Protective helmet; Method for mitigating or preventing a head injury

a protective helmet and head technology, applied in protective equipment, protective gear, hats, etc., can solve the problems of round helmets, no protection, no success on the market, etc., and achieve the effect of mitigating or preventing a head injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

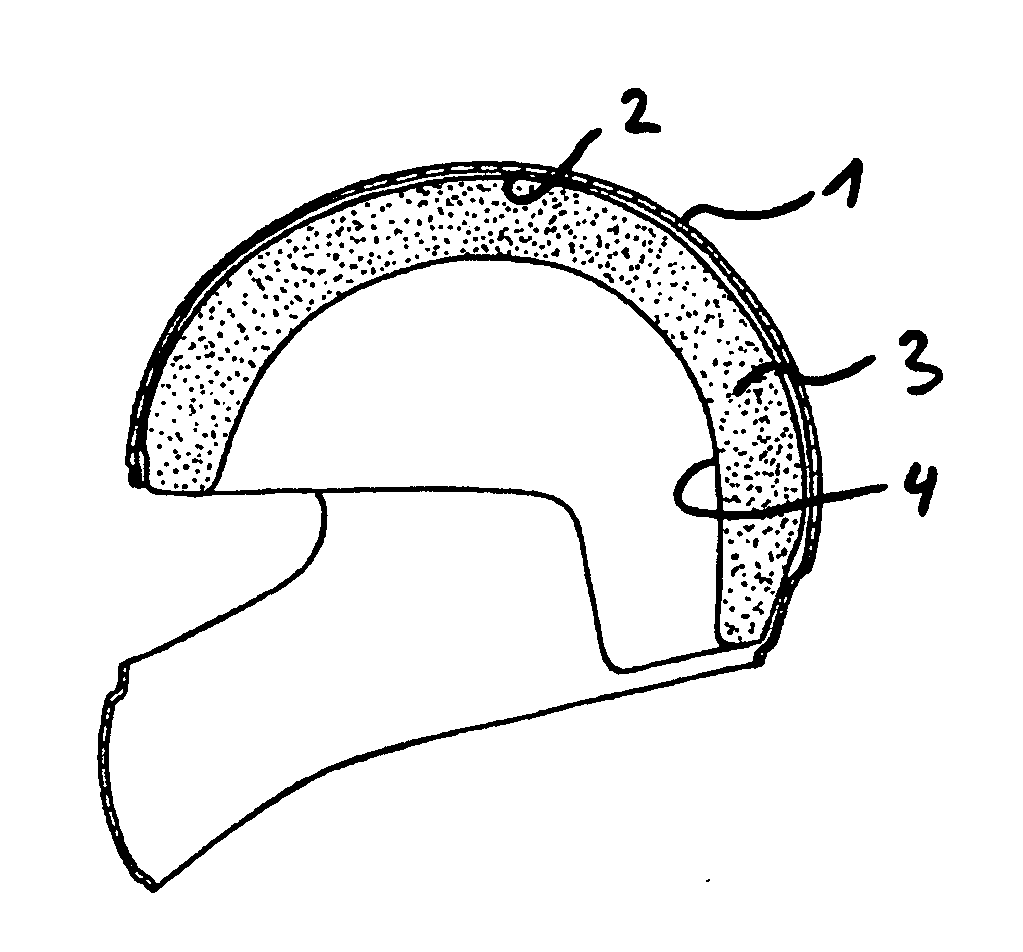

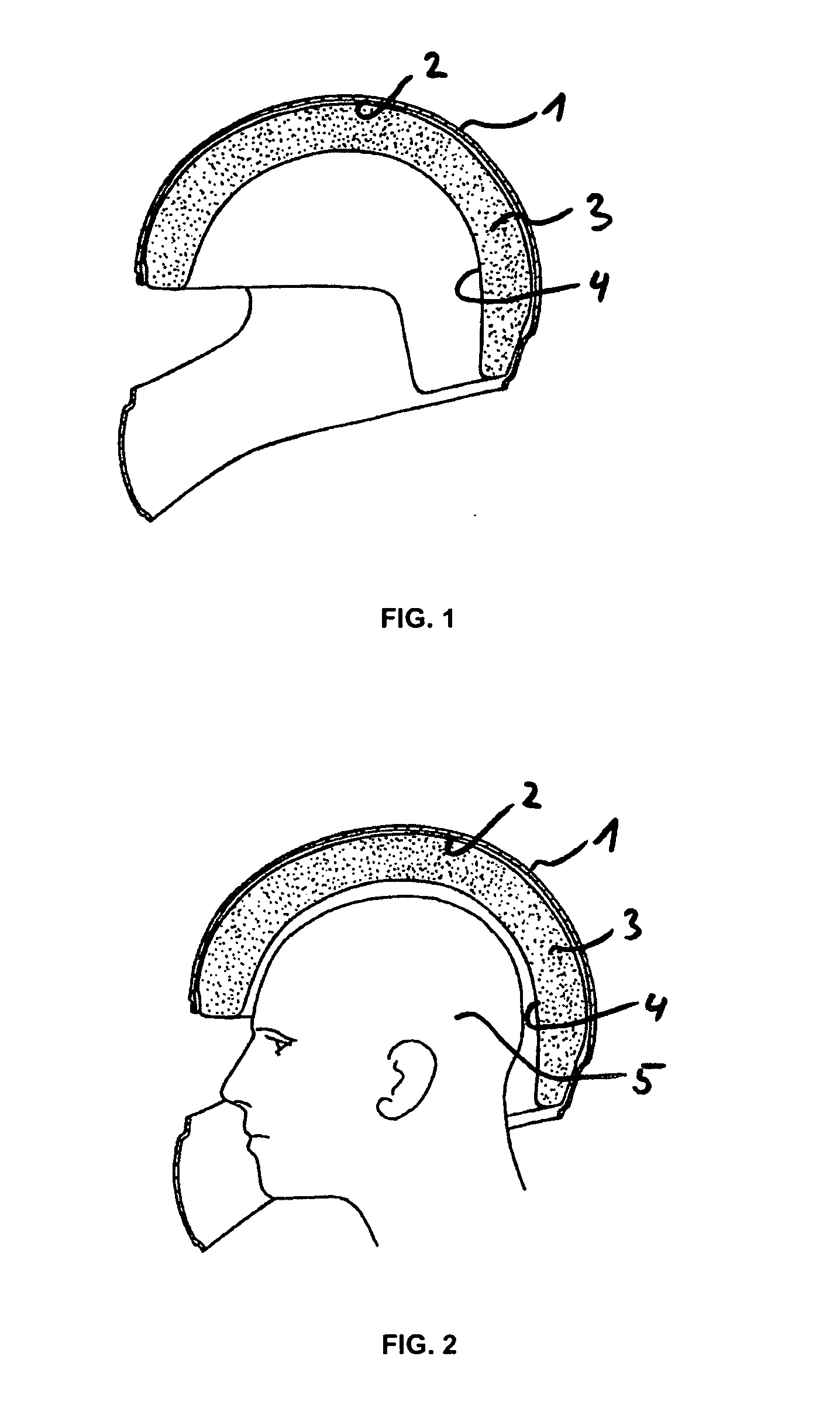

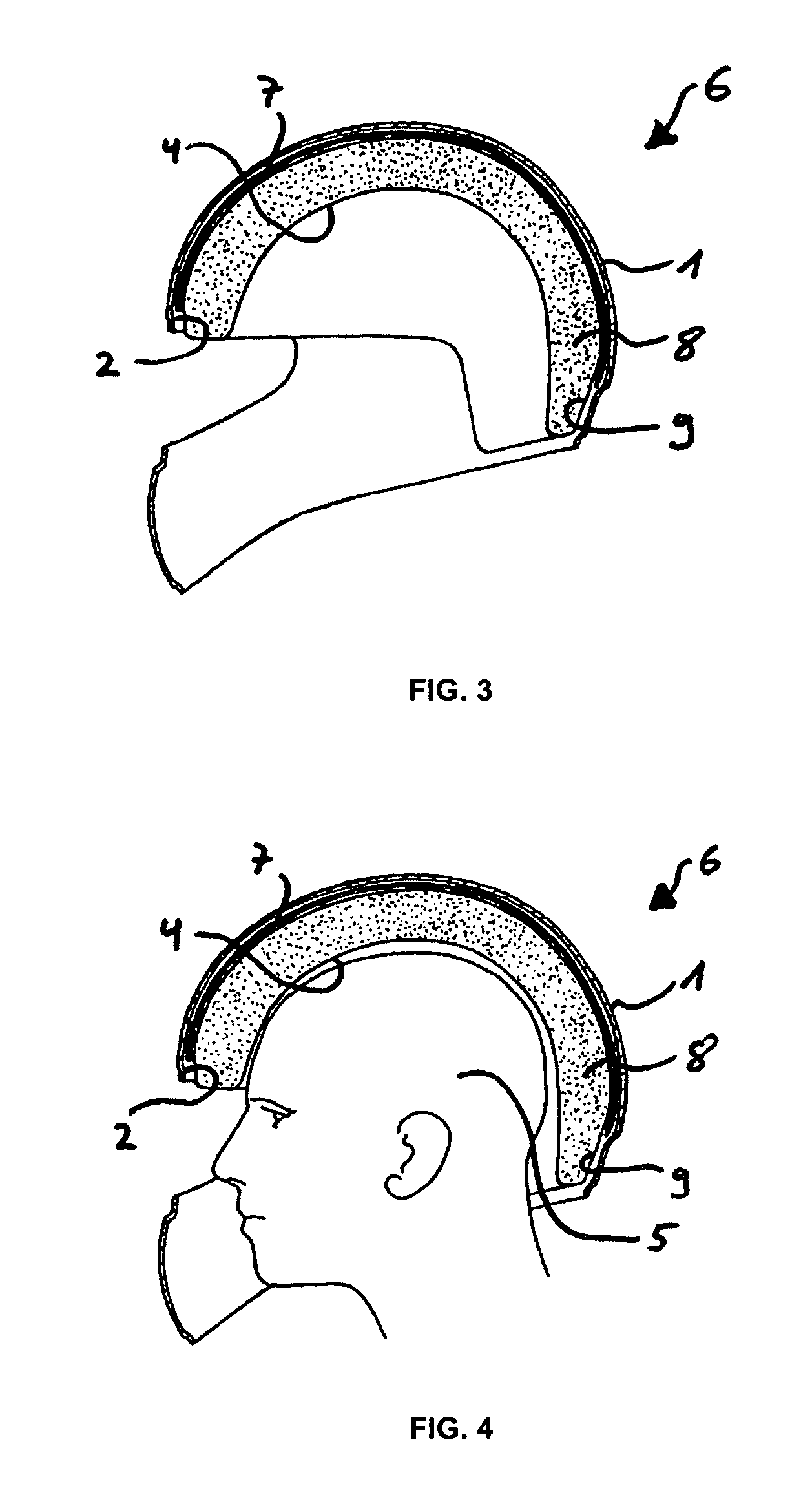

[0053]FIG. 3 and FIG. 4 show sectional views of a protective helmet 6 according to the invention. The shock-absorbing, or shock-absorbing and comfort-providing, inner wearing unit surrounded by the hard outer shell 1 is divided into a shell-side insert 7 and a head-side insert 8, with the outer face 9 of the head-side insert 8 that faces away from the head 5 (see FIG. 4) having a spherical surface at least in some regions, and the outer face 9 of the head-side insert 8 corresponding to the inner face 2 of the shell-side insert 7.

