Noise suppressor for firearms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

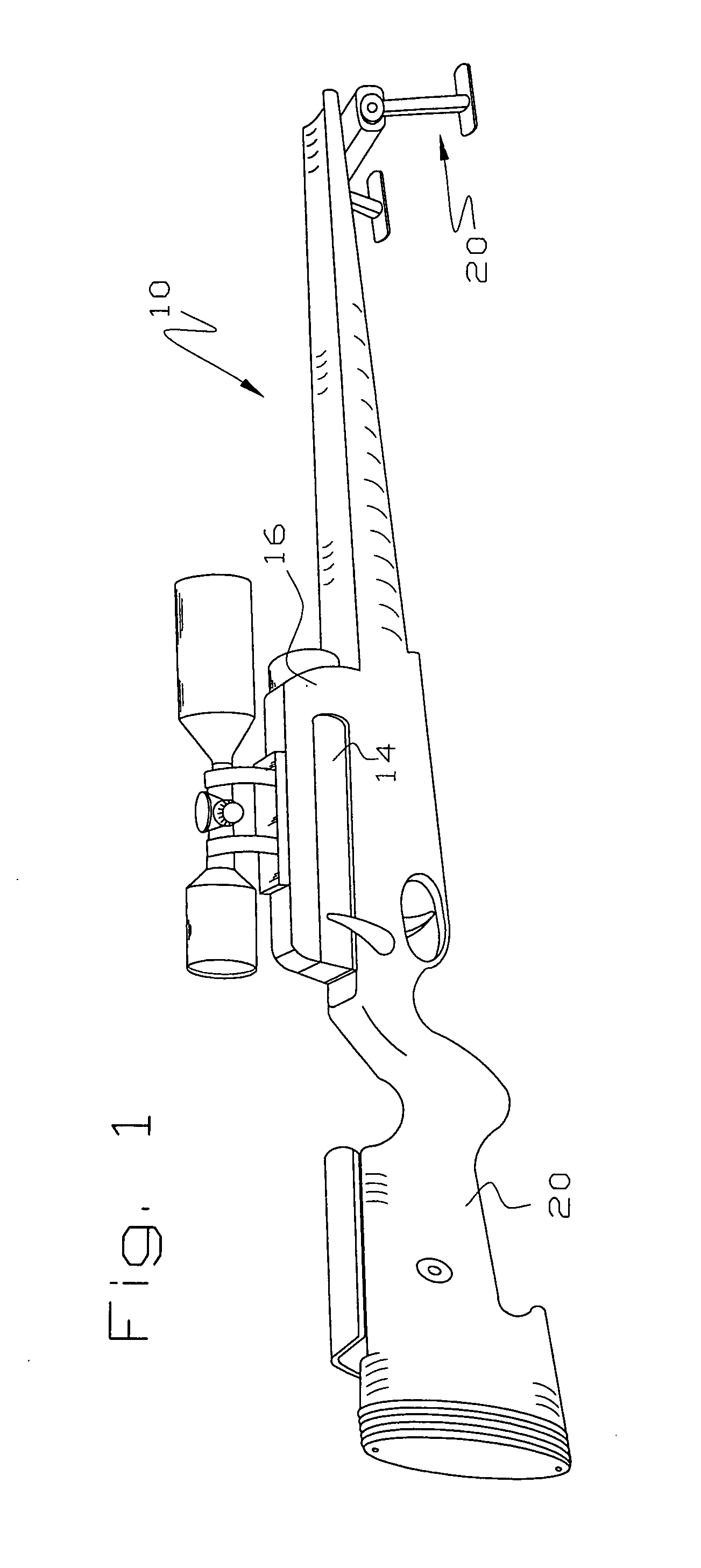

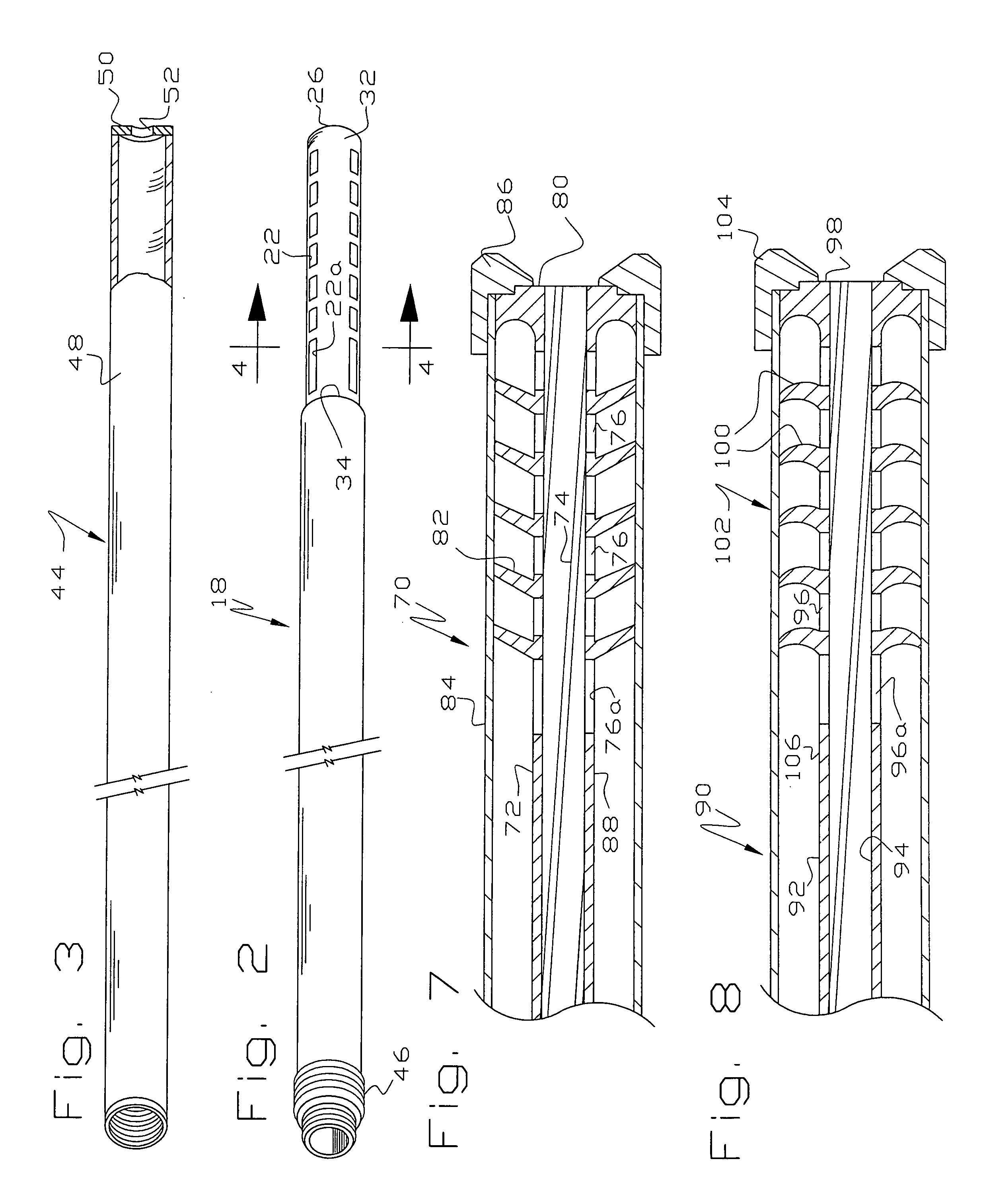

[0025]Referring to FIGS. 1-2, a rifle 10 may be a bolt action type having a stock 12, a bolt 14, a receiver 16, a barrel 18 which threads into the receiver 16 and a bipod support 20. Those skilled in the art will recognize the rifle 10 as being a conventional rifle illustrated as a generic sniper rifle.

[0026]As shown best in FIGS. 2 and 4, the barrel 18 is machined to provide a series of ports 22 that open into the bore 24. Provided there are no burrs where the ports 22 intersect the bore 24, the ports 22 do not scratch or mar the projectile passing through the barrel 18. Thus, if a sabot round were to be fired through the barrel 18, it stays intact as it passes the ports 22, i.e. until the round clears the muzzle or muzzle end 26 of the barrel 18.

[0027]Rifling along the barrel, i.e. alternating lands 28 and grooves 30, spin the projectile and thereby impart considerable stability to it. Grooves 30 may be formed using any suitable technique, e.g. cut rifling, button rifling, hammer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com