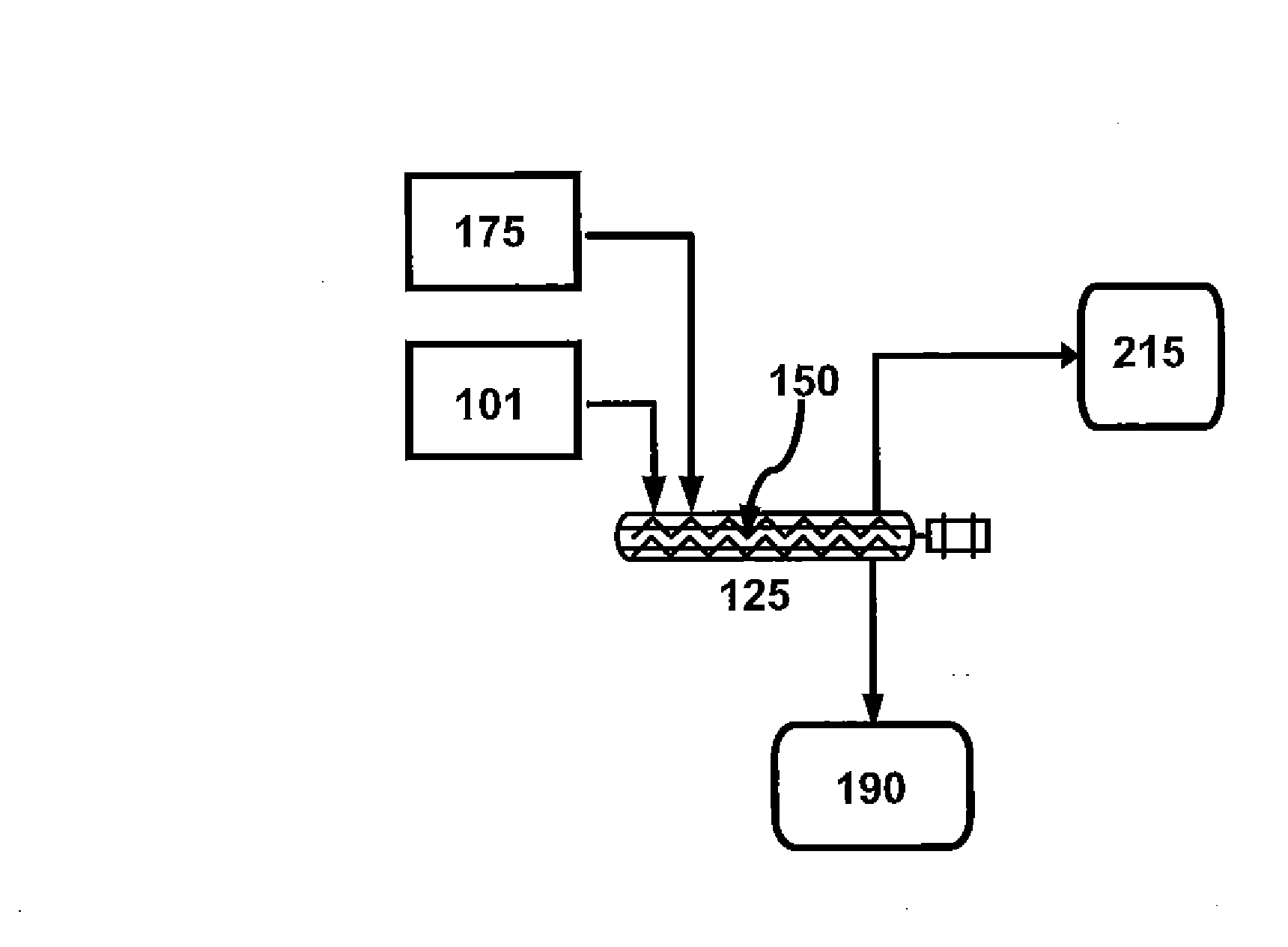

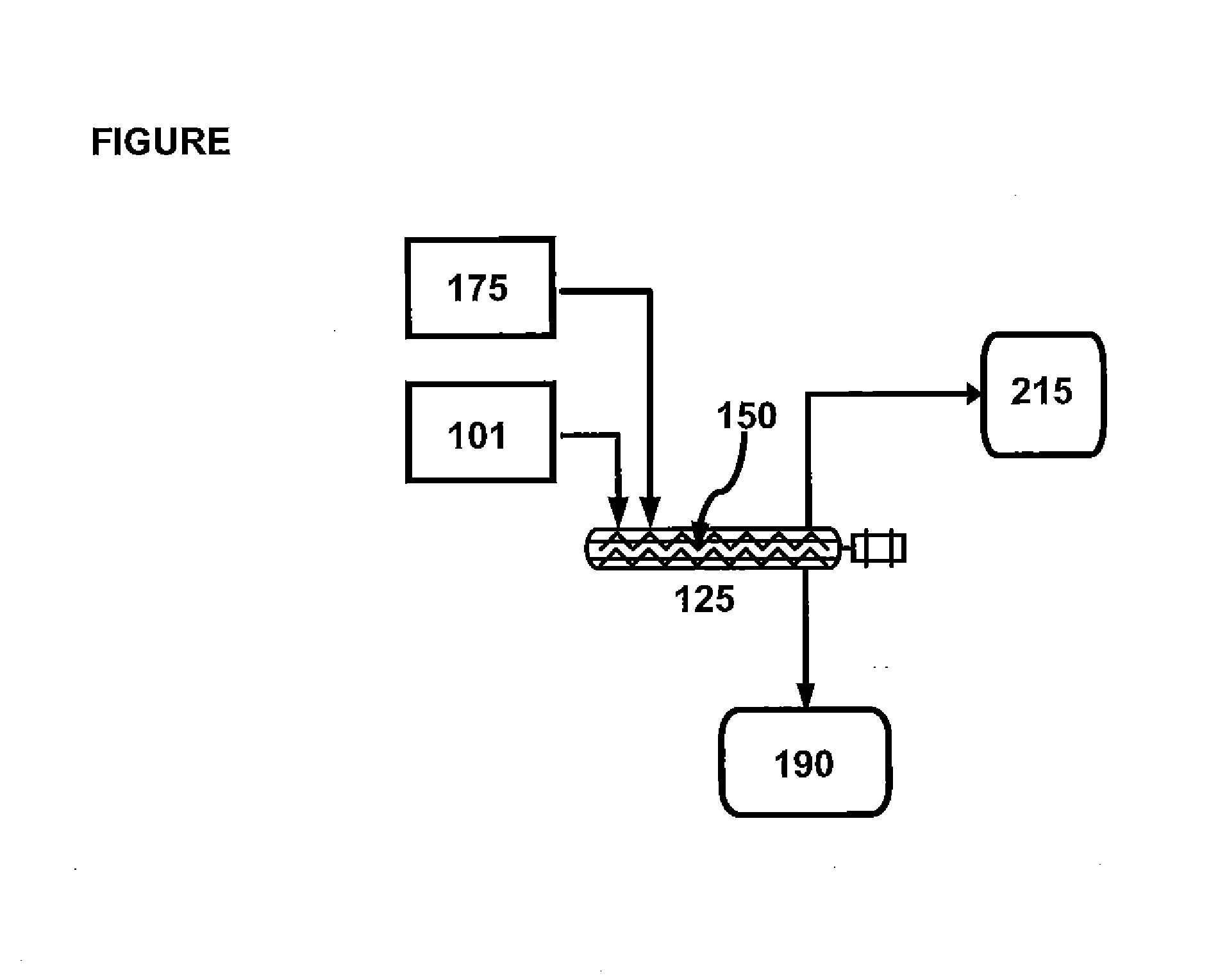

Catalytic biomass pyrolysis in an auger reactor

a biomass pyrolysis and auger reactor technology, applied in the direction of mechanical conveying coke ovens, biofuels, products, etc., can solve the problems of acidic and thermally unstable bio-oil, and achieve the effect of reducing the temperature required for pyrolysis and increasing the rate of pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0035]Either micro-algal or lignin biomass was dried at 70° C. for 12 hours, and then pyrolyzed with and without zeolite catalyst in inert (He) atmosphere. Pyrolysis was conducted at 475° C. pyrolysis temperature, heating rate ˜10,000° C. / s and a 5:1 catalyst ratio (when used). Vapors were analyzed by gas chromatography / mass spectrometry (GC / MS). Char was measured by gravimetric difference. All yields are on a mass basis.

[0036]The data (see Tables 1 and 2) show a greater than 60% yield of condensable vapors from both micro-algal (Table 1) and lignin (Table 2) biomass in un-catalyzed pyrolysis and 50% or greater yield during catalyzed pyrolysis. Adding a zeolite catalyst improved yield of hydrocarbons in the vapor phase, while also increasing char yield.

TABLE IYield of pyrolysis products from dried, whole microalgae.Yield %,Yield %,Productno catalystzeolite catalystNoncondensable gas*617Char*1928Condensable vapors*7455Hydrocarbons in vapor**944*Yield based on total biomass**Yield bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com