Reinforced fan frame structure

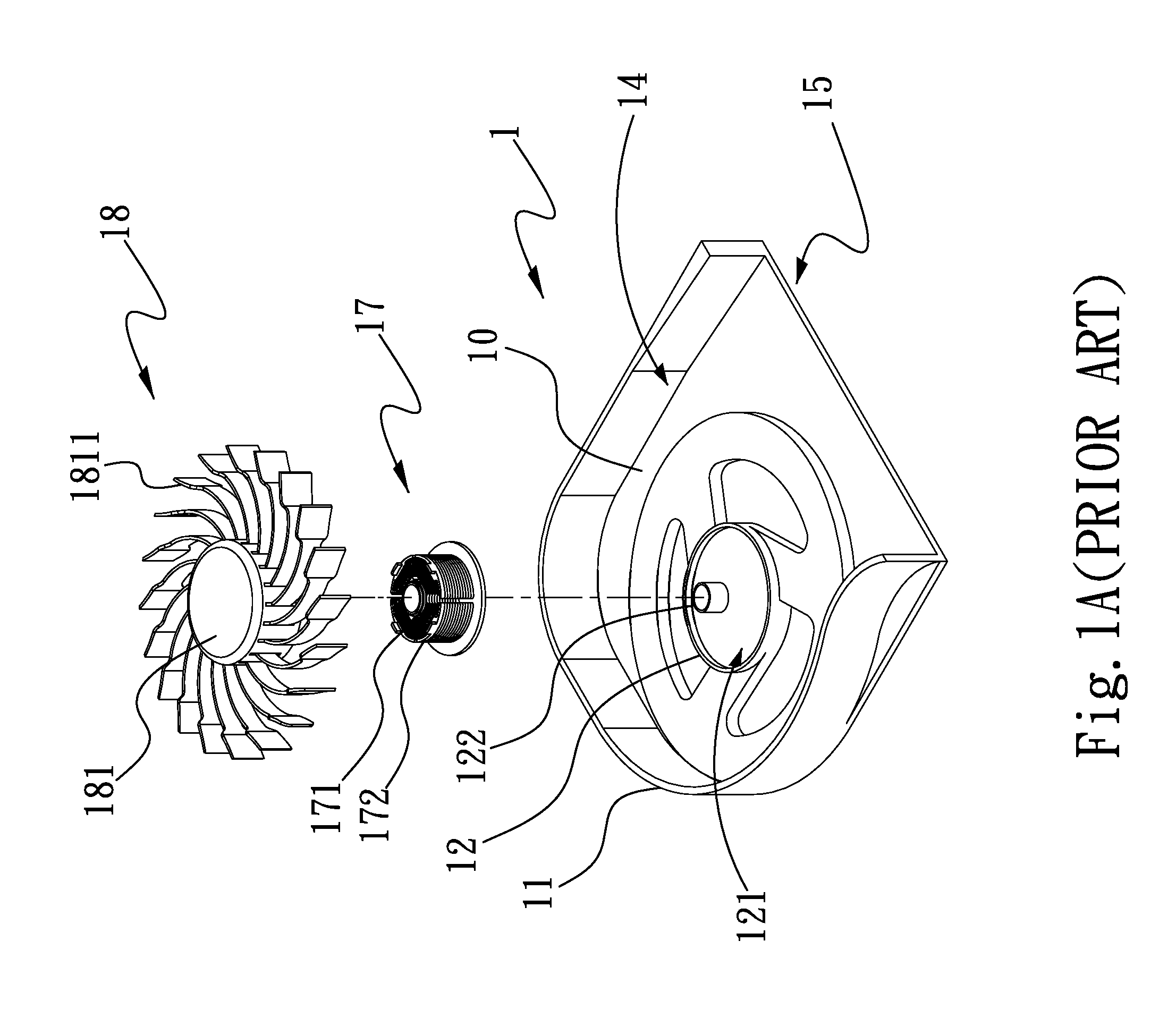

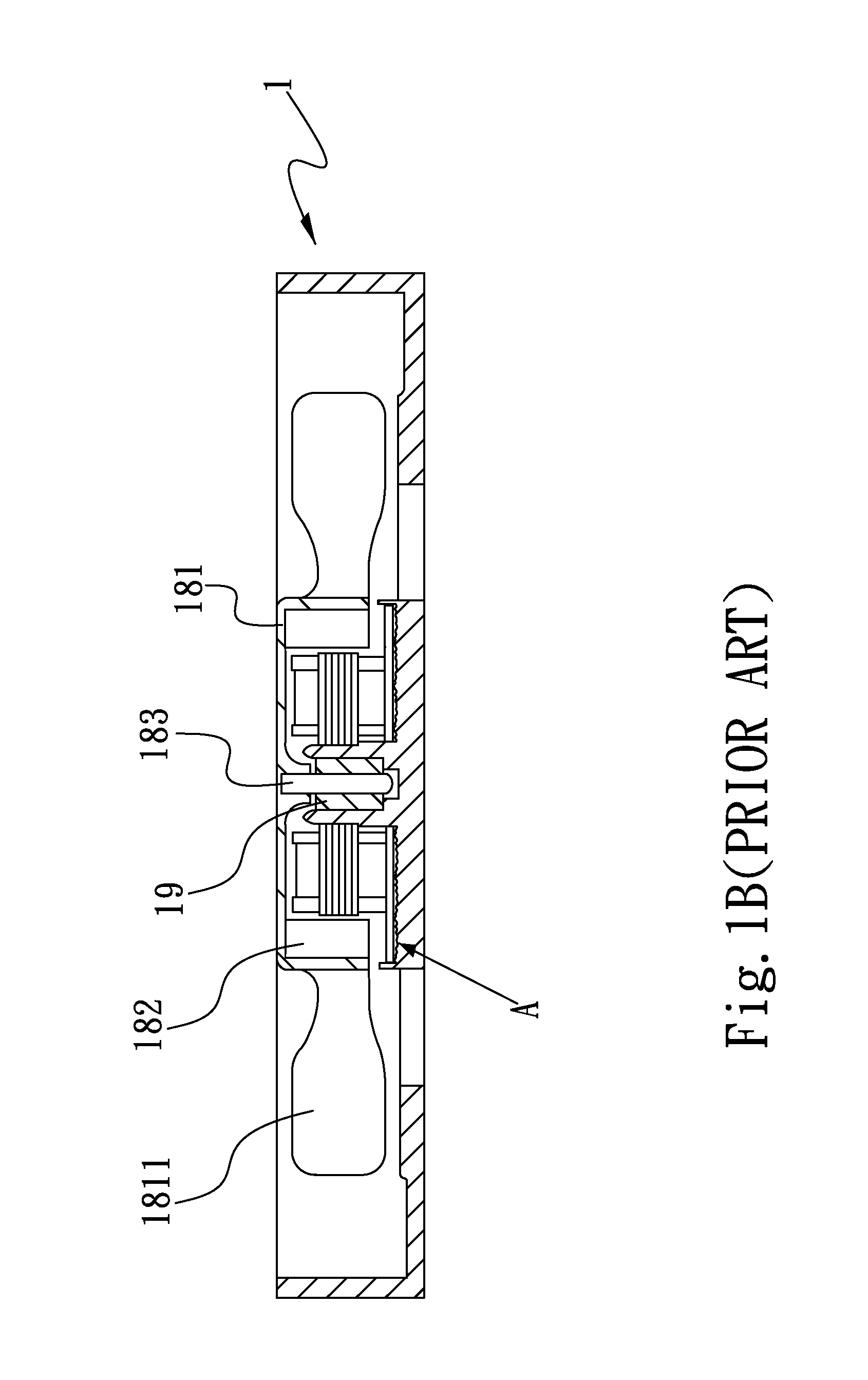

a fan frame and reinforcement technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of poor overall structural strength, the flatness of the seat portion b>12/b> just cannot be controlled to achieve the required specifications, and the conventional fan frame structure, etc., to achieve the effect of effective upgrading the overall structural strength of the seat portion, reducing the risk of damage, and reducing the damage to the frame body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

