Internal combustion piston engine with an adjustable inflating element

a technology of inflating element and internal combustion piston, which is applied in the direction of valve details, non-fuel substance addition to fuel, exhaust gas recirculation, etc., can solve the problems of high structural complexity, high cost, and strong pressure fluctuations, and achieves low cost and simple measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

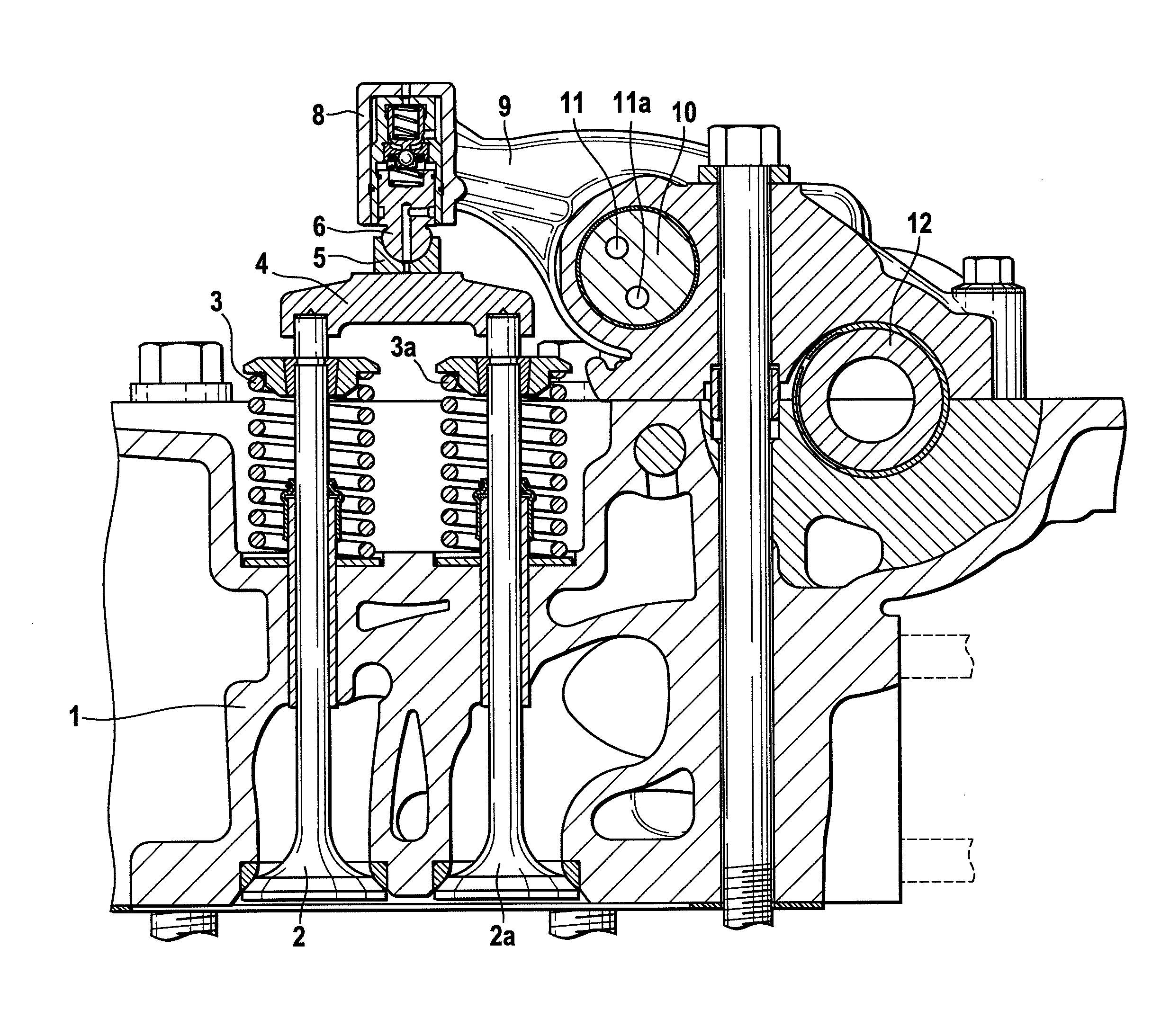

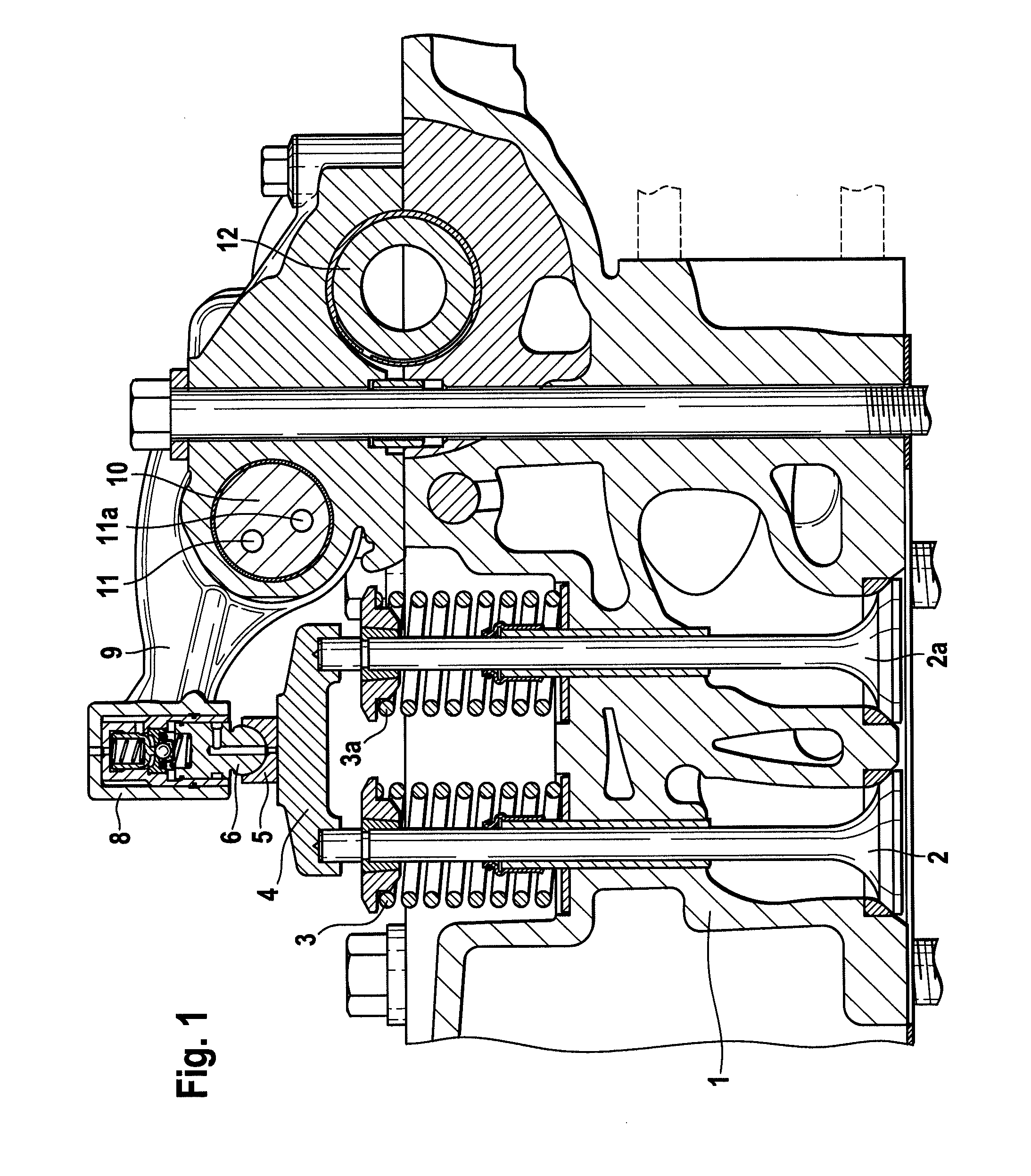

