Tubular Heater With External Thermocouple

a heater and thermocouple technology, applied in the direction of lamination control, transportation and packaging, packaging, etc., can solve the problems of inability to accurately control the temperature of the heating element, inconsistent or sloppy welds can be problematic, and the source of error, so as to improve the accuracy of temperature measurement, reduce electromagnetic interference, and reliable and accurate temperature monitoring system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

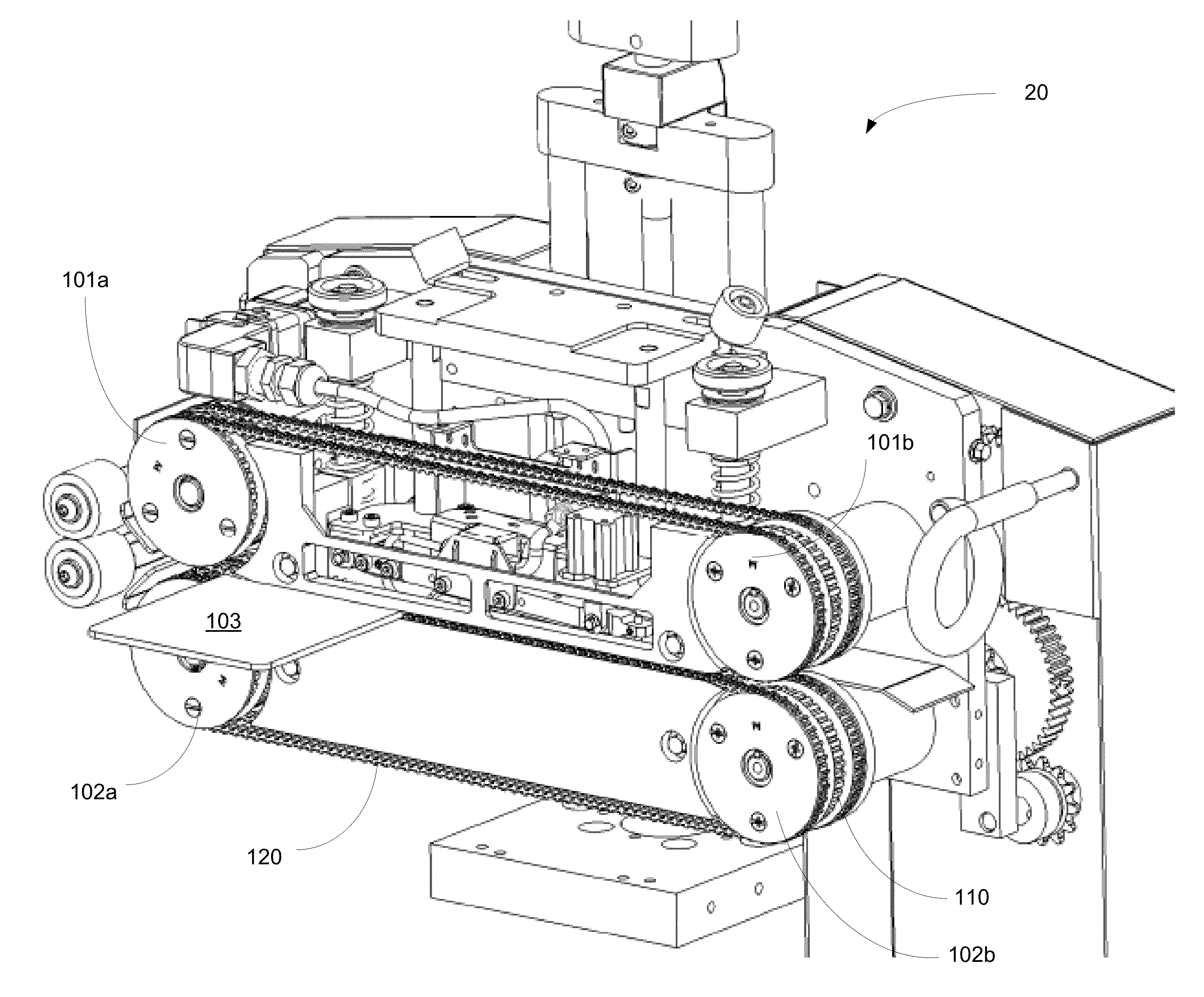

