Method and assembly for processing round seed cotton modules

a technology of round seed cotton and processing method, applied in the field of agricultural module processing, can solve the problems of large number of moving parts, complicated apparatus, and complicated construction of machines,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]Although the present invention will be described with reference to its application in cotton processing, it will be appreciated by persons skilled in the art that the assembly to be described below according to various embodiments may be adapted for use in other applications.

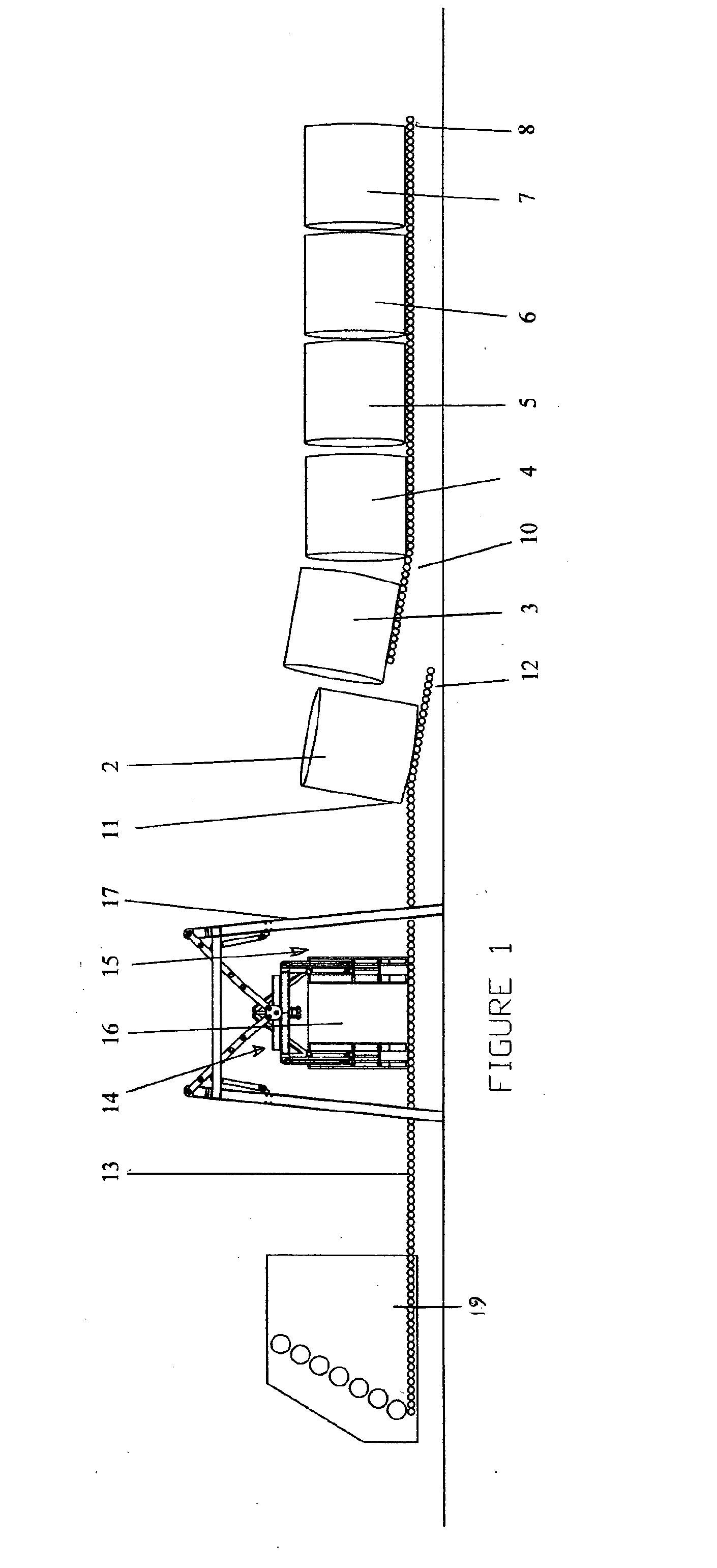

[0054]FIG. 1 shows a side elevation view of a conveyor processing system 1 in which bales 2, 3, 4, 5, 6 and 7 are advanced along a first conveyor 8 towards an apparatus 17. Typically a round seed cotton bale also described as a module is packed using a plastics sleeve which is wrapped tightly about the module usually leaving open ends. Round seed cotton modules can weigh up to three tonne so module handling must be mechanised. The seed cotton is contained under a circumferential compression force induced by tension in the plastics sleeve when the module is wrapped. A round seed cotton module is typically cylindrical such that the plastics sleeve forms a wall for the bale leaving open ends with seed cotton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com