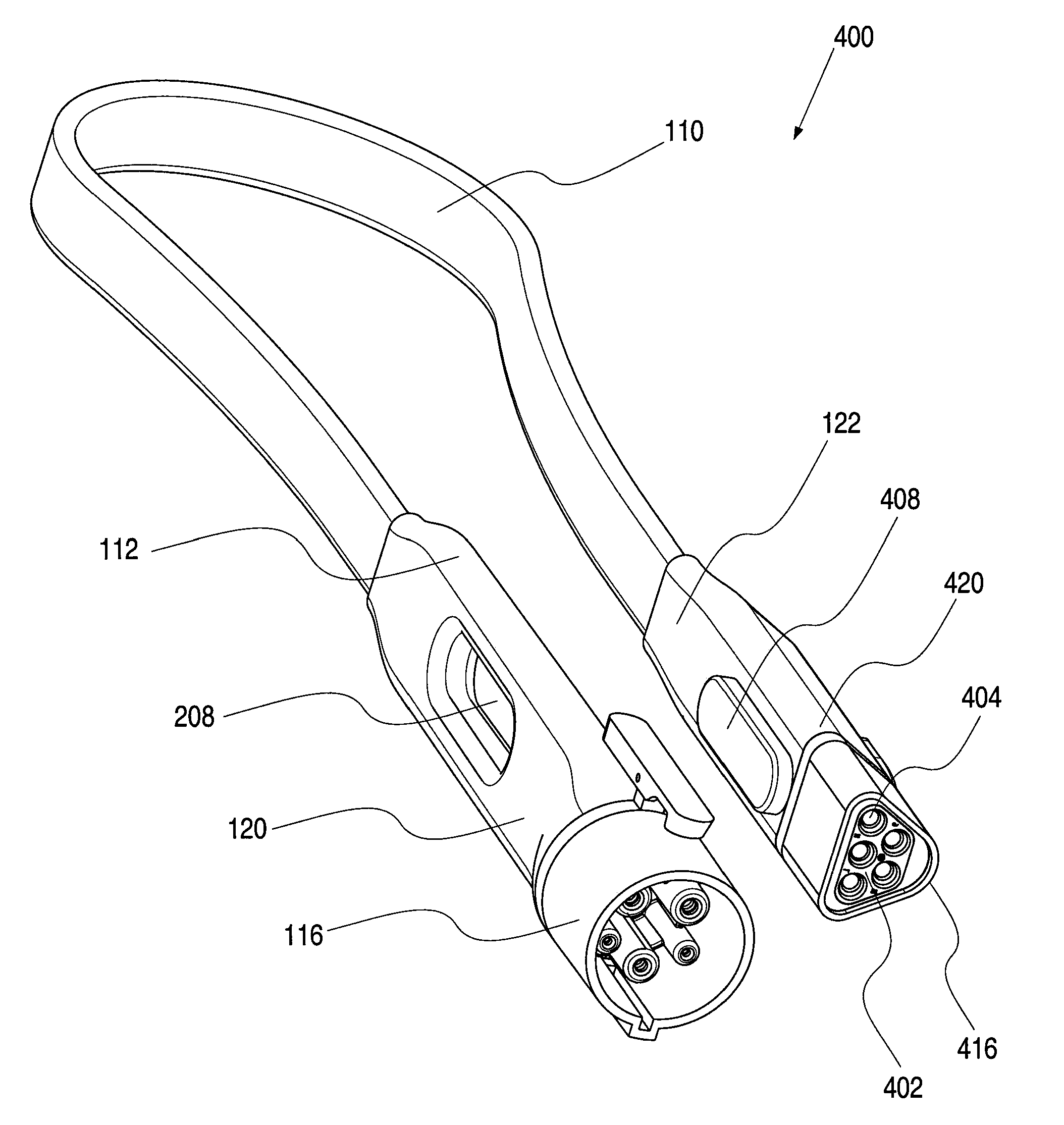

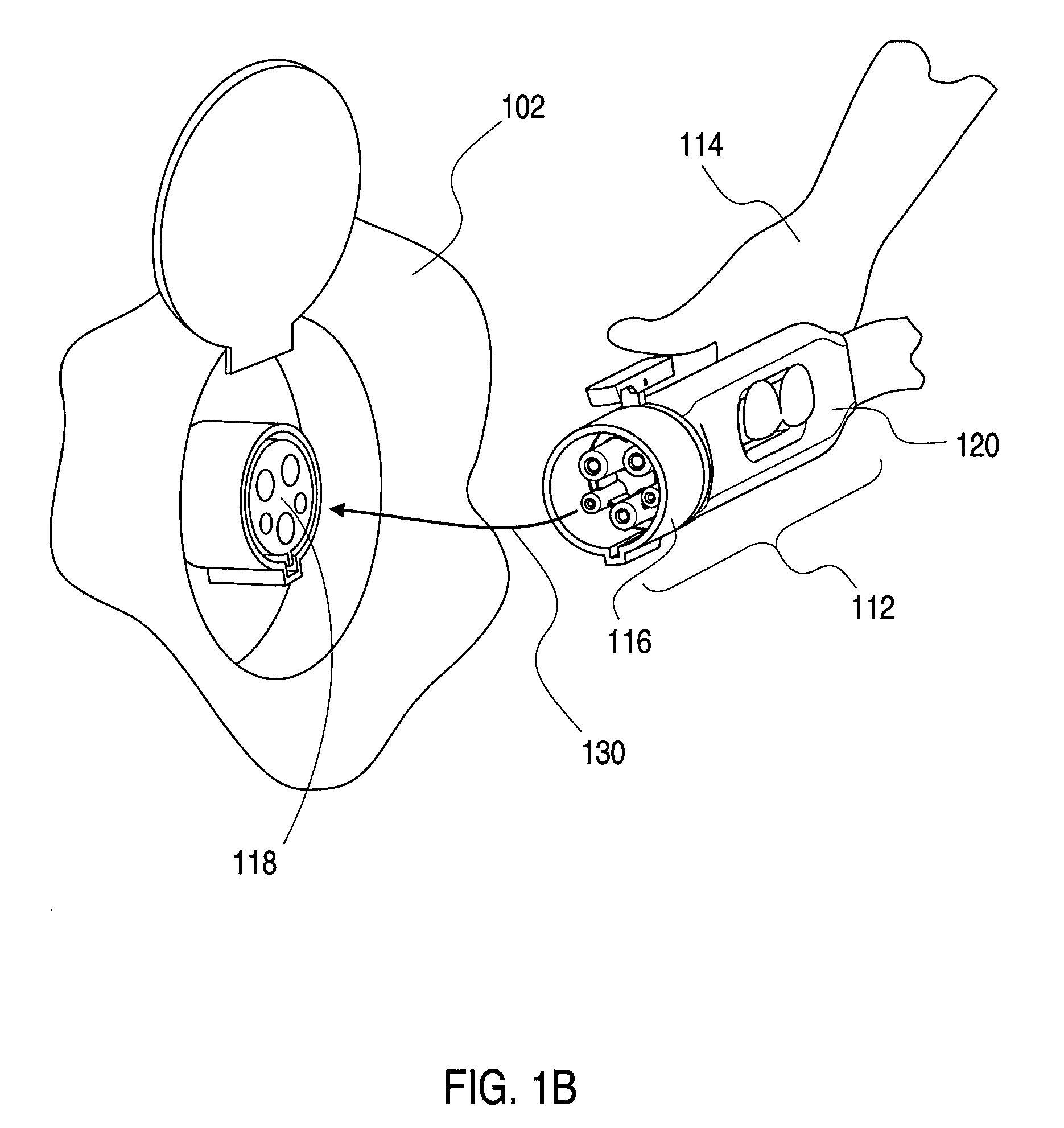

An electrical connector with a flexible blade-shaped housing with a handle with an opening

a flexible, blade-shaped technology, applied in the direction of electrical vehicle, coupling device connection, capacitor propulsion, etc., can solve the problems of limited foreign sources, unable to eliminate the need for fossil fuels for gasoline-electric hybrid vehicles, and long time to widespread commercial use, so as to overcome the frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]One way to address various drawbacks with fossil fuels, like oil which is typically used to power vehicles, is to use vehicles with electric motors. In some embodiments, electric motors can also be powered by rechargeable batteries. Rechargeable batteries can be used to power other devices besides vehicles. In both cases, current rechargeable battery technology typically requires hours for the batteries to recharge.

[0026]As charging of an electric vehicle takes a significantly longer period of time than filling a gas powered vehicle with gas, the owner or operator of the vehicle is unlikely to remain with the vehicle for the entire recharging operation. Sometimes the vehicle will be located in a user's home or private parking garage or lot where it is protected from most malicious or accidental inference. However, some vehicle charging stations are located in public places such as public parking lots, along public streets, or in public parking garages. Some of these public are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com