Pavement crack cleaner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

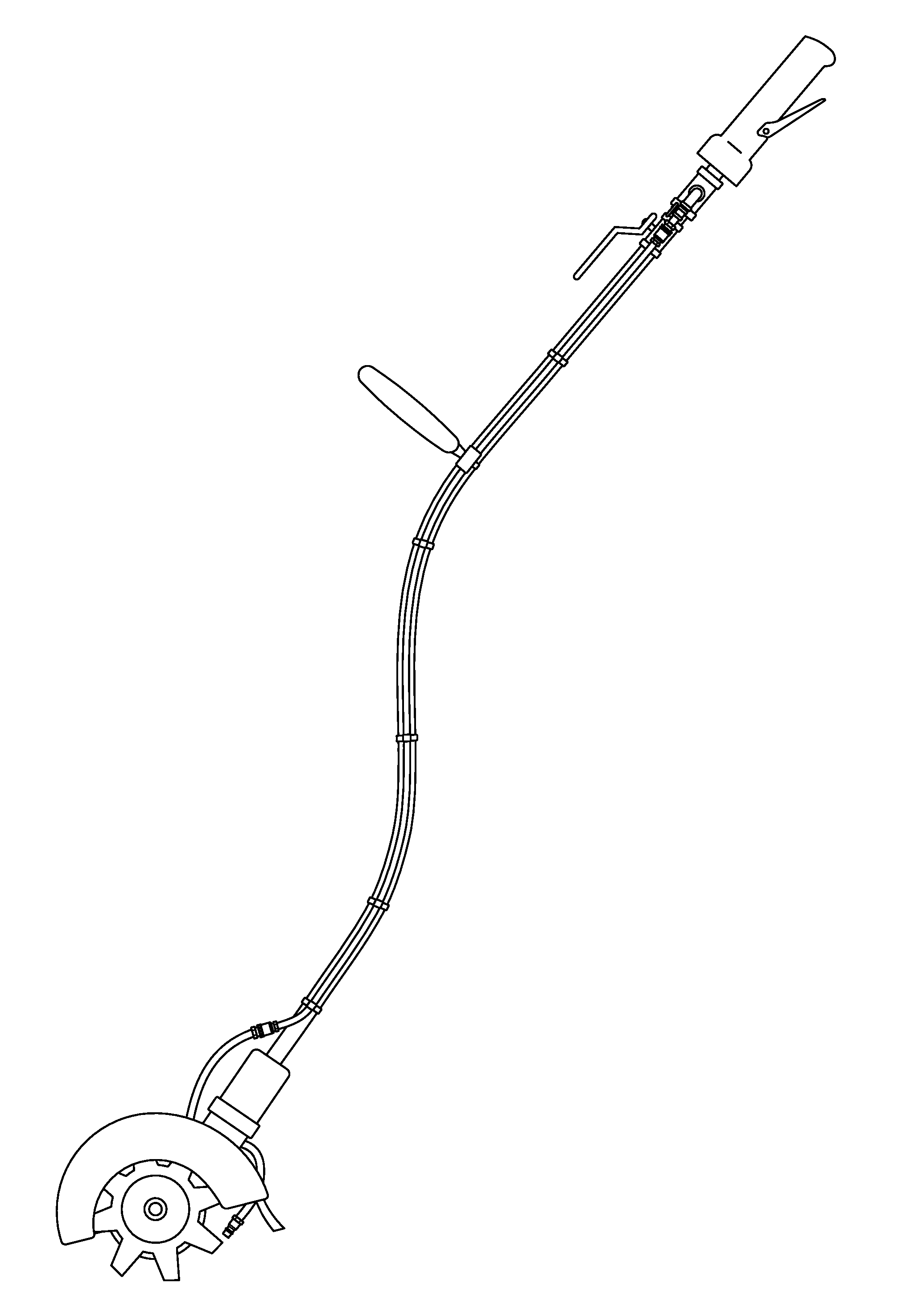

[0017]FIG. 1 is a schematic view showing one of the embodiments of the invention. The lever near the handle at the top of the device allows the user to control the air flow rate to the air blaster. The control switch just below the handle acts to split the air flow between the air blaster and the pneumatically powered motor. The motor is located within the housing just above the guard cover. The guard cover is the semi-circle in the drawing above the pavement router which acts to prevent debris from flying up or to the left of the device as it operates. The primary air blaster nozzle is positioned behind the pavement router.

