Floating Buildings

a floating building and basement technology, applied in floating buildings, non-magnetic metal hulls, pontoons, etc., can solve the problems of difficult finding suitable land for development, difficult to meet the needs of large-scale construction, and restrict the choice of location, so as to achieve the effect of large size and weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

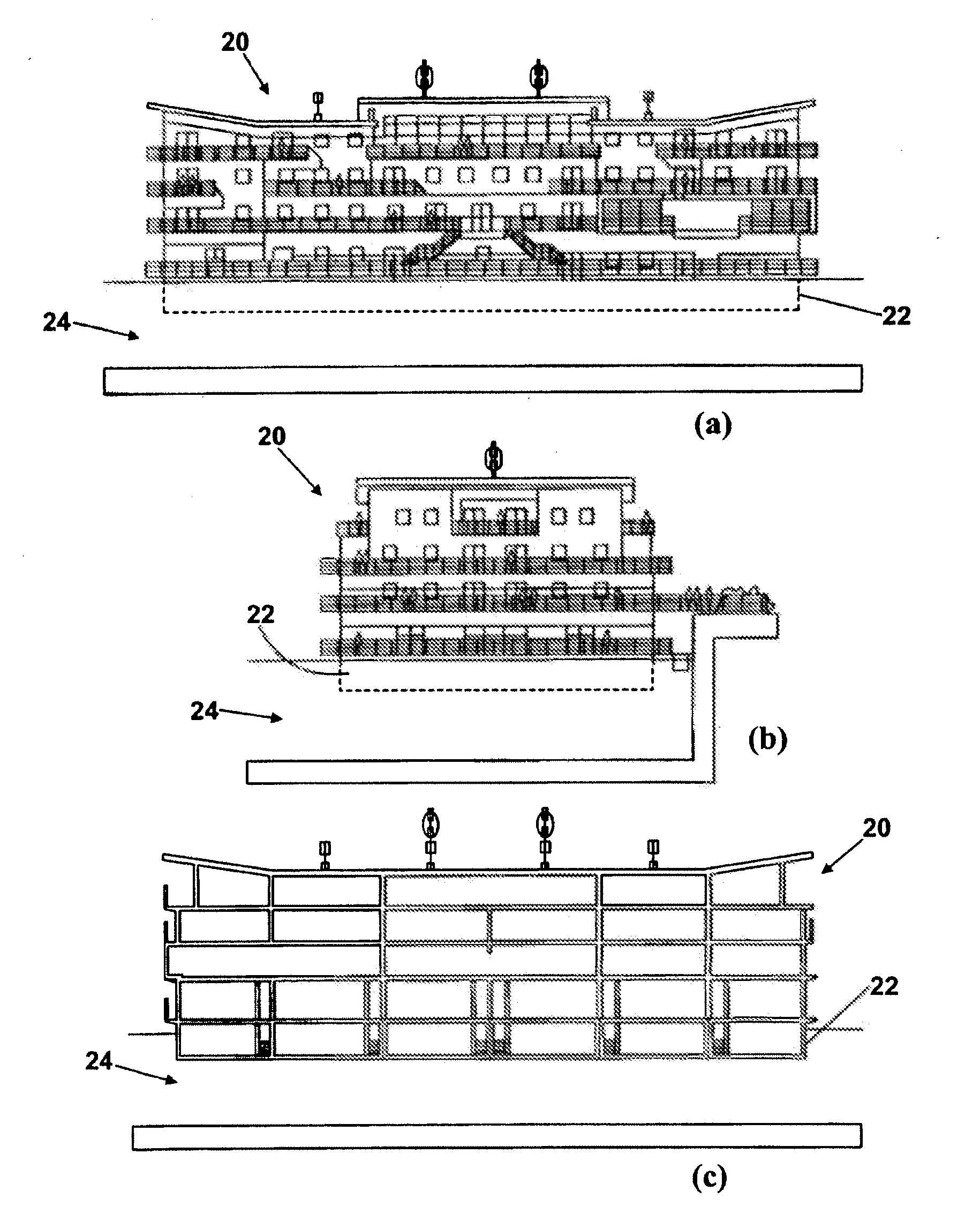

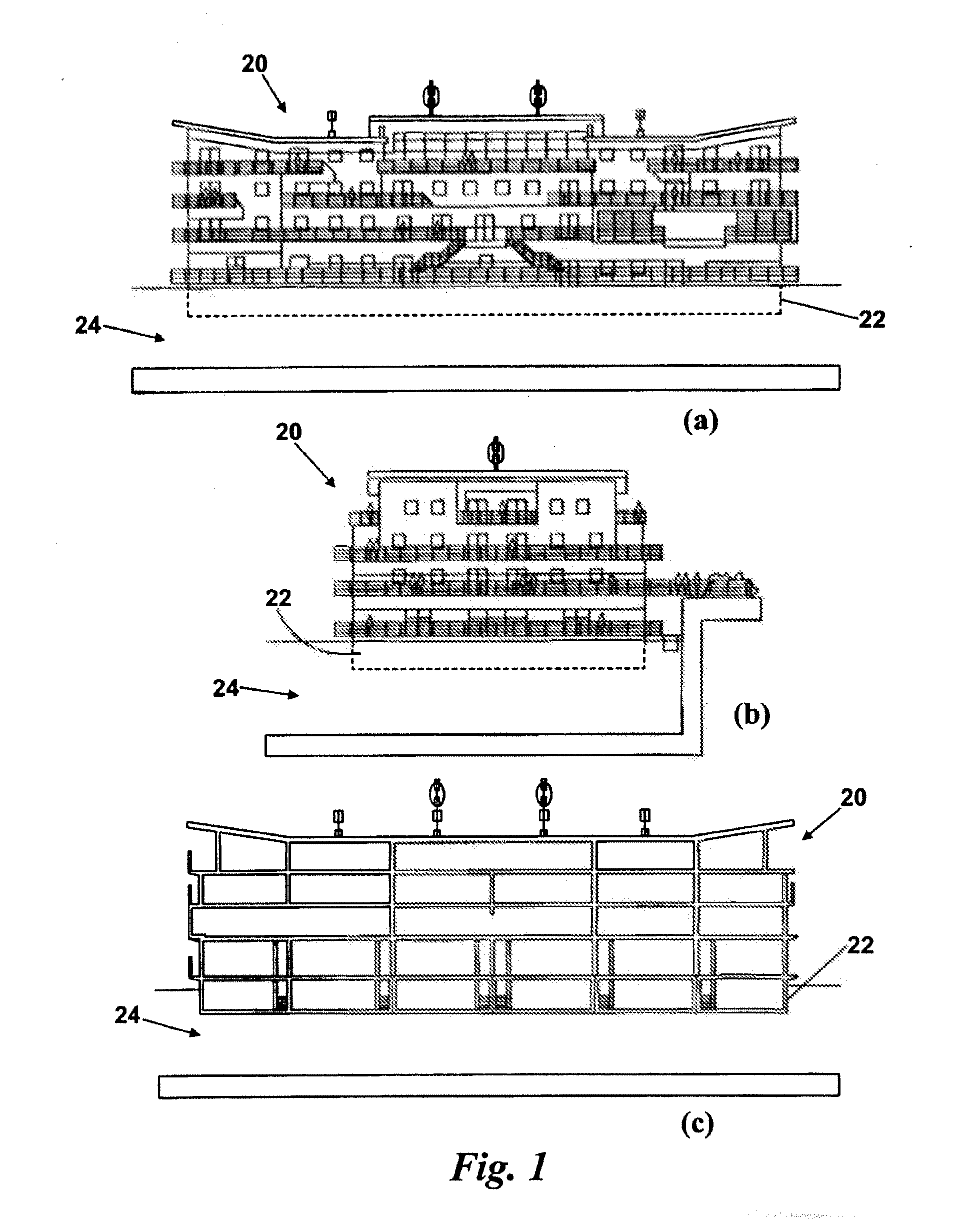

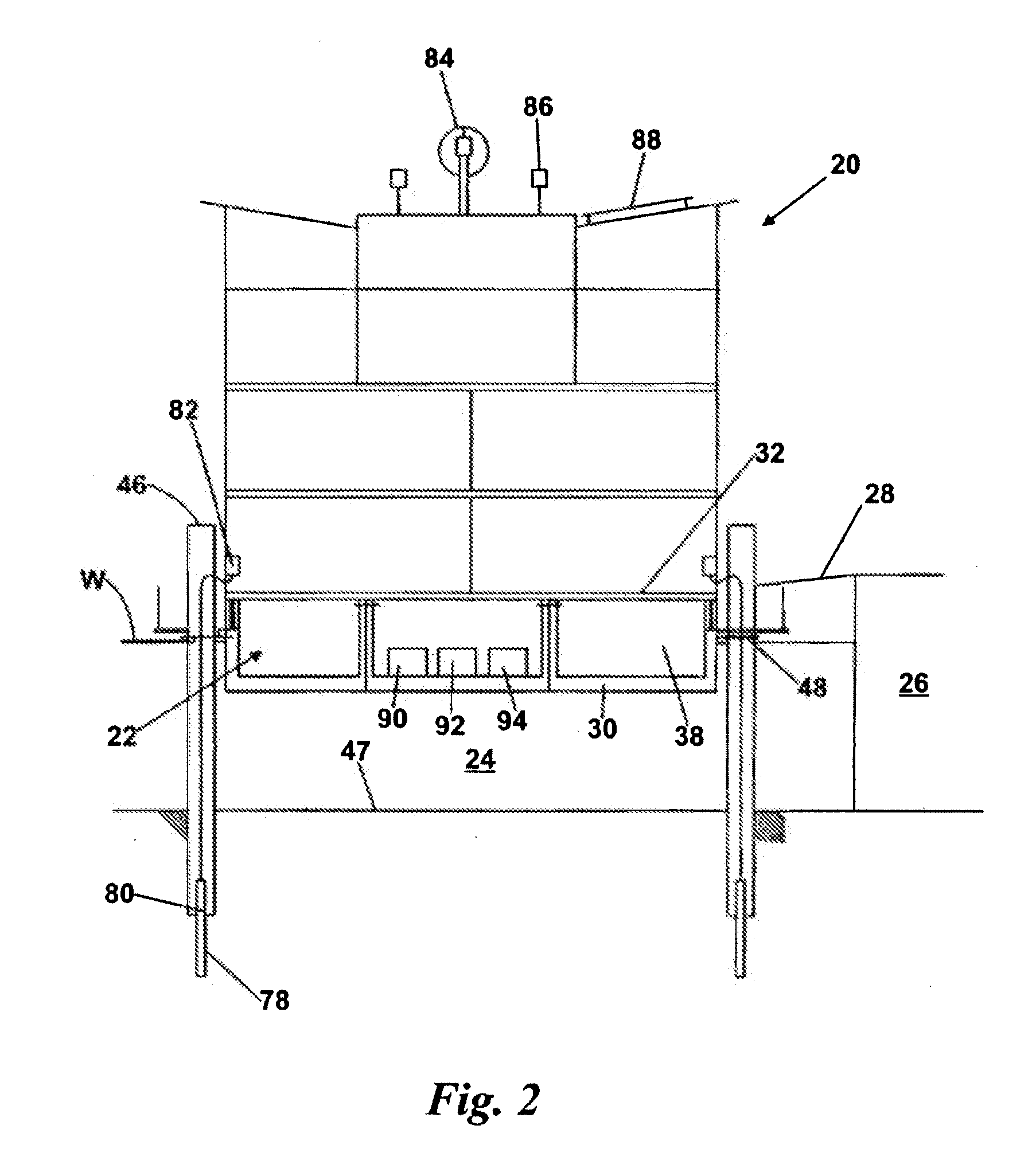

[0085]FIGS. 1 (a) to 1 (c) show a building according to the present invention. The building comprises, in broad terms, a superstructure 20 which is built atop a buoyant basement structure 22 which floats in a body of water 24, such as river, dock, harbour, lake, sea and so on. The buoyant basement structure 22 therefore provides a floating base upon which the superstructure 20 is constructed and supported. The basement structure 22 is shown partially submerged in water in FIGS. 1 (a) to 1 (c).

[0086]In this example, the building is arranged to provide hotel facilities, including bedrooms, bathrooms, communal areas such as leisure facilities and restaurants, and service areas such as kitchens, laundries and plant rooms. Additionally, access routes between the various rooms and spaces are provided.

[0087]Although the example of a floating hotel will be used throughout the remainder of this description, it will be appreciated that such a building could be used for substantially any funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com