Spindle motor having a low overall height

a spindle motor and overall height technology, which is applied in the direction of sliding contact bearings, instruments, record information storage, etc., can solve the problems of not being able to achieve the required holding power between the components, and the capillary sealing gap needs sufficient space, so as to reduce not impair the stability of the bearing and the function. , to achieve the effect of reducing the overall height of the spindle motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

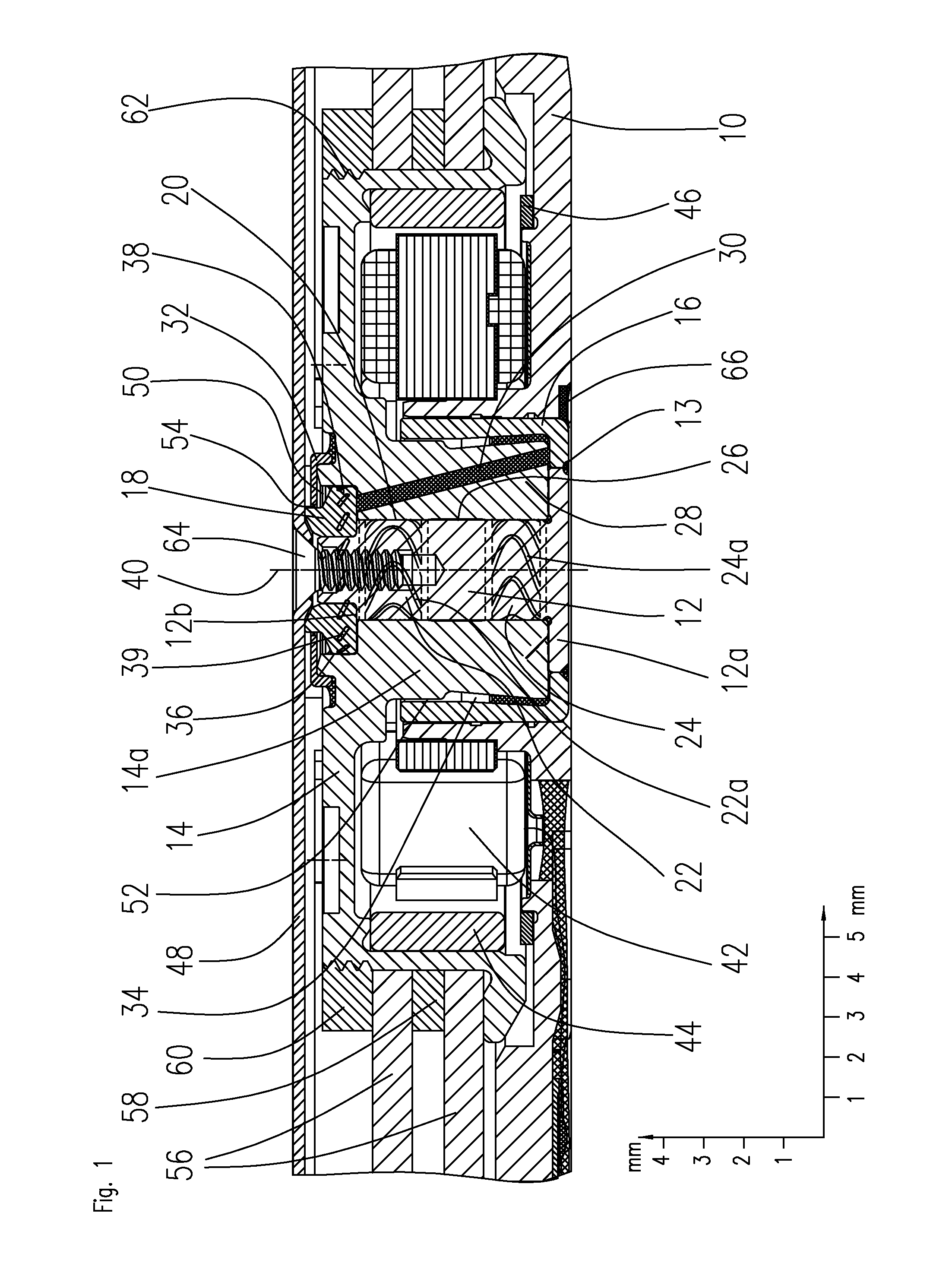

[0029]FIGS. 1 to 3 show three slightly different embodiments of a spindle motor according to the invention having a low overall height and a fluid dynamic bearing system. This kind of spindle motor can be used for driving the storage disks of a hard disk drive.

[0030]The spindle motors according to FIGS. 1 to 3 are largely identical in their basic construction and mainly differ in their overall height and the design of the sealing gaps. FIG. 1 shows a spindle motor having an overall height of approximately 7 mm, whereas FIGS. 2 and 3 show a spindle motor having an overall height of approximately 5 mm.

[0031]The basic construction of the spindle motor according to the invention is described on the basis of FIG. 1. The spindle motor comprises a baseplate 10 that has a substantially central cylindrical opening in which a stationary bearing part 16 is accommodated. The stationary bearing part 16 is approximately U-shaped in cross-section and has a central opening. The stationary bearing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com