Melt container

a technology of container and smelt, which is applied in the field of smelt containers, can solve the problems of large economic loss, damage to the iron crust, and problem of melt leaching out, and achieve the effect of preventing the contamination of the smelt of impurities and suppressing the penetration of the smel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

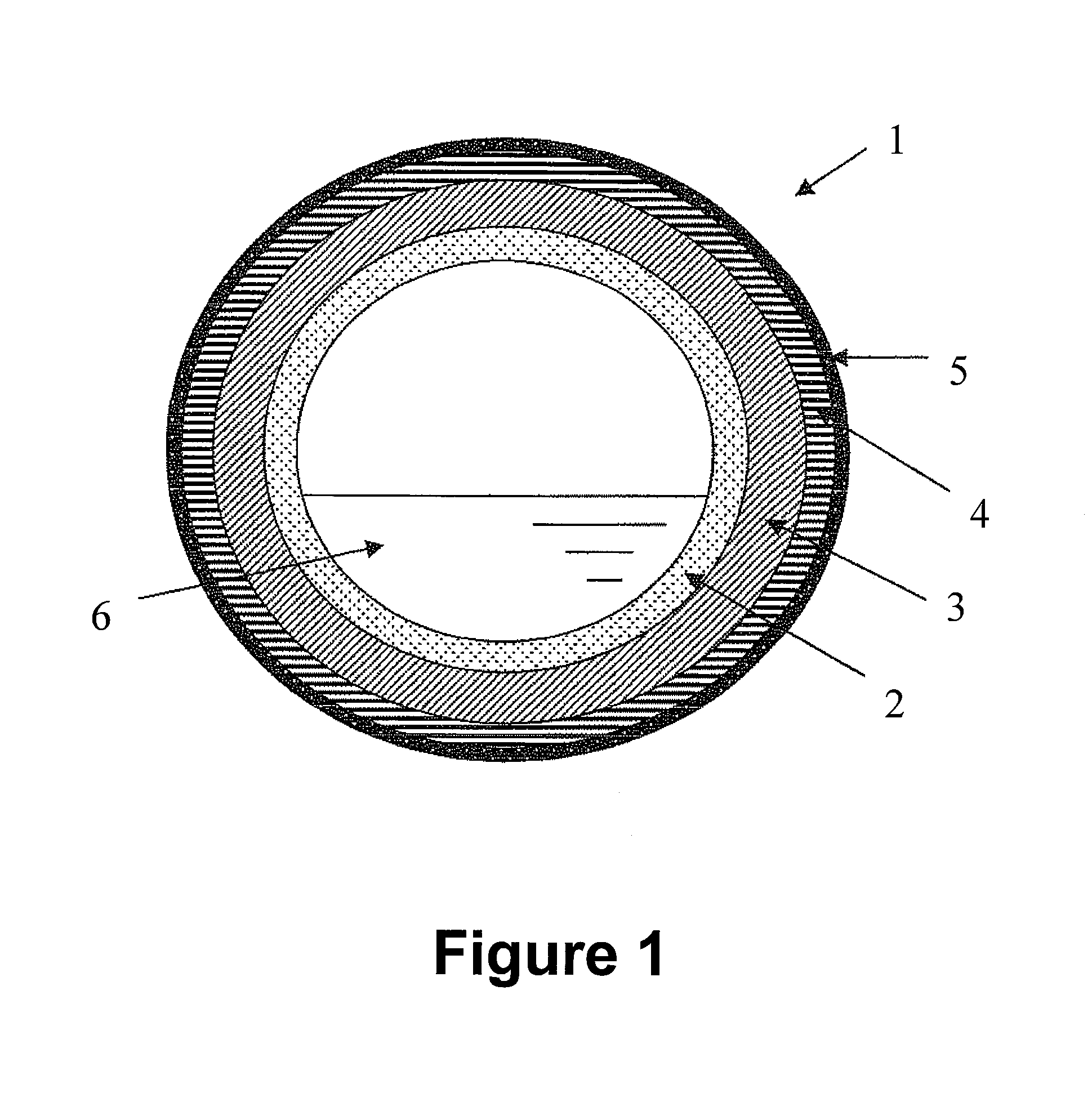

(1) Manufacture of a Melt Container

[0074]As members that constitute a melt container, refractory A (FLEXITE KERSIK-PB, made by NIHON TOKUSHU ROZAI Co., Ltd.) and refractory B (FLEXITE TM-65C3, made by NIHON TOKUSHU ROZAI Co., Ltd.) both having a composition and physical properties shown in Table 1, and a vertical cylindrical iron container (outer diameter: 75 cm, length: 75 cm, thickness: 6 mm) were used.

[0075]A lining of refractory A was made at a thickness of 50 mm inside the vertical cylindrical iron container to form a layer constituted of the refractory A (third layer). A lining of refractory B was further made at a thickness of 150 mm on the layer constituted of the refractory A (third layer) to form a layer constituted of the refractory B (second layer). Furthermore, a lining of refractory A was made at a thickness of 50 mm on the layer constituted of the refractory B (second layer) to form a layer constituted of the refractory A (first layer). Then, each of refractory A and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com