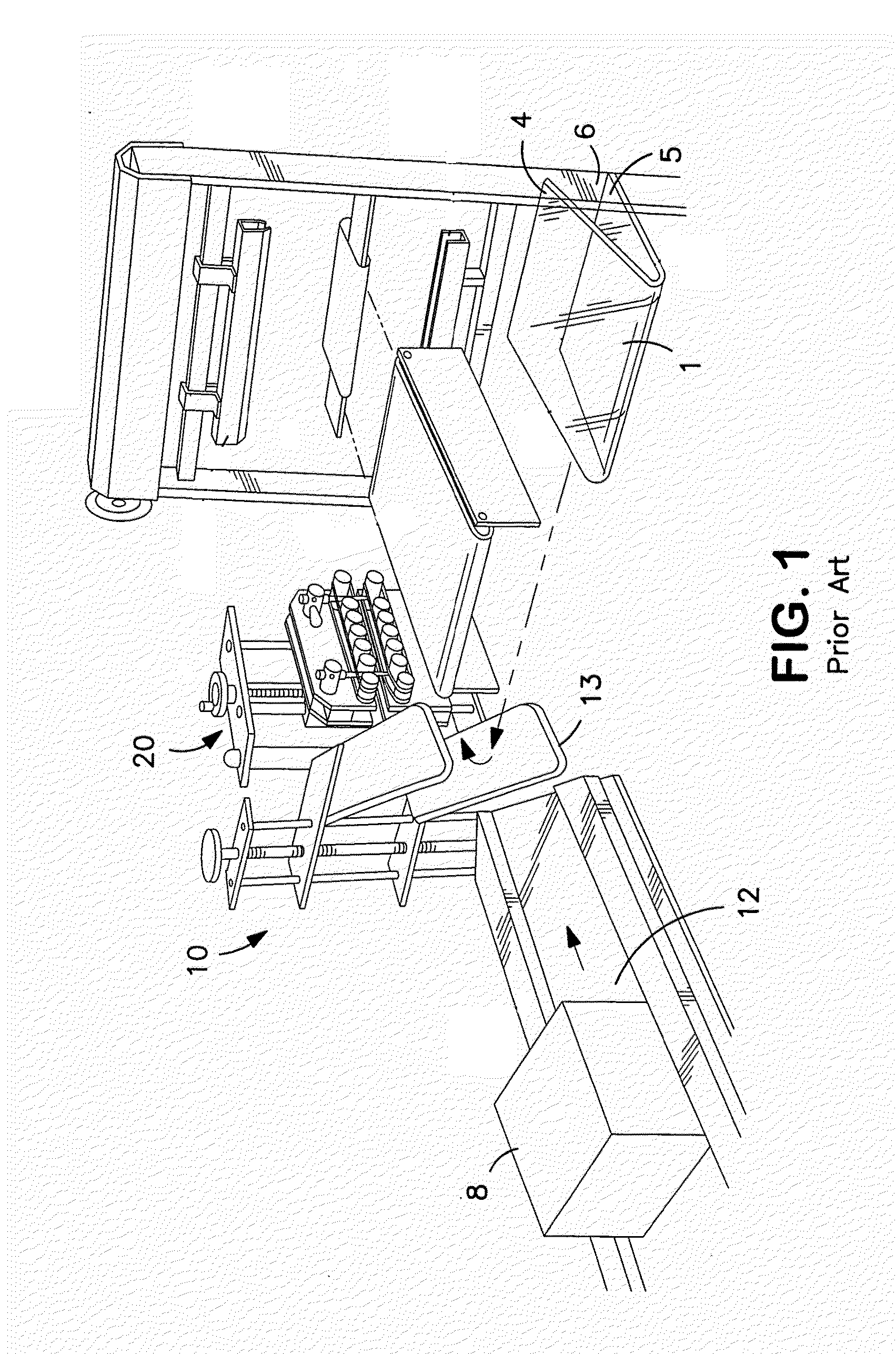

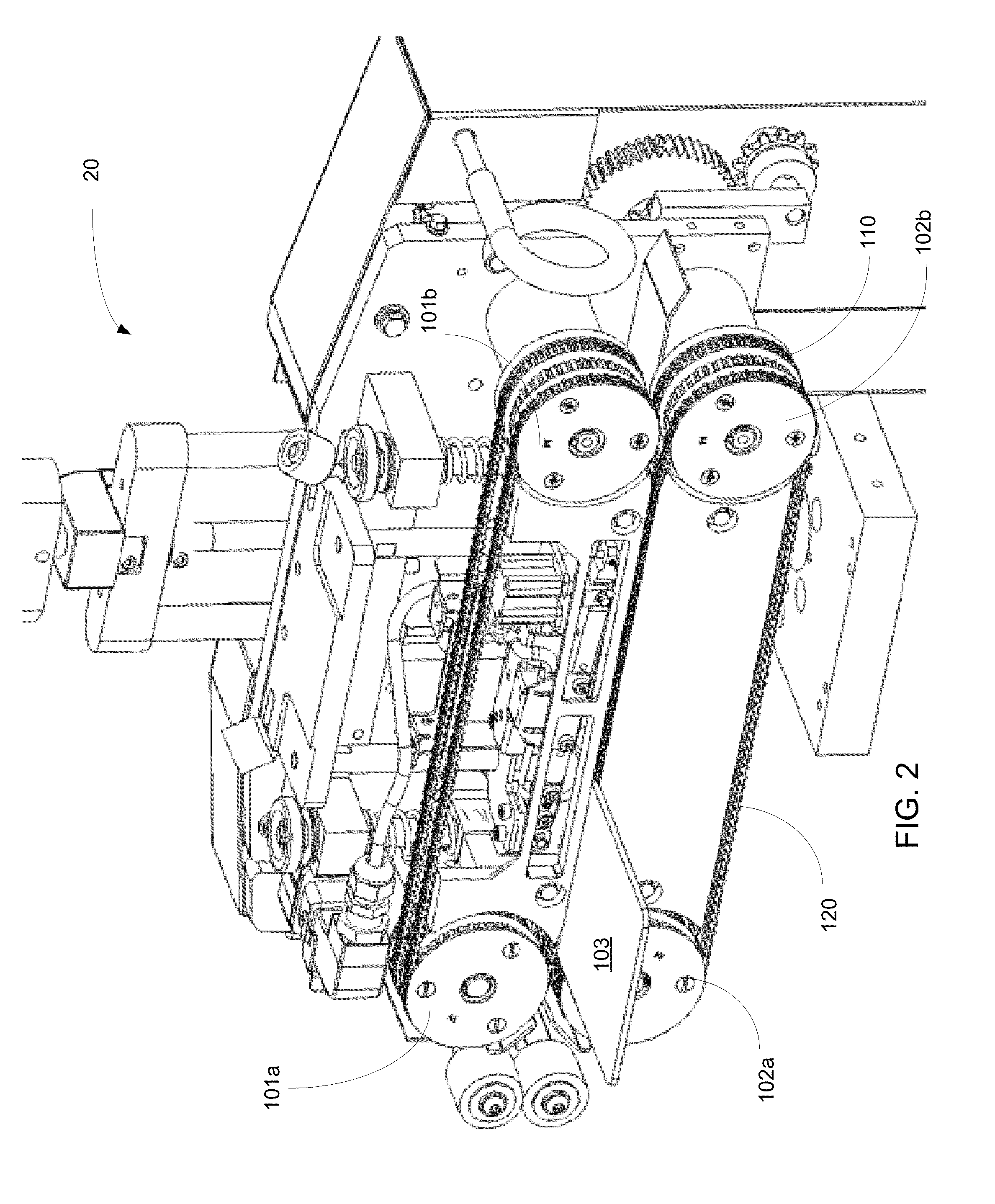

[0019]FIG. 1 illustrates a representative side-sealing machine used to encapsulate or wrap an article in thermoplastic film, as described in U.S. Pat. No. 6,526,728. The machine 10 utilizes a conveyor belt 12 operating at a relatively constant speed to deliver articles 8 that are to be encapsulated. The thermoplastic film 1 is center-folded, such that the side with the fold is closed, while the opposite side 6 is open. On this opposite side, there are two layers of film 4,5, which will later be sealed. This center-folded thermoplastic film 1 is fed from a reel (not shown) that is preferably mounted such that the film is fed perpendicular to the direction of travel of the conveyor belt 12. The film is then inverted and separated by an inverter 13 such that the article is enveloped between the two layers 4,5. At this point, the film 1 on one side of the article is closed, while the opposite side 6 remains open. Also, the film at both the leading and trailing ends of the article are no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com