Novel implant inserter having a laterally-extending dovetail engagement feature

a technology of engagement feature and implant, which is applied in the field of implant inserter with laterally extending dovetail engagement feature, can solve the problem of not being able to ensure that the anterior surface of the implant bottoms out on the inserter tip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

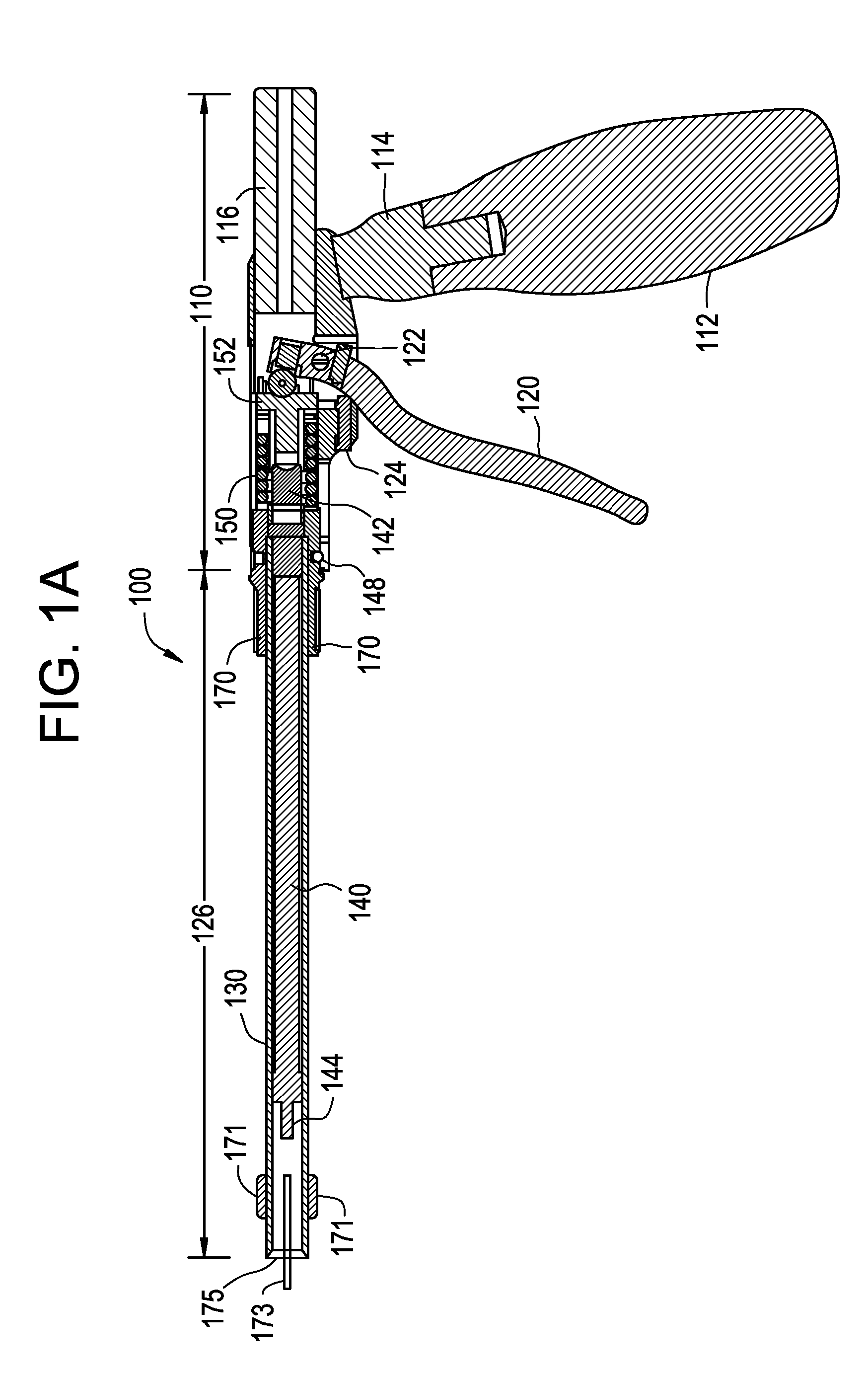

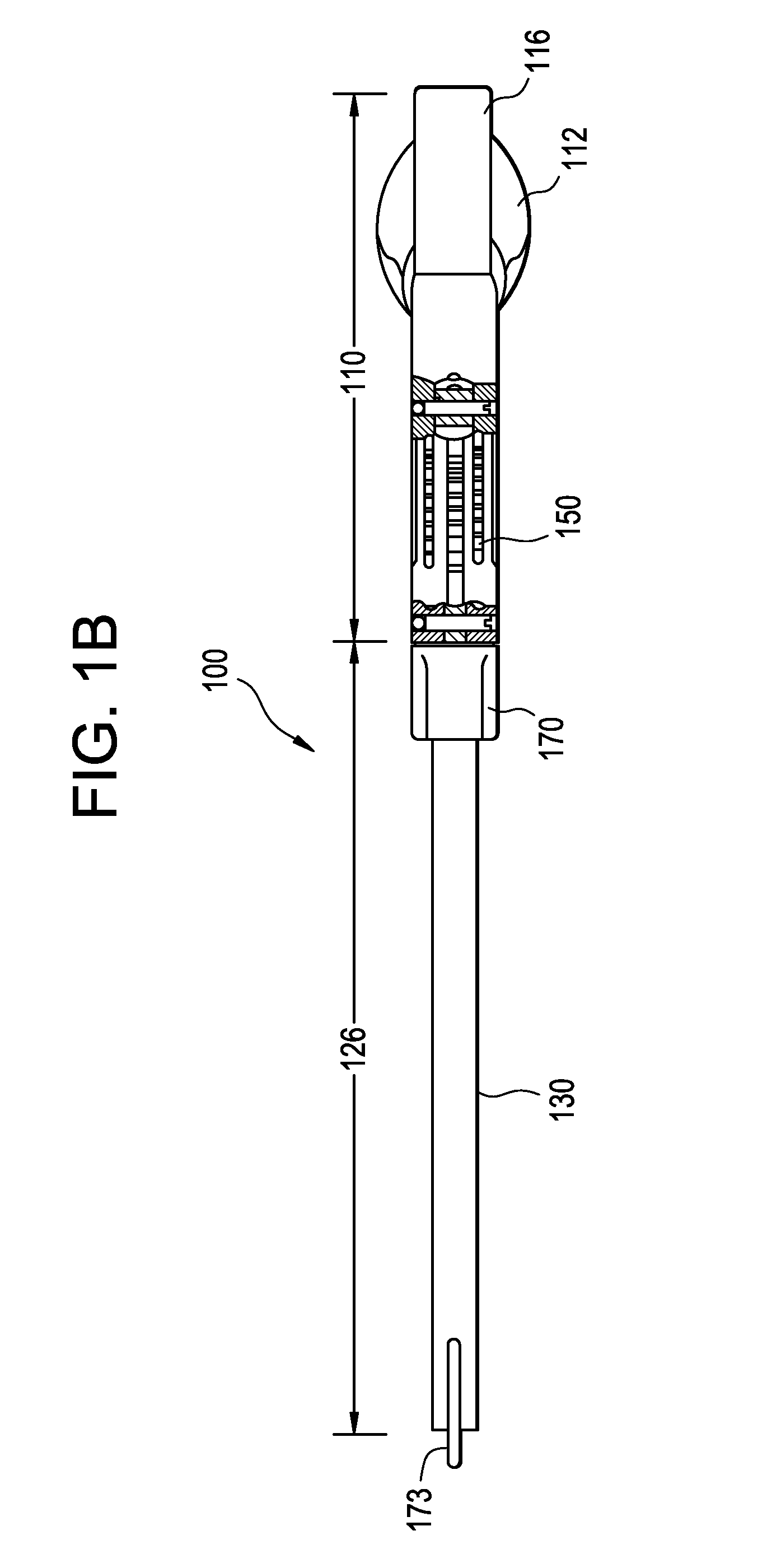

[0039]The foregoing and other objects, features and advantages of the invention will be apparent from the following more particular description of preferred embodiments of the invention, as illustrated in the accompanying drawings in which like reference characters refer to the same parts throughout the different views. The same number appearing in different drawings represents the same item. The drawings are not necessarily to scale, with emphasis instead being placed upon illustrating the principles of the invention.