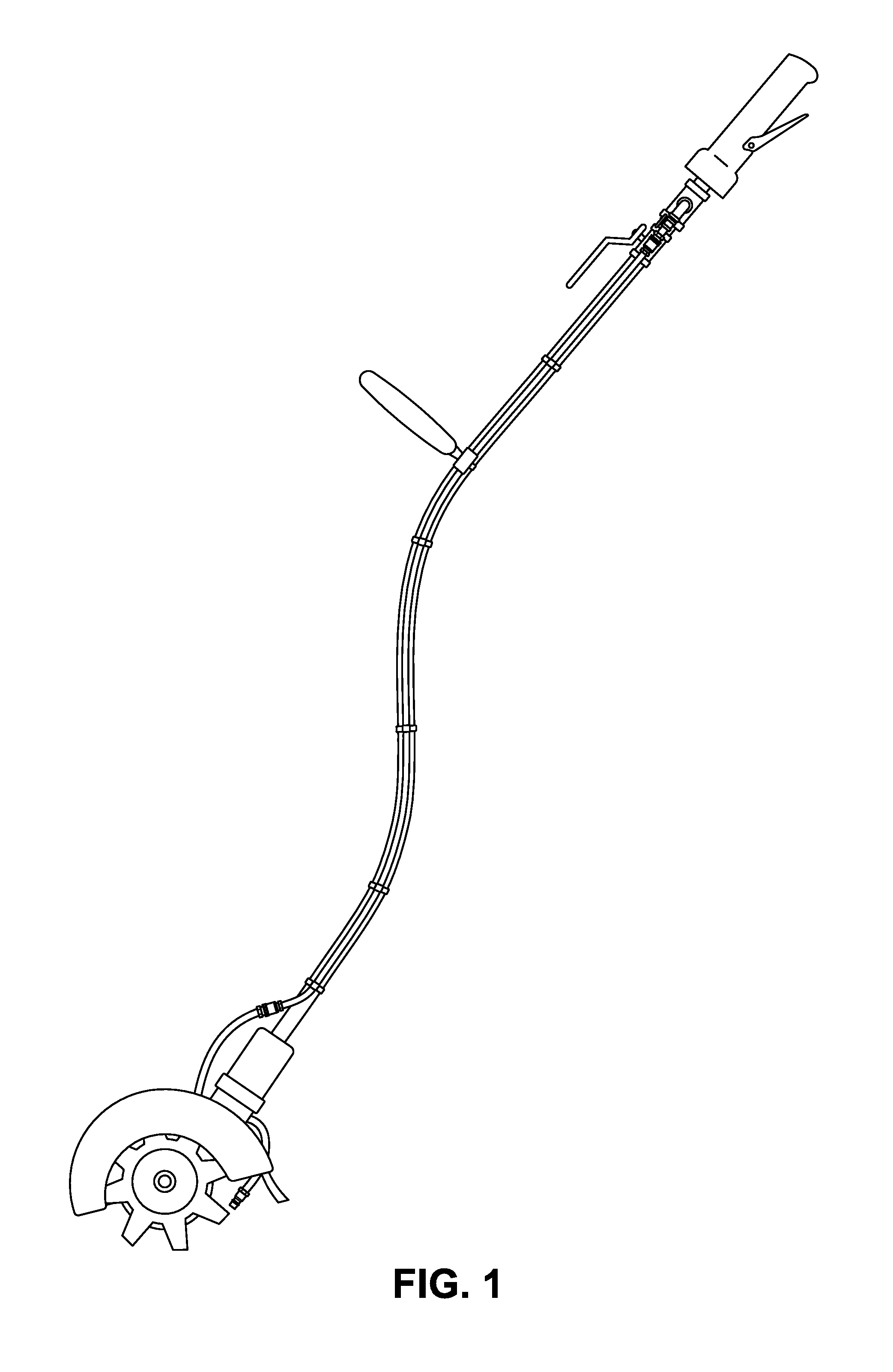

[0018]FIG. 2 is a close-up view of an embodiment showing the wire brush assembly instead of the pavement router. All other aspects of this embodiment are identical to the embodiment in FIG. 1.

