Apparatus and process for treatment of fibers

a technology of fiber bundles and apparatus, applied in the field of process and apparatus for treating fiber bundles, can solve the problems of reducing reducing the efficiency of treatment methods, and reducing so as to reduce the accessibility of reactants, improve water holding capacity, and reduce the length of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

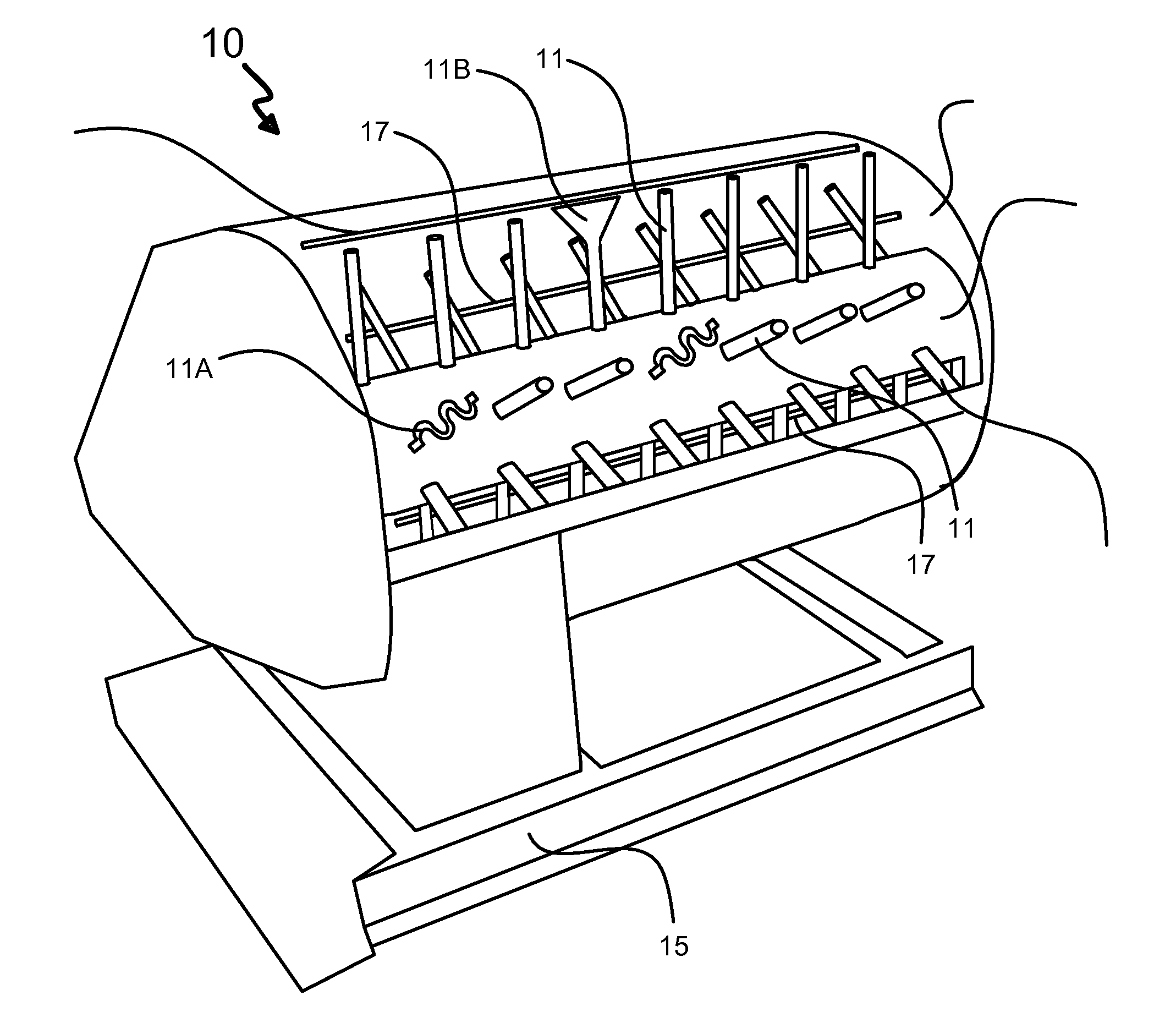

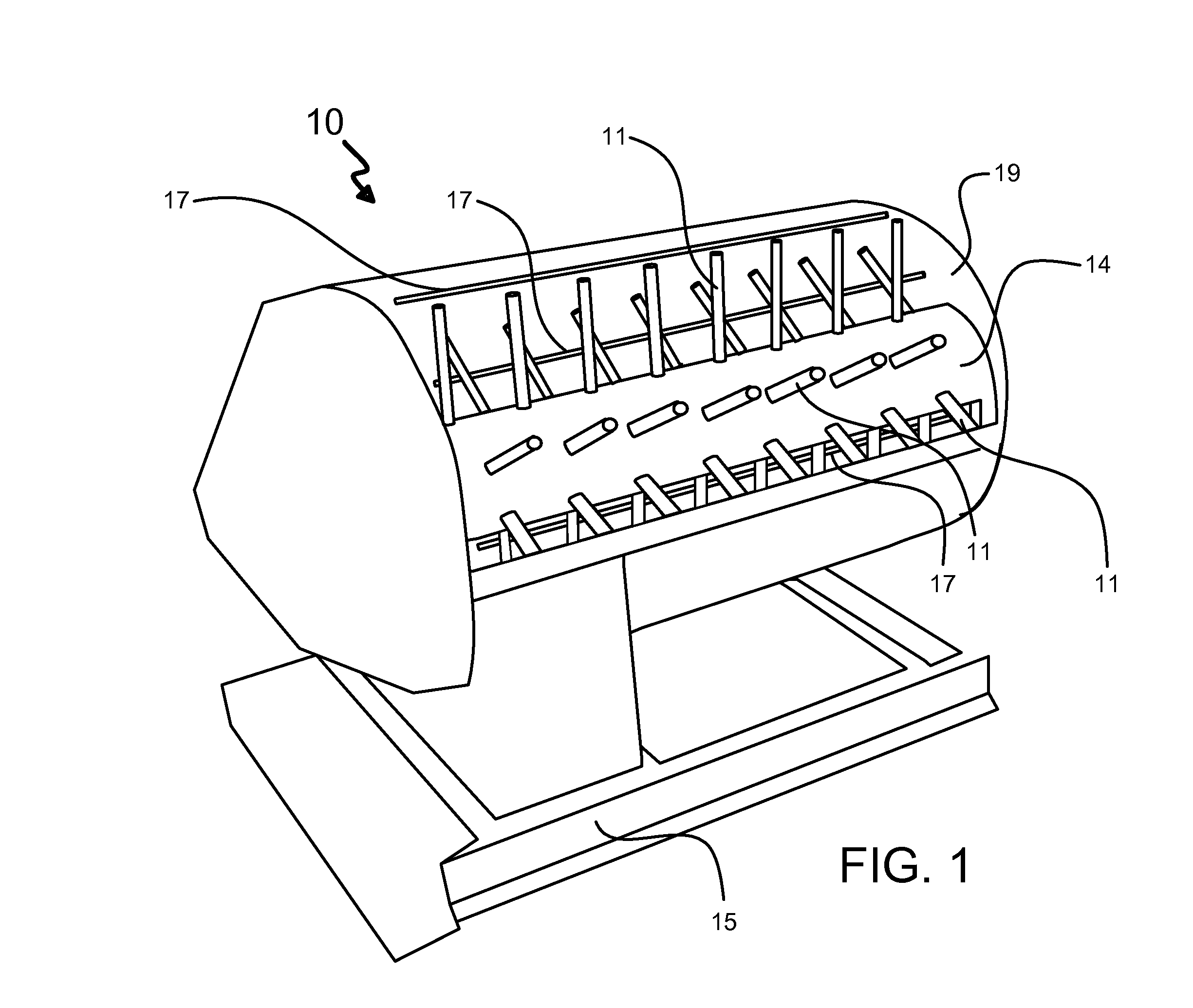

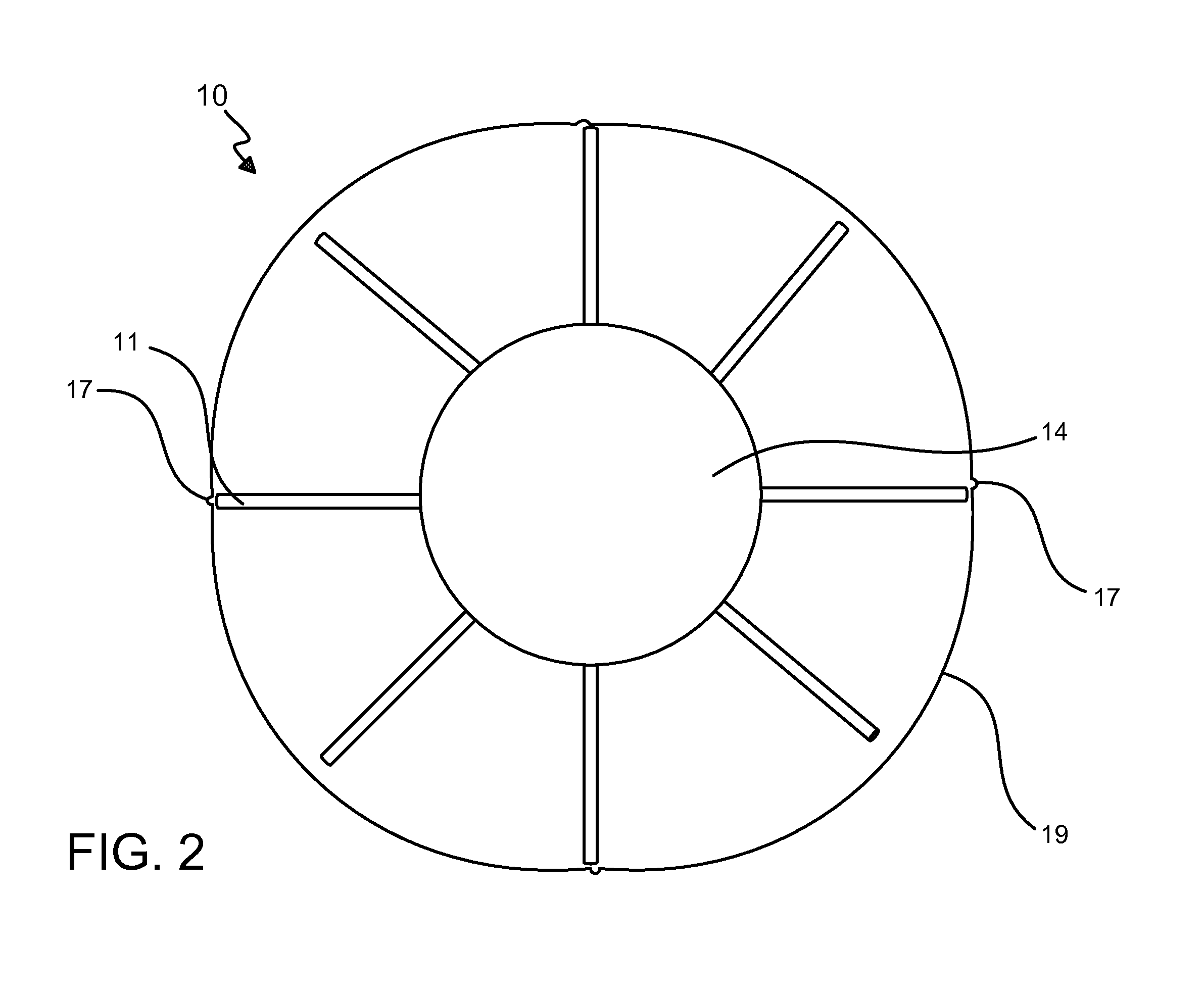

Image

Examples

examples

[0031]The following tables provide ethanol conversion efficiencies and water holding capacity measurements for treated fibers resulting from two fiber treatment processes. The fibers originated from several biomass sources.

[0032]Untreated fibers were produced by macerating the fibers in a pin mixer in the presence of steam at about 150 degrees C. and a pressure of about 2 Kilo Pascal gauge for about 10 minutes but without the introduction of chemicals into the treatment vessel.

[0033]Process 1 comprised of spraying the fibers bundles with a 4% Calcium Oxide by weight of oven dried fibers, macerating the fibers in a pin mixer in the presence of steam at about 150 degrees C., and ammonia originating from heating a solution containing about 5% urea by weight of the dry fibers. The pressure in the treatment vessel was 2 Kilo Pascal gauge. The process was carried out for 5 minutes of dwell time and for 10 minutes of dwell time in the treatment vessel.

[0034]The treated fibers were collecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com