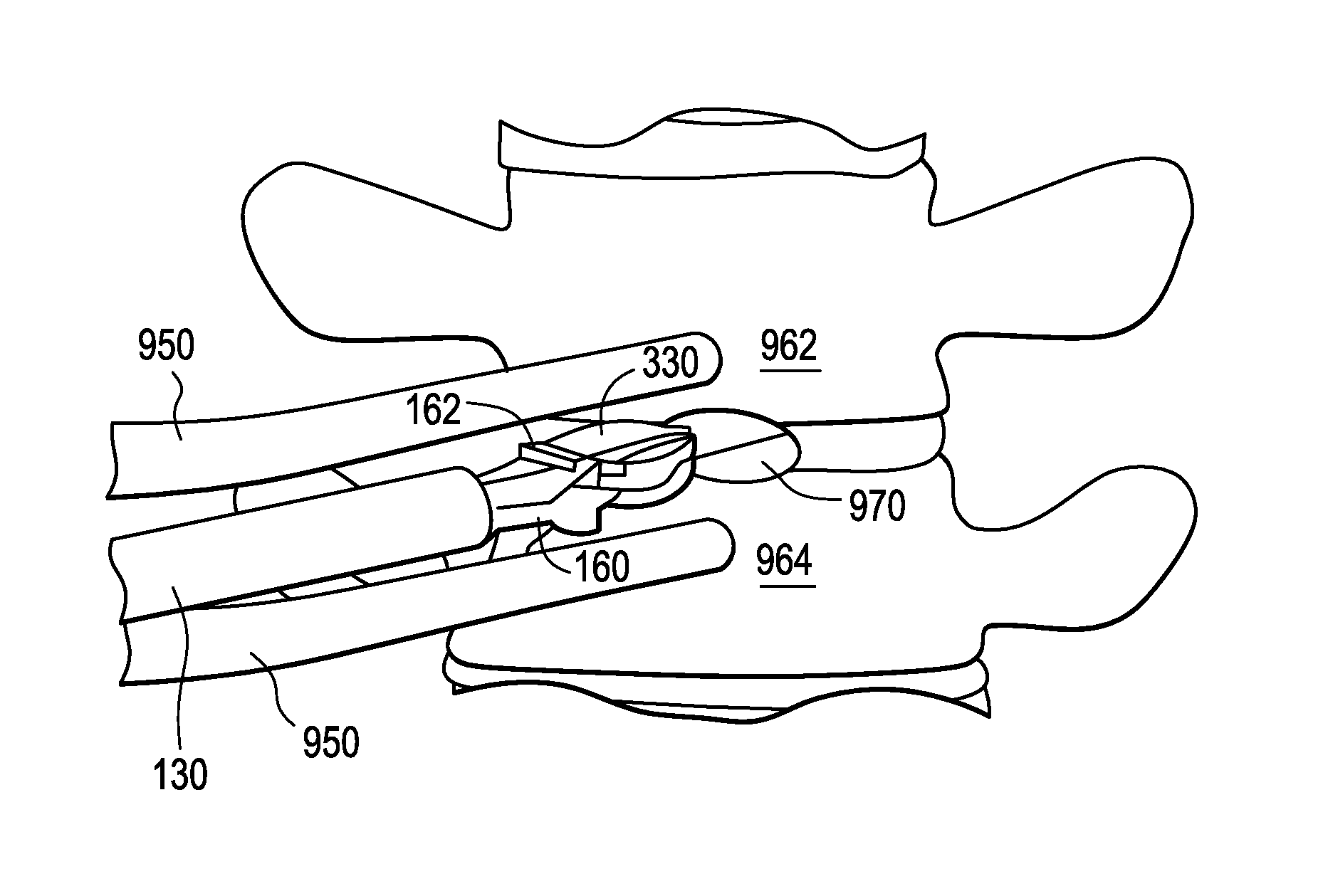

[0040]In general, the present invention is related to an apparatus and a method for safely inserting an implant into a spine. The implant can be an artificial disc or spinal fusion cage, or a spinal plate. Referring to FIGS. 1A and 1B, insertion instrument 100 is shown in a side cross-sectional view and a plan view, respectively. Insertion instrument 100 includes a frame or driver body assembly 110, an actuator assembly 126 and a forked inner shaft 160 (FIG. 2A-2C). In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com