Method for generating hydrogen by using a fuel cell power generation system

a technology of fuel cell power generation and fuel cell, which is applied in the direction of sustainable manufacturing/processing, instruments, final product manufacturing, etc., can solve the problems of increasing the size and manufacturing cost of the apparatus for generating hydrogen, neither the combustion process nor the drive device, and the danger of pemfc, so as to reduce the manufacturing cost and reduce the size of the whole apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]An embodiment of an apparatus for generating hydrogen and a fuel cell power generation system according to the present invention will be described in detail with reference to the accompanying drawings. In description with reference to accompanying drawings, the same reference numerals will be assigned to the same or corresponding elements, and repetitive description thereof will be omitted.

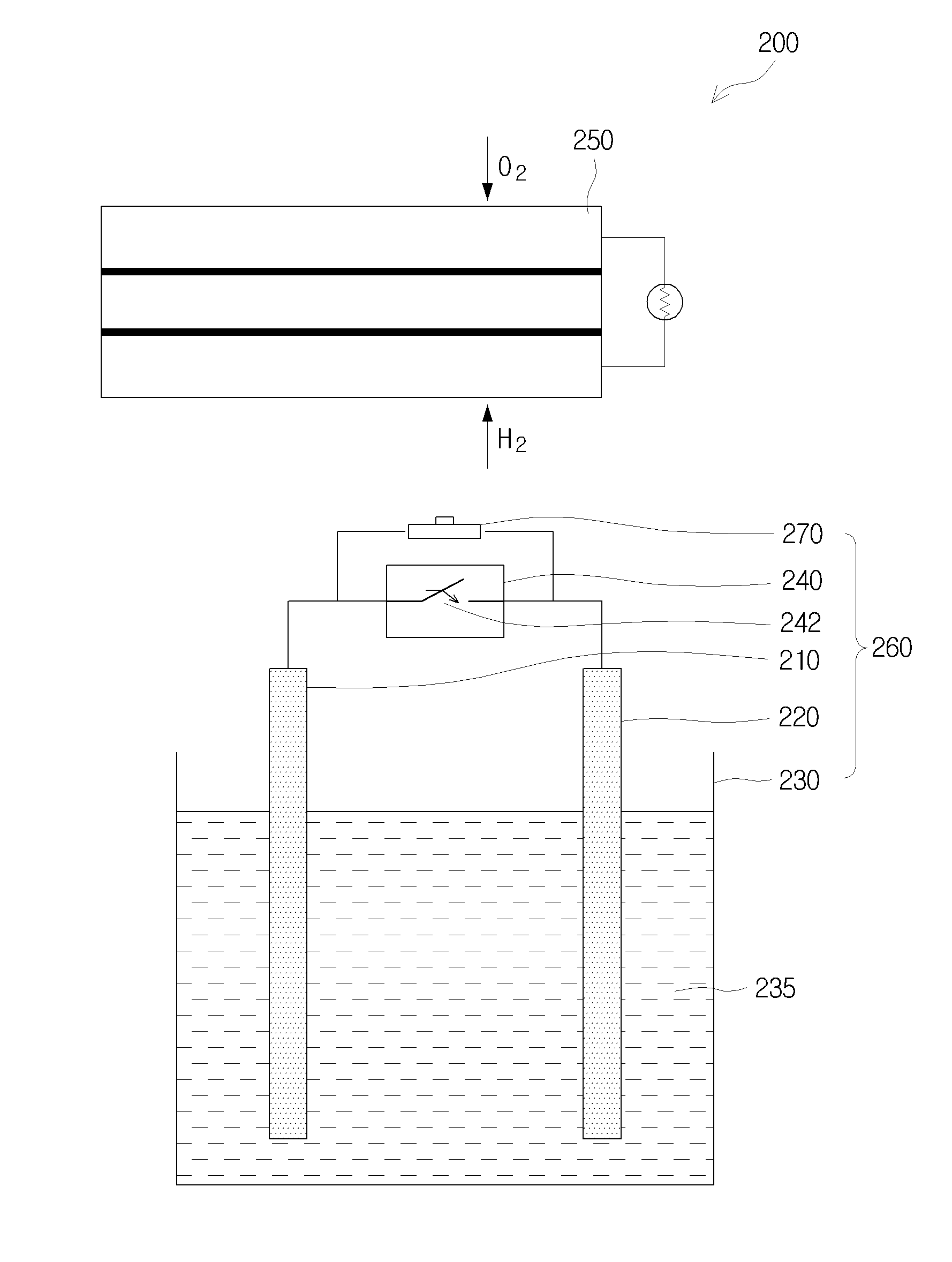

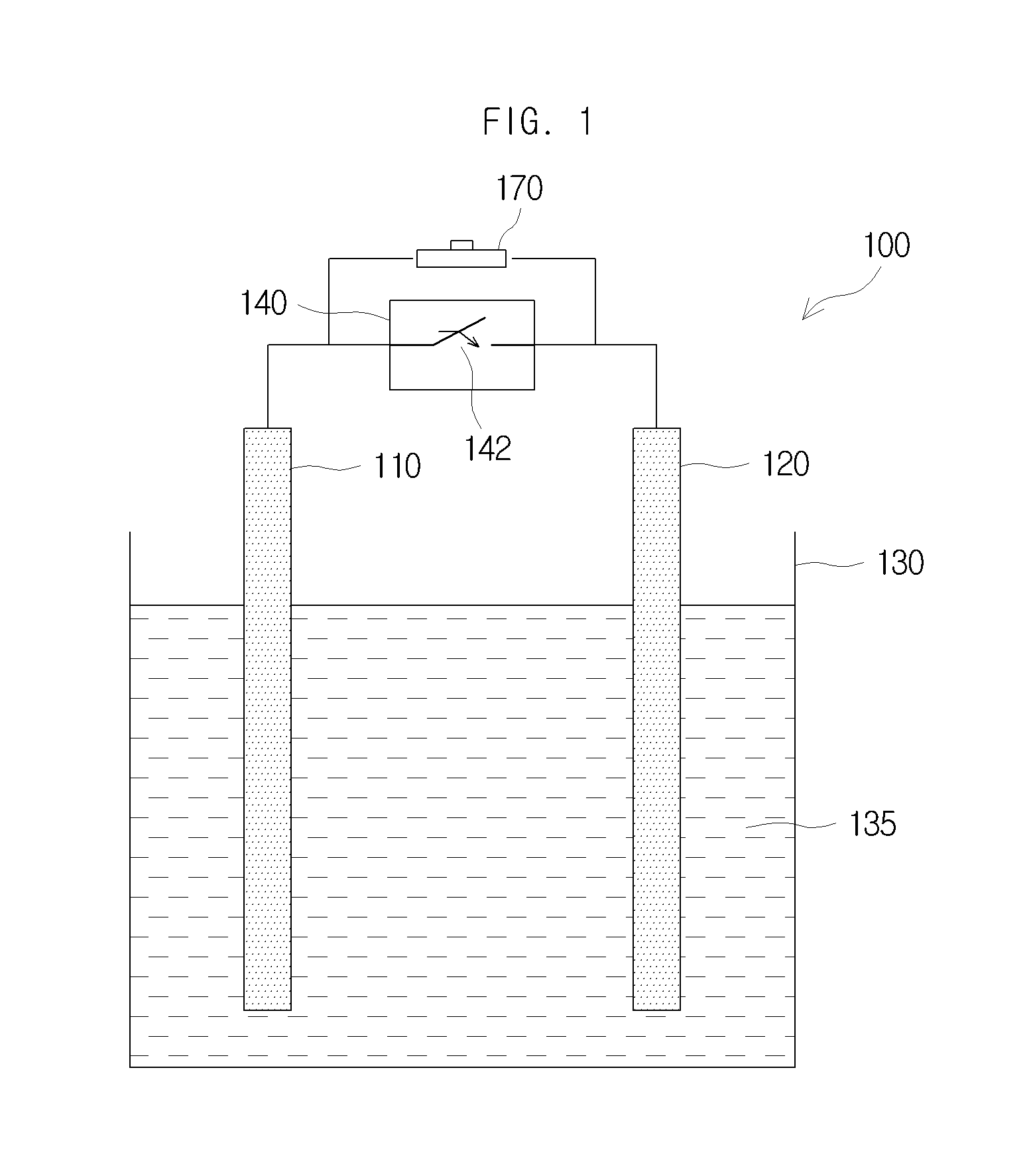

[0017]FIG. 1 is a schematic view showing an embodiment of an apparatus for generating hydrogen according to an aspect of the present invention. Illustrated in FIG. 1 are an apparatus 100 for generating hydrogen, an anode 110, a cathode 120, an electrolytic bath 130, an electrolyte solution 135, a controller 140, an electronic switch 142 and a mechanical switch 170.

[0018]According to the embodiment of the present invention, an auxiliary power source for starting the controller 140 which controls flow of electricity between the anode 110 and the cathode 120 can be removed by electrically conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical energy | aaaaa | aaaaa |

| chemical energy | aaaaa | aaaaa |

| power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com