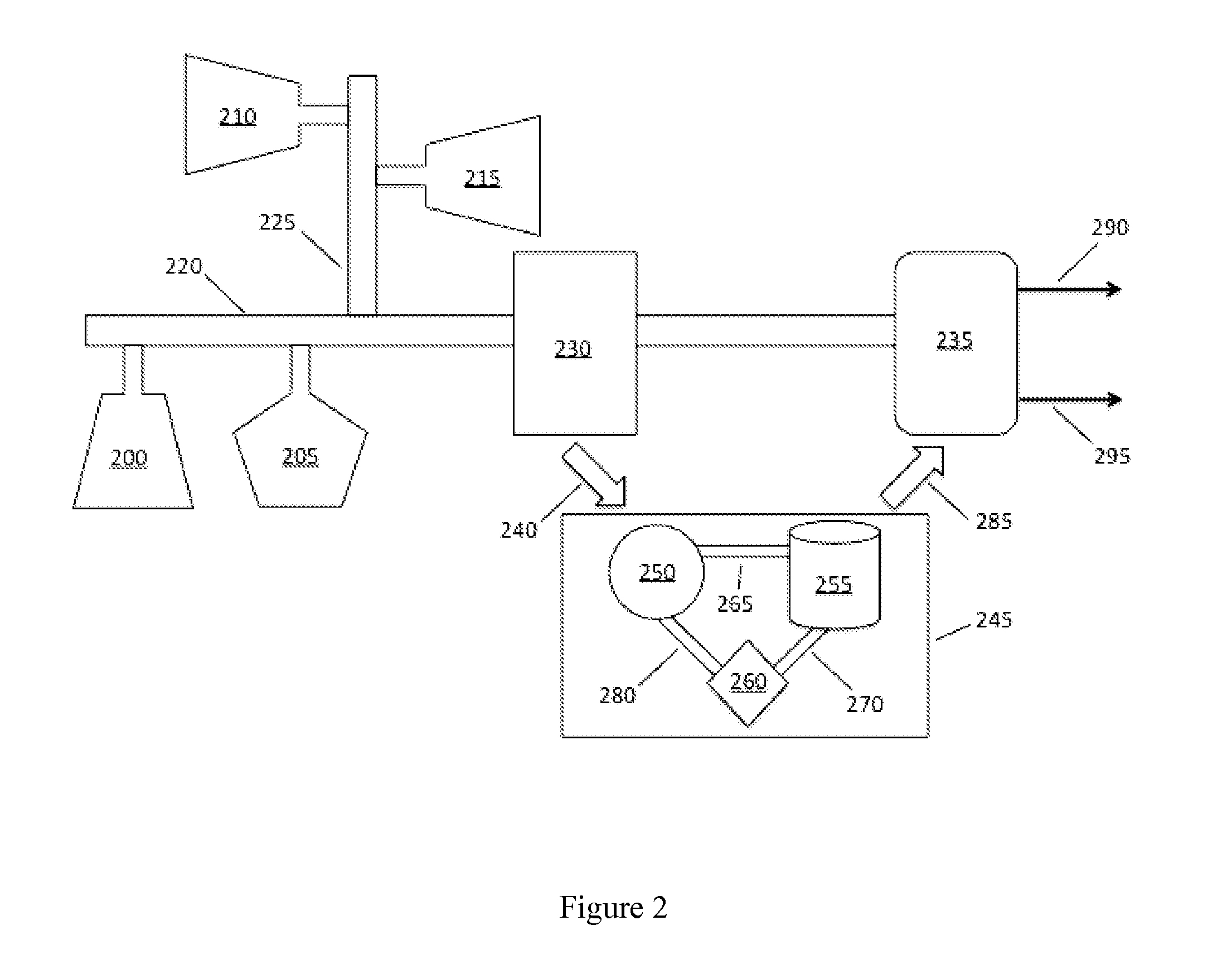

Image

Examples

Embodiment Construction

[0012]It should be noted that while the following description is drawn to methods and devices for efficiently recovering CO2 from flue gas, various alternative configurations are also deemed suitable and may be employed to treat any suitable source of CO2 containing gas streams, such as streams from combustion processes in the oil and gas industry, cement plants, lime kiln exhausts, engine exhausts, fermentation processes, hydrogen production plants, ammonia production plants, processing of phosphates, and so on. One should appreciate that compounds other than CO2 may be recovered, including (but not limited to) CO, ammonia, nitrogen oxides, sulfur oxides, volatile organic carbon compounds, and chlorofluorocarbons, from gas streams containing such compounds.

[0013]One should appreciate that the disclosed techniques provide many advantageous technical effects including providing energy efficient recovery of CO2 from flue gas, permitting CO2 to be sequestered and thereby preventing it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com