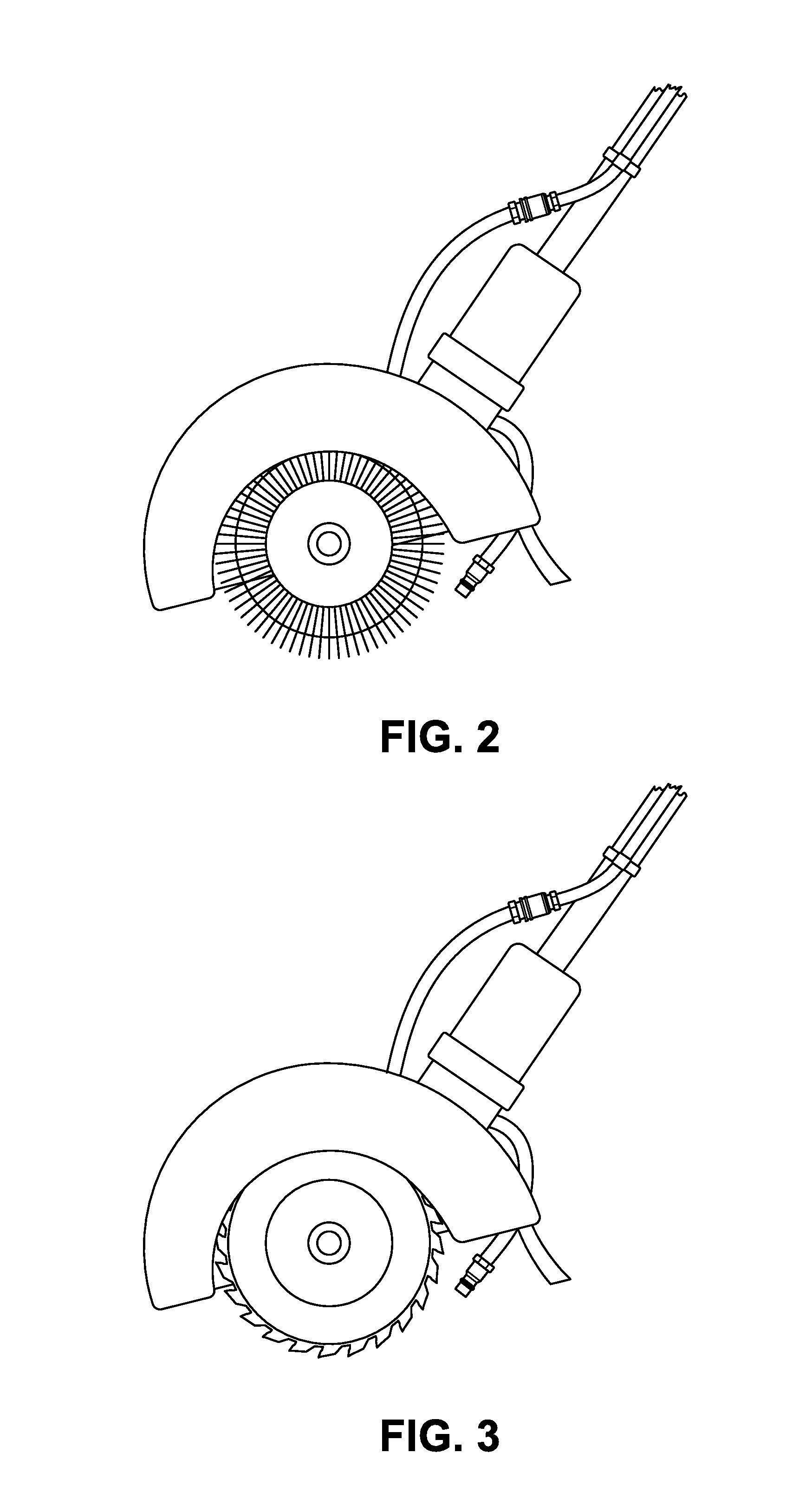

[0019]FIG. 3 is a close-up view of an embodiment showing a masonry bit instead of the pavement router. All other aspects of this embodiment are identical to the embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com