Pipeline assembly comprising an anchoring device

a technology of pipeline and anchoring device, which is applied in the direction of pipe laying and repair, waterborne vessels, mechanical devices, etc., can solve the problems of pipeline fatigue, movement and rotation of the target device, loss in lifetime, etc., and achieve the effect of reducing pipeline movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

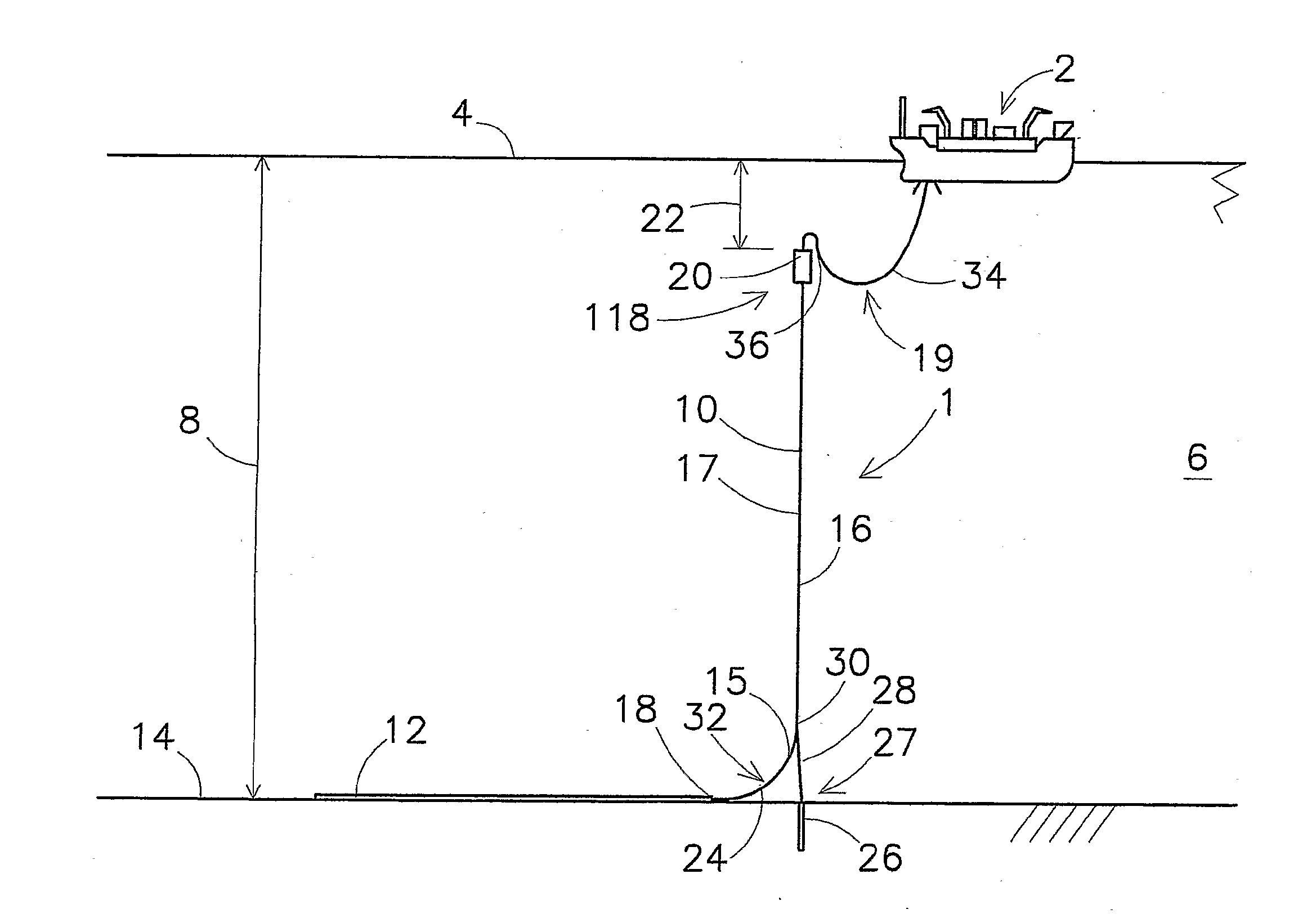

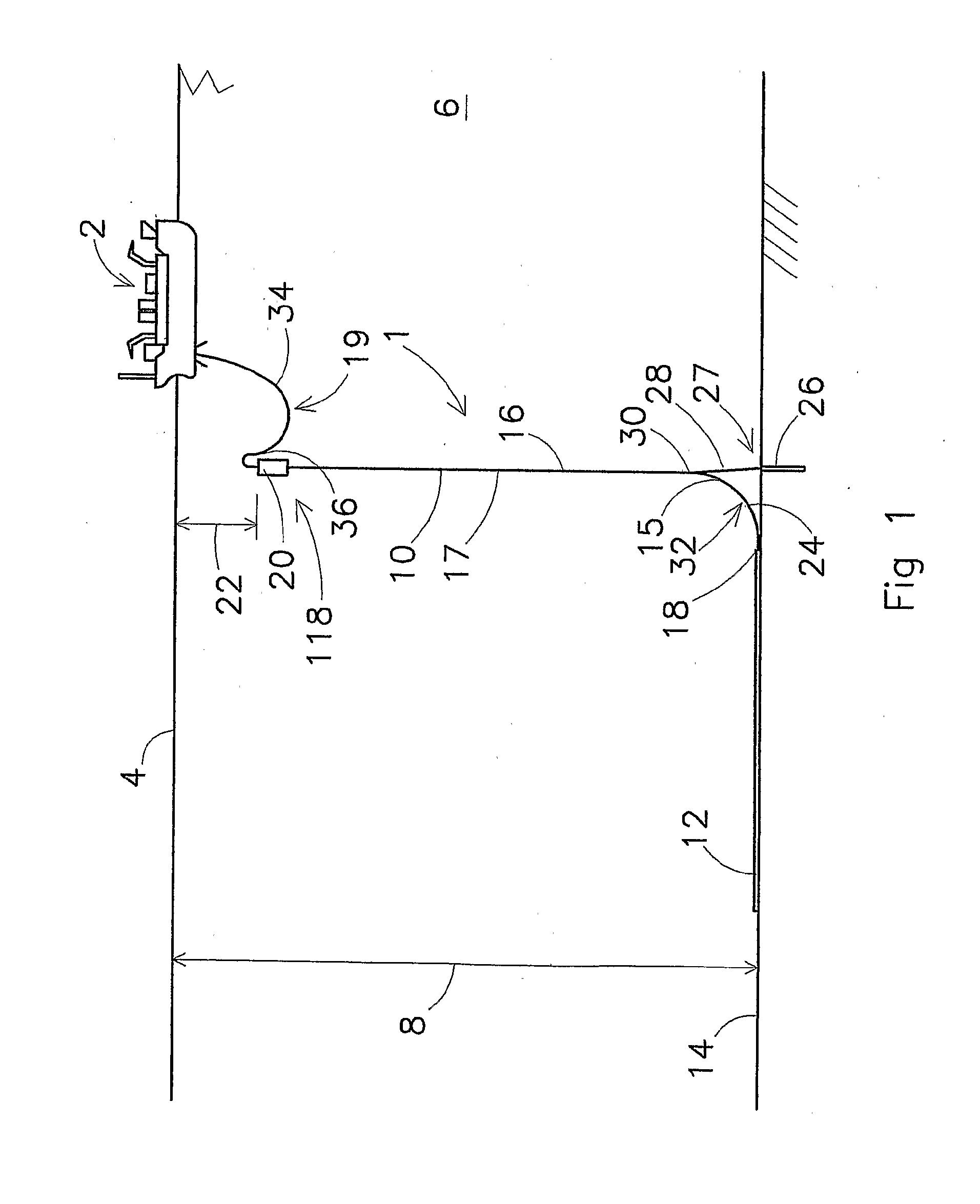

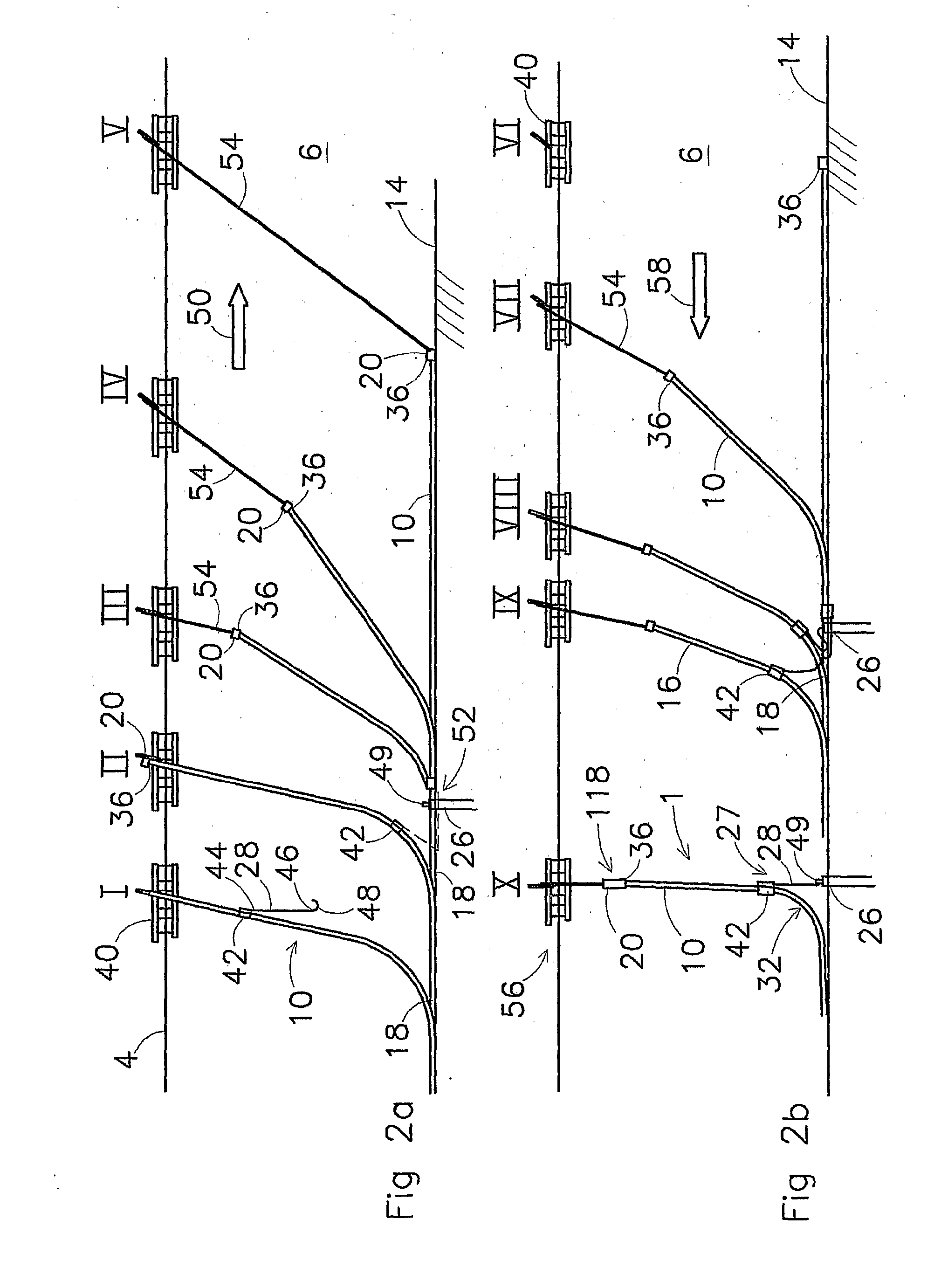

[0139]FIG. 1 shows an embodiment of a pipeline assembly 1 according to the invention. A target device 2 is shown, positioned at a water surface 4. The target device 2 may be an FPSO, or a different kind of vessel. The water 6 may have a substantial depth 8, for instance ranging between one and three kilometres.

[0140]A pipeline 10 comprises a seabed section 12, which rests on a seabed 14, and a riser section 16, which extends from a touchdown point 18 at the seabed 14 to a buoyancy device 20, positioned at a depth 22 under the water surface 4. The buoyancy device 20 exerts an upward force on the pipeline 10. The depth 22 is chosen such, that the buoyancy device 20 is substantially free of forces of waves and wind. At least one flexible pipeline 34 connects a delivery end 36 of the pipeline 10 to the target device 2 for providing a fluid connection between the delivery end 36 and the target device 2. The seabed section 14 may be connected at one end thereof to an oil well (not shown)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com