Synthetic coal and methods of producing synthetic coal from fermentation residue

a technology of fermentation residues and synthetic coal, which is applied in the direction of biofuels, fuels, waste based fuels, etc., can solve the problems of difficult chemical or enzymatic attack and breakdown of plant structural materials, and achieve the effect of large energy advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

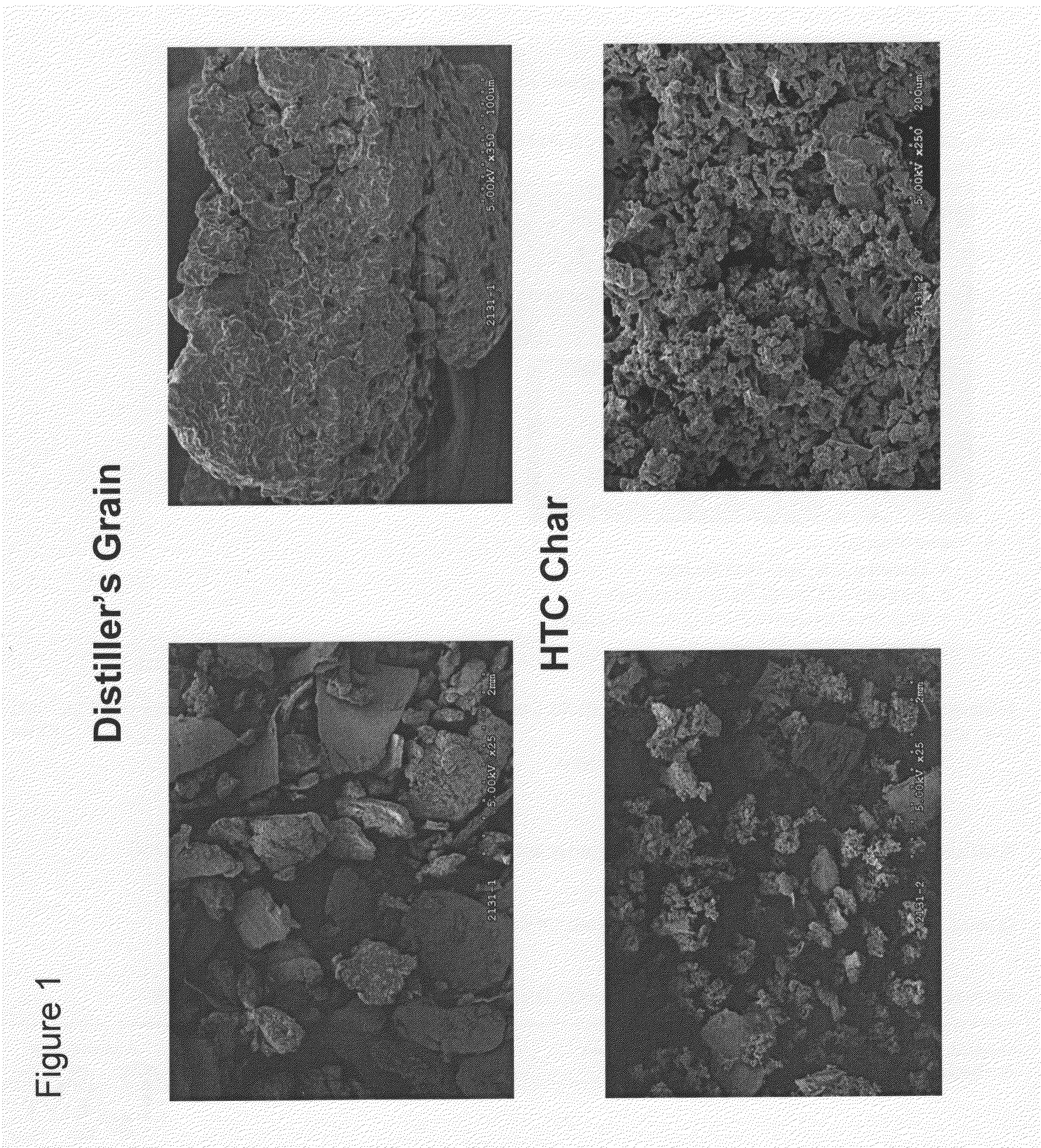

Image

Examples

example 1

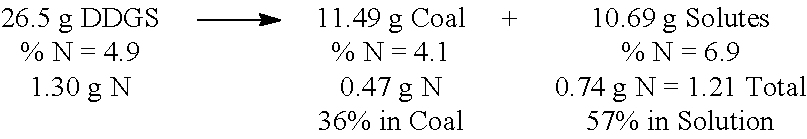

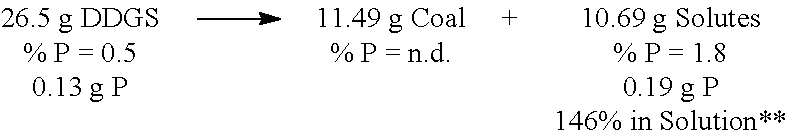

[0047]An experiment was conducted to illustrate the efficient transformation of a fermentation residue from dry distillers' grains with solubles (DDGS), into a high quality coal product comparable to natural bituminous coal. The transformation occurs employing DDGS at about 20% solids content at a temperature of about 200° C. for a period of about 2 hours in the presence of oxalic acid (2% by weight).

[0048]A mixture was prepared by combining DDGS (obtained from Chippewa Valley Ethanol Company (Benton, Minn.) having the following elemental analysis: % C=48.1, % H=7.1, and % N=4.9) (46.5 g), distilled water (186 g) and oxalic acid (0.93 g) in a 500 mL round-bottomed flask and shaken vigorously to create a homogeneous suspension. The suspension was then transferred (98% of the mass) into a 450 mL Parr reactor and stirred at 88 rpm. The reactor was heated to a temperature of 200° C. using the rapid induction heating system, with the initial reaction pressure at about 1.72 MPa.

[0049]Afte...

example 3

[0056]This Example teaches that employment of reaction conditions comparable to reported conditions for lignocellulosic materials are not necessary and less efficient than those required for fermentation residues. The conditions were the same as Example 1 except that a 14 h reaction time was employed. The mass yield of char product obtained from DDGS was 39%. Elemental analysis gave: % C=69.2; % H=7.8; and % N=4.4. The increased reaction time gave a slightly greater level of carbonization (2.2%), but not sufficiently greater to warrant the substantially increased reaction time.

examples 4-6

[0057]These Examples examine multiple DDGS samples of varying composition. The results obtained indicate that DDGS, in general, can be converted efficiently into a high quality coal product, with accompanying aqueous solution byproducts. Samples were obtained from the University of Minnesota Swine Center (Professor Gerald Shurson) and the DDGS web site collection. Three samples were received having the following compositions given in weight percent:

ID#% Fat% Protein% Carbohydrate% AshS0228.7929.8857.593.74S03711.3431.3452.325.00S02612.2932.5639.1815.96

[0058]Each of the DDS samples was subjected to hydrothermal carbonization at 200° C., 15% solids, 2 h reaction time, and with 2% oxalic acid present. Yields and elemental analyses of freeze-dried coals were as follows:

Example% Yield% C% H% N4(S022)42.466.77.73.85(S037)37.167.48.14.06(S026)37.266.67.84.1

These examples show that despite compositional differences in DDGS samples similar synthetic coals are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com