Method of using light-emitting diode (LED) lighting to illuminate the interior of microwave ovens

a technology of light-emitting diodes and microwave ovens, which is applied in the direction of lighting and heating apparatus, domestic cooling apparatus, furnaces, etc., can solve the problems of high filament temperature, bulb burning out, and bulb being vulnerable to microwaves, and achieve good contrast ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

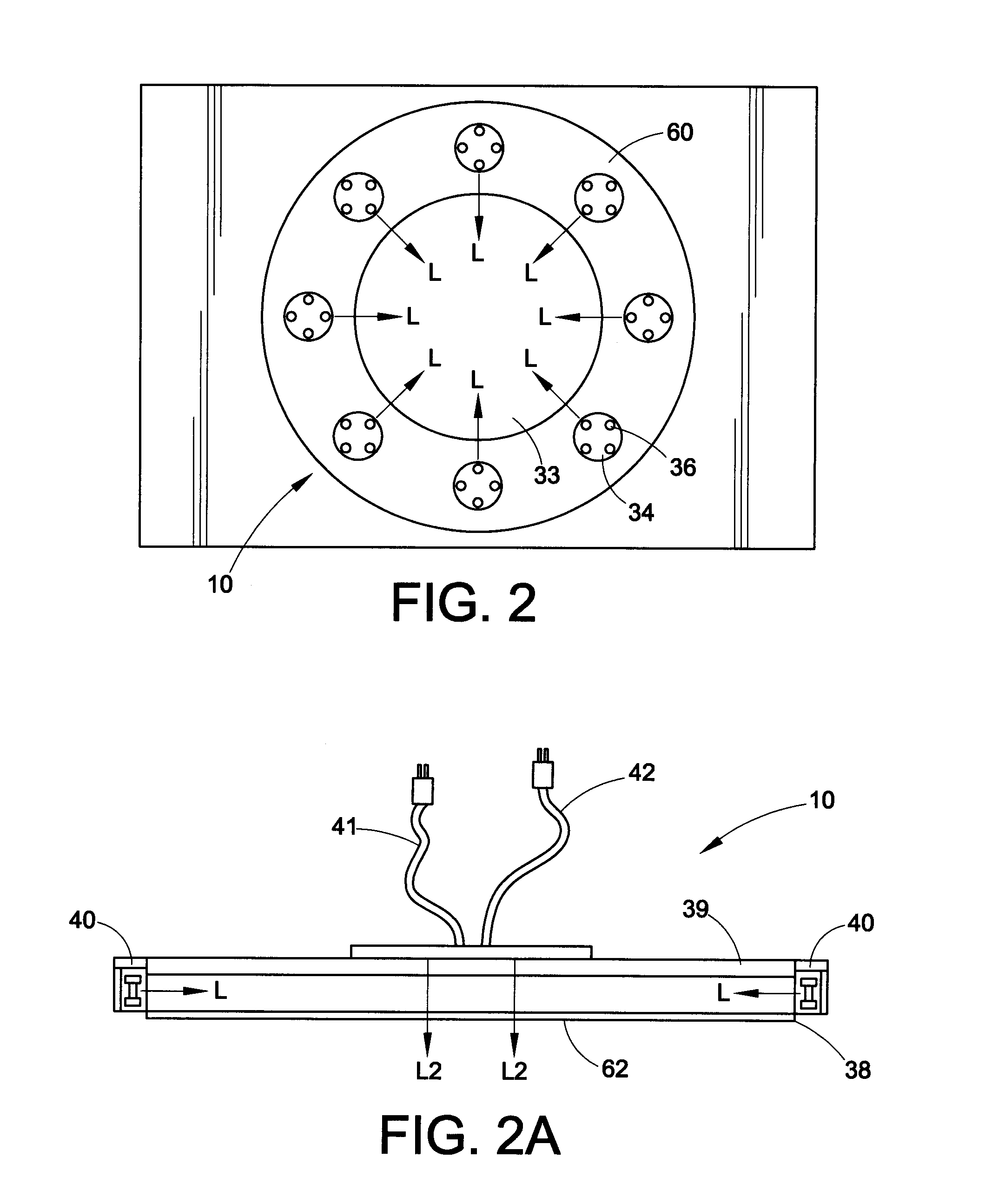

[0022]A conventional microwave oven has a front door, a rear wall, interior side walls and a floor or bottom wall forming an interior chamber or cavity of the oven. In existing microwaves, a standard appliance-type tungsten filament lamp is positioned in a chamber or panel within one or more of the side walls. The lamp is positioned to be out of the path of microwaves within the cavity. In addition, a screen covers the lamp within the chamber or panel.

[0023]In addition to a reduced amount of light being available from the incandescent lamp because of its location in the chamber, the screen reduces the available light by another 50 percent or so, so that a 25 watt bulb effectively delivers only about 4% of its emitted light to the oven cavity in a conventional microwave oven. In addition, the location of the chamber is generally on a side wall of the oven so that the contents of the oven are lit only from the sides, so much of the incident light is not directed toward the oven door, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com