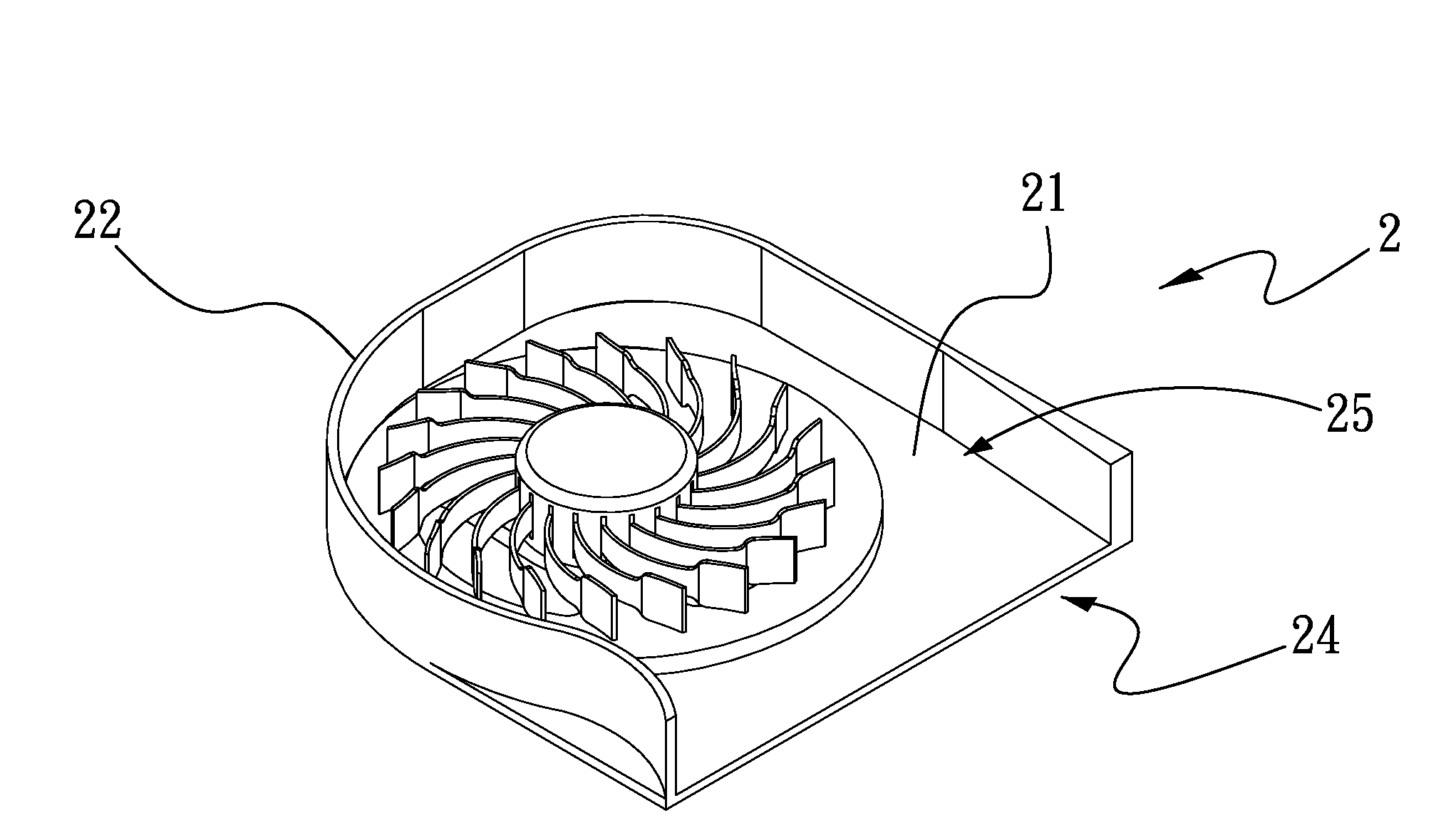

Please refer to FIGS. 2, 3, and 4 at the same time. A reinforced fan frame structure according to a preferred embodiment of the present invention includes a frame body 2 and at least one metal ring 3. The frame body 2 has a seat portion 20, a bottom portion 21, and a wall portion 22. The wall portion 22 is extended along an outer periphery of the bottom portion 21 to vertically rise from substantially three sides of the bottom portion 21, such that a receiving space 25 is defined in the frame body 2 by the wall portion 22 and the bottom portion 21. The seat portion 20 is located in the receiving space 25, and is provided with a centered and axially protruded bearing cup 201. The seat portion 20 is enclosed in an annular wall 202, so that an open-topped recess 204 is defined on the seat portion 20 within the annular wall 202. The metal ring 3 is located in the recess 204 and is integrally associated with the seat portion 20. More specifically, the metal ring 3 is disposed in the rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com