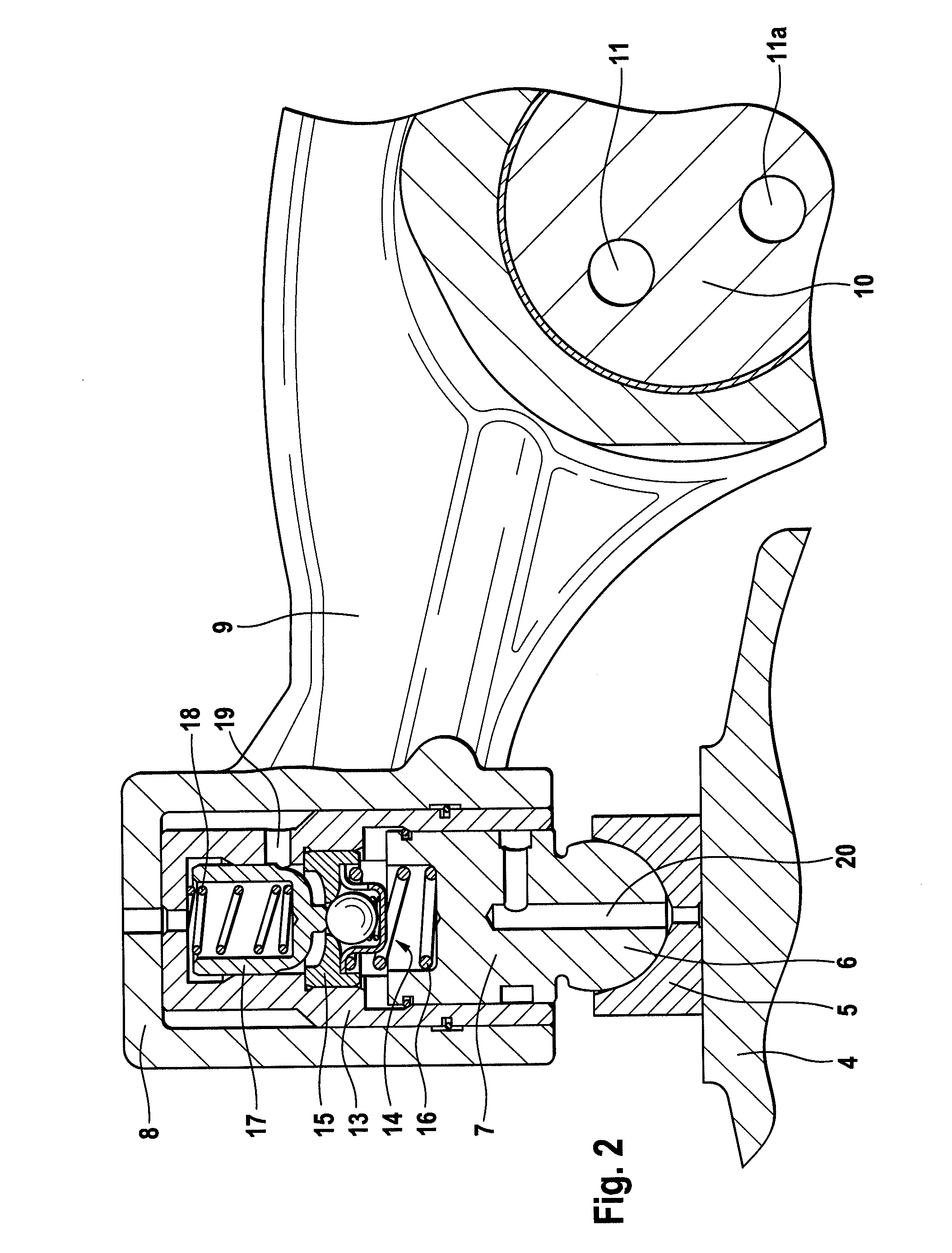

[0019]In FIGS. 1 and 2 a cylinder head of an internal combustion piston engine, as far as specifically shown, is identified at 1. The exhaust channels of the engine are controlled by two exhaust valves 2 and 2a that are guided in the cylinder head 1 and biased in closing direction by valve springs 3 and 3a. A bridge 4 is associated to the valve stems of the exhaust valves 2 and 2a and engages around the ends of the valve stems while being operatively connected to a ball socket 5 supported on a ball head 6 of a working piston 7 which is a component part of an inflating element generally identified at 8. The inflating element 8 is installed in a recess of a rocker arm 9 and supplied with oil from an oil bore in the rocker arm 9, not specifically shown. The rocker arm 9 is mounted on an axle 10 comprising oil channels 11 and 11a which are connected to the oil circulation of the internal combustion piston engine. The oil pressure delivered to the inflating element 8 can be varied throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com