[0054]The shell-side insert 7 and the head-side insert 8 of the inner wearing unit are preferably connected to one another so that they can be displaced freely relative to one another in all directions, whereby they form a displaceable system. Preferably, after displacement, this is restored to the starting position. This can be effected, for example, by an elastic layer or an elastic band. To this end, the trigger force of the system is always less than the...

second embodiment

[0055]FIG. 5 shows an exploded view of a protective helmet 6 according to the invention. In this embodiment, an intermediate layer 10 is disposed between the head-side insert 8 and the shell-side insert 7, this layer comprising an inner face 11 and an outer face 12 and preferably being produced from a harder material. The outer face 13 of the shell-side insert 7 corresponds to the inner face 2 of the outer shell 1. Likewise, the inner face 2 of the shell-side insert 7 corresponds to the outer face 12 of the intermediate layer 10, and the outer face 9 of the head-side insert 8 corresponds to the inner face 11 of the intermediate layer 10. The intermediate layer 10 is rigidly connected to the shell-side insert 7 or the head-side insert 8.

[0056]FIG. 6 and FIG. 7 show sectional views of the protective helmet 6 according to the invention of FIG. 5. The shell-side insert 7 can be rotated around a pivot 14 on the head-side insert 8.

[0057]FIG. 8 to FIG. 10 show the operating principle of th...

third embodiment

[0059]FIG. 12 shows a sectional view of a protective helmet 6 according to the invention. Here, the head-side insert 8 and the shell-side insert 7 are connected to one another by connecting means 20. The connecting means 20 comprise predetermined breaking points 21, which rupture, for example, during a blow from the front, so that the head-side insert 8 rotates backward, together with the outer shell 1, around the pivot 14 in the direction of the arrow 19 (FIG